Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the culinary landscape evolves, so does the equipment we use to create our favorite dishes. One such innovation that has quietly transformed the world of baking is the 220V industrial waffle maker. This versatile appliance has been making waves in both commercial and home kitchens alike, offering a unique blend of power, precision, and convenience. In this exploration, we delve into the world of these waffle makers, uncovering the features that set them apart, the market trends propelling their popularity, and the impact they’re having on the catering and hospitality industry. Join us as we explore the evolution of waffle-making and the exciting possibilities that lie ahead.

The culinary landscape is ever-evolving, and the rise of the industrial waffle maker has been nothing short of revolutionary. Once a staple of home kitchens, the waffle iron has now transformed into a powerful tool in commercial settings, redefining the way we think about breakfast and beyond. This surge in popularity can be attributed to several factors, all contributing to the industrial waffle maker’s newfound status as a game-changer in the kitchen.

Once limited to the humble home setting, the industrial waffle maker has stepped into the spotlight, offering a level of efficiency and precision that was once unimaginable. These machines are not just for producing breakfast favorites; they have become a versatile piece of equipment that can cater to a wide range of culinary creations. From gourmet Belgian waffles to creative savory options, the possibilities are as limitless as the imagination of the chef.

The key to this transformation lies in the robust design and advanced technology of these industrial waffle makers. Engineered to handle high-volume production, they are built to withstand the rigors of commercial kitchens. The robust construction ensures that these machines can consistently deliver the perfect waffle, time and time again, without compromising on quality or speed.

One cannot overlook the convenience factor. With a 220V power supply, these waffle makers heat up rapidly, allowing for a quick turnaround between waffles. This efficiency is crucial in a busy kitchen where every minute counts. Chefs can now serve fresh, warm waffles in record time, keeping patrons satisfied and queues moving smoothly.

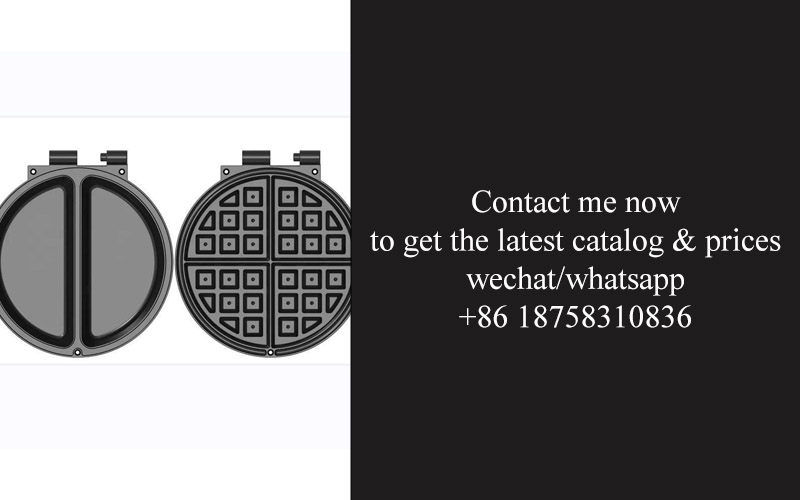

Moreover, the versatility of industrial waffle makers is a game-changer in its own right. They are not just for sweet treats; many models come with interchangeable plates, enabling chefs to craft everything from savory waffles with cheese and ham to innovative dishes that blend sweet and savory flavors. This adaptability makes the industrial waffle maker a must-have for any kitchen looking to offer a unique menu item.

The market trends are clear: there is a growing demand for high-quality, efficient, and versatile kitchen equipment. The industrial waffle maker has capitalized on this trend, becoming a staple in restaurants, cafes, and catering services around the world. Its ability to enhance the menu and improve service efficiency has made it a sought-after tool among culinary professionals.

Another factor fueling the rise of the industrial waffle maker is the rise of food trucks and pop-up restaurants. These mobile operations often rely on space-saving, energy-efficient equipment that doesn’t compromise on quality. The compact size and powerful performance of these waffle makers make them perfect for these dynamic environments.

For those who are health-conscious, the industrial waffle maker is also a godsend. It allows for the creation of homemade, freshly cooked waffles without the need for excessive oil or butter, which can be found in many pre-packaged or fast-food versions. This not only satisfies the taste buds but also aligns with the growing demand for healthier eating options.

The consumer response has been overwhelmingly positive. People are excited about the new and unique flavors that can be crafted on these industrial waffle makers. From traditional waffles to fusion dishes, the possibilities are endless, and consumers are eager to try them all. This enthusiasm has only fueled the demand for these versatile machines.

Innovation in the kitchen is a constant journey, and the industrial waffle maker is at the forefront of this adventure. It’s not just a piece of equipment; it’s a symbol of the creativity and dedication that goes into every dish prepared. Chefs are now able to push the boundaries of what is possible, and the results are nothing short of amazing.

The rise of the industrial waffle maker is a testament to the power of innovation and the importance of adapting to the needs of both the industry and the consumer. As technology continues to advance, we can only imagine what new and exciting features will be integrated into these machines. The future of the industrial waffle maker looks bright, and its impact on the culinary world is sure to be significant.

In the realm of commercial kitchen appliances, the 220V standard has become a pivotal factor in the operation and efficiency of equipment. This voltage level, which is common in many countries across Europe and Asia, plays a crucial role in determining the performance and reliability of industrial waffle makers. Understanding the implications of the 220V standard is essential for anyone looking to invest in or operate such equipment.

The 220V standard refers to the electrical voltage required to power devices. Unlike residential appliances, which typically operate on a lower voltage of 110V, industrial waffle makers are designed to handle the higher voltage for several reasons. First and foremost, the increased power output allows for a faster cooking process, which is essential in high-volume commercial settings where time is of the essence.

One of the primary benefits of using a 220V industrial waffle maker is the rapid heat-up time. These machines can reach the optimal cooking temperature much quicker than their 110V counterparts, ensuring that a steady stream of waffles can be produced throughout the busy service periods. This efficiency is a game-changer for cafes, restaurants, and catering services looking to keep up with customer demand.

Moreover, the higher voltage means that the waffle maker can maintain a consistent and even heat distribution across the waffle grid. This results in a perfectly cooked waffle with a golden brown exterior and a soft, fluffy interior every time. The precision of the 220V system ensures that the product quality is consistent, which is paramount in maintaining a good reputation among customers.

Another important aspect of the 220V standard is its compatibility with other commercial kitchen equipment. In a well-equipped kitchen, different appliances often need to work in tandem to streamline the cooking process. With a 220V industrial waffle maker, it’s easier to integrate this essential piece of equipment into the existing electrical infrastructure without worrying about compatibility issues or the need for additional transformers.

Safety is also a significant concern in commercial kitchens, and the 220V standard is designed to meet stringent safety regulations. These machines are built with robust construction and safety features to prevent accidents and ensure a secure operation. The higher voltage, when managed correctly, can lead to more reliable and durable appliances that are less prone to breakdowns, reducing downtime and maintenance costs.

In terms of energy efficiency, the 220V industrial waffle makers are no slouches either. Despite the higher voltage, these machines are engineered to consume less energy than their lower voltage counterparts. This is due to the fact that they are designed to operate at peak efficiency, providing the necessary power without unnecessary energy waste. For businesses looking to reduce their carbon footprint and operating costs, this is a significant advantage.

The 220V standard also opens up a world of design possibilities for industrial waffle makers. Manufacturers can incorporate advanced features and technologies that would be impractical or inefficient at lower voltages. For instance, some models come with digital temperature controls, allowing operators to fine-tune the cooking process to achieve the perfect waffle every time. These features not only enhance the user experience but also contribute to the overall quality of the finished product.

For businesses that cater to a diverse range of customers, the versatility of 220V industrial waffle makers is invaluable. They can produce waffles in various shapes, sizes, and thicknesses, catering to different preferences and dietary requirements. Whether it’s for a breakfast buffet, a special event, or a themed menu, these machines offer the flexibility needed to keep up with the ever-changing demands of the market.

In conclusion, the 220V standard is a cornerstone of the industrial waffle maker’s success in the commercial kitchen. It provides the necessary power, efficiency, and safety that operators require to produce high-quality waffles consistently. As the demand for waffles continues to grow, understanding the significance of the 220V standard will be key to any business looking to capitalize on this popular trend.

In the realm of commercial kitchen equipment, the industrial waffle maker has emerged as a beacon of innovation. These machines, designed for heavy-duty use, have seen a transformation in their design philosophy, offering functionalities and aesthetics that cater to both the professional chef and the discerning consumer. Here are some of the standout features in the latest wave of industrial waffle makers.

The sleek, modern aesthetic of these waffle makers is a clear departure from the traditional, clunky models of yesteryears. Today’s industrial waffle makers are designed with a clean, minimalist look that fits seamlessly into any commercial kitchen environment. The use of high-quality materials, such as stainless steel and durable plastics, not only enhances the visual appeal but also ensures longevity and easy maintenance.

One of the most significant innovations in industrial waffle makers is the inclusion of adjustable temperature controls. Chefs can now precisely set the heat to achieve the perfect waffle texture, whether they prefer a golden-brown exterior with a soft, chewy interior or a crisp, golden waffle that holds up well in high-heat environments. This feature is particularly valuable for establishments that cater to a diverse clientele with varying preferences.

The size of the waffle plates has also expanded, offering a variety of shapes and sizes to meet different culinary needs. Some models now come with removable plates, making it easier to clean and to switch between different waffle patterns. This versatility is crucial for businesses that want to keep their offerings fresh and exciting without the need for multiple machines.

In terms of functionality, the latest industrial waffle makers often come with a host of user-friendly features. Non-stick surfaces reduce the need for excessive oil, which is not only healthier but also more cost-effective in the long run. The quick-cook capability means that operators can serve a steady stream of waffles without long waiting times, a crucial factor in high-volume operations.

Many modern industrial waffle makers also incorporate safety features that are essential in a commercial setting. Overheat protection and automatic shut-off functions prevent accidents and damage to the equipment, ensuring a safe working environment. Additionally, the inclusion of a drip tray catches any excess oil or batter, maintaining a clean and hygienic workspace.

The design of the handles and controls has also been refined to make the machines easier to use. Ergonomic designs reduce the strain on operators, especially during those busy shifts where efficiency is key. The intuitive control panels allow for easy adjustments without the need for constant monitoring, which is particularly beneficial in bustling kitchens.

In terms of energy efficiency, the latest industrial waffle makers are designed to minimize power consumption without compromising performance. This is not only cost-effective for businesses but also environmentally friendly, a growing concern for many operators.

For those looking to make a statement with their offerings, some industrial waffle makers now come with customizable features. This includes the ability to change the color of the heating elements or even add branded logos, turning a functional piece of equipment into a marketing tool.

Lastly, the integration of smart technology is beginning to make its way into industrial waffle makers. Some models can be controlled remotely via an app, allowing operators to start the machine, check the status, and adjust settings from anywhere in the kitchen. This level of connectivity is a game-changer for busy kitchens that need to manage multiple tasks simultaneously.

In conclusion, the innovation in industrial waffle makers is not just about creating a better product; it’s about enhancing the entire commercial cooking experience. From the sleek design to the advanced features and safety measures, these machines are becoming an essential part of any kitchen that aims to serve up quality waffles in large quantities.

The surge in popularity of 220V waffle makers in the market is not just a fleeting trend; it’s a testament to the evolving demands of consumers and the technological advancements within the culinary industry. Here’s a closer look at why these appliances are making waves.

Users are seeking efficiency and consistency, and 220V waffle makers deliver on both counts. With higher voltage, these machines can operate at faster speeds, ensuring a quicker waffle-making experience. This efficiency is particularly appealing to busy kitchens and commercial establishments where time is a precious commodity.

Gone are the days when waffles were just a weekend treat. Today, the demand for these delightful breakfast items is skyrocketing, thanks to their versatility. From cafes to food trucks, 220V waffle makers are being embraced because they can churn out high-quality waffles in large quantities, meeting the needs of modern diners who are always on the go.

The rise of health-conscious eating habits has also played a significant role. As consumers look for alternatives to traditional breakfast items, waffles, often paired with fresh fruits, yogurt, or even protein, have become a healthier choice. 220V waffle makers, with their ability to produce evenly cooked waffles, are perfectly suited for this trend.

Technology has not only improved the performance of 220V waffle makers but also their design. Modern appliances now come with features like non-stick surfaces, adjustable temperature controls, and even digital displays for precise timing. These innovations make the machines more user-friendly and adaptable to a variety of recipes.

Another key factor in the popularity of 220V waffle makers is their reliability. These appliances are built to withstand continuous use, making them ideal for commercial settings. Their sturdy construction and durable materials ensure a long lifespan, reducing maintenance costs and providing peace of mind for businesses.

Moreover, the market for 220V waffle makers is being driven by the demand for convenience. As life gets busier, consumers are looking for appliances that simplify their cooking processes. These waffle makers, with their straightforward operation and quick clean-up, fit the bill perfectly.

Catering to a global audience, 220V waffle makers are also being influenced by cultural trends. For instance, the growing interest in international cuisines has led to a demand for unique waffle flavors and patterns. Makers are responding with a wider variety of designs, from traditional Belgian squares to heart shapes and even custom imprints.

The market for 220V waffle makers is also being shaped by the rise of e-commerce. With online shopping becoming more accessible, consumers can easily purchase these appliances from the comfort of their homes. This convenience, combined with the variety of options available, has further contributed to the surge in demand.

Lastly, the sustainability movement has influenced the market as well. As consumers become more environmentally conscious, they are seeking appliances that are energy-efficient. While 220V waffle makers typically consume more power, their efficiency and fast cooking times can actually result in overall energy savings, making them a more sustainable choice.

In conclusion, the popularity of 220V waffle makers in the market is a multifaceted trend driven by efficiency, health consciousness, technological advancements, reliability, convenience, cultural influences, e-commerce, and sustainability. As these factors continue to evolve, it’s clear that the demand for these versatile appliances is here to stay.

In the bustling world of commercial kitchens, where efficiency and durability are paramount, the industrial waffle maker has emerged as a staple. To ensure you’re getting the best out of your investment, here are some key features to consider when selecting an industrial waffle maker.

Commercial-Grade Construction The foundation of a reliable industrial waffle maker lies in its sturdy build. Look for units made from heavy-duty materials like stainless steel, which can withstand the rigors of a busy kitchen environment. The exterior should be resistant to heat and corrosion, ensuring longevity.

Even Heat Distribution Consistency is key in waffle making, and an industrial waffle maker with even heat distribution is crucial. Features like non-stick surfaces and multiple heating elements help prevent hot spots and ensure that every waffle is cooked to perfection.

Adjustable Temperature Control Not all waffles are made the same, and an industrial machine should cater to a variety of preferences. Look for models with adjustable temperature settings, allowing you to tailor the cooking temperature to the type of batter or waffle you’re preparing.

Size and Capacity The size of your industrial waffle maker is a significant factor. Consider the space you have available in your kitchen and the volume of waffles you need to produce. Some machines can cook multiple waffles at once, while others are designed for a single batch. The capacity should align with your business’s needs without overcrowding your workspace.

Non-Stick Coating A non-stick coating is a must for easy waffle release and effortless cleaning. This feature not only makes the machine more user-friendly but also reduces the risk of waffles sticking and breaking, preserving the integrity of your product.

Timer and Auto-Off Function A timer is a time-saving feature that allows you to precisely control the cooking time for each waffle. Additionally, an auto-off function adds a layer of safety by shutting off the machine after a predetermined period, even if it’s left unattended.

Easy to Clean Design Kitchens are prone to messes, and an industrial waffle maker should be easy to clean. Look for models with removable plates or grids that can be washed in a dishwasher. The design should facilitate quick and thorough cleaning to maintain hygiene standards.

Power and Voltage Compatibility Ensure that the waffle maker is compatible with the voltage in your kitchen. For commercial use, a 220V model is common, as it provides the necessary power for efficient operation. Check that the machine is designed for continuous use and has a robust power supply.

User-Friendly Controls The controls should be intuitive and easy to use, even in a fast-paced kitchen environment. Digital displays and simple control panels can enhance productivity by allowing for quick adjustments without the need for constant monitoring.

Brand Reputation and Warranty Invest in a brand with a solid reputation for quality and customer service. A good warranty can provide peace of mind, knowing that you’re covered in case of manufacturing defects or malfunctions.

Remember, the best industrial waffle maker for your business will depend on your specific needs, from the type of waffles you plan to produce to the volume of output you require. By focusing on these key features, you can make an informed decision that will serve your kitchen well for years to come.

In the competitive world of commercial kitchen appliances, the 220V waffle makers have been making quite the stir. These machines stand out for several reasons, setting them apart from their counterparts. Here’s a closer look at how they outshine the rest:

The Power of 220VThe 220V rating of these waffle makers translates to a significant boost in power. This higher voltage ensures that the heating elements can reach and maintain optimal temperatures more quickly, resulting in a crispier, more evenly cooked waffle. Unlike their 110V counterparts, 220V waffle makers can often produce multiple batches in a shorter amount of time, making them a favorite among busy commercial kitchens.

Consistent Heat DistributionOne of the challenges with lower voltage appliances is maintaining consistent heat across the entire surface of the waffle iron. 220V models, on the other hand, are designed with precise heat distribution in mind. They often feature non-stick surfaces and even heat distribution systems, which prevent hot spots and ensure that every waffle is cooked to perfection.

Versatility in DesignWhile some waffle makers are limited to the classic Belgian or American style, 220V models often come with a variety of plates to cater to different tastes. From heart-shaped, star-shaped, to even custom designs, these machines can accommodate a wide range of preferences. This versatility not only attracts customers but also adds a unique selling point for food service operators looking to offer a special treat.

Efficient Heating ElementsThe heating elements in 220V waffle makers are typically more robust and efficient. They can quickly heat up and then maintain a steady temperature, which is crucial for high-volume operations. This efficiency not only ensures that waffles are ready promptly but also reduces energy consumption over time compared to appliances that need to cycle on and off to maintain temperature.

Built to LastCommercial kitchens are a tough environment, and the durability of equipment is paramount. 220V waffle makers are often constructed with heavy-duty materials and robust construction, designed to withstand the rigors of daily use. From the handles to the plates, these machines are built to last, reducing the need for frequent replacements and lowering long-term costs.

Safety FeaturesSafety is a top priority in commercial kitchens, and 220V waffle makers are no exception. Many models come with automatic shut-off features that activate when the machine is not in use or when the plates are removed. This not only prevents accidents but also saves energy by cutting off power when not in operation.

Ease of CleaningDespite their commercial-grade build, these waffle makers are surprisingly easy to clean. The non-stick surfaces make it simple to release the waffles, and the durable construction means they can be washed in commercial dishwashers without fear of damage. This ease of maintenance is a significant factor in the overall efficiency of a kitchen operation.

Customization OptionsFor those looking to add a personal touch to their waffle offerings, 220V waffle makers often come with customization options. Some models allow for the use of interchangeable plates, which can be swapped out to create different shapes and sizes of waffles. This level of customization can be a game-changer for businesses aiming to stand out in a crowded marketplace.

Energy EfficiencyContrary to the belief that higher voltage appliances are less energy-efficient, 220V waffle makers can actually be more energy-efficient in the long run. Their ability to heat up quickly and maintain a consistent temperature means they are not left idling for extended periods, which can be a significant drain on energy in commercial settings.

User-Friendly InterfacesThe interfaces on 220V waffle makers are typically straightforward and easy to use. With simple on/off switches and, in some cases, digital controls for temperature adjustments, these machines are accessible to both experienced chefs and those new to waffle-making. This user-friendliness is essential for ensuring a smooth workflow in a busy kitchen.

Customer SatisfactionUltimately, the goal of any commercial kitchen appliance is to improve customer satisfaction. 220V waffle makers, with their superior performance, versatility, and durability, contribute to higher-quality waffles that are ready faster. This leads to happier customers and repeat business for the establishments that invest in these appliances.

In conclusion, the 220V waffle makers are not just a step above their alternatives; they are a leap forward in terms of performance, efficiency, and user satisfaction. Their ability to deliver consistently high-quality waffles in a commercial setting is why they are catching on as the preferred choice for many food service operators.

The integration of 220V industrial waffle makers has significantly transformed the catering and hospitality industry. These machines, known for their robust performance and commercial-grade build, have become a staple in cafes, restaurants, and hotels worldwide. Here’s how they’ve made a lasting impact:

Their Consistent OutputCommercial kitchens demand efficiency and reliability. 220V waffle makers are designed to churn out waffles at a high volume with consistent quality. The powerful heating elements ensure that every waffle is golden brown and perfectly textured, which is crucial for maintaining a high standard of service, especially during peak hours.

Enhanced Cooking SpeedTime is money in the food service industry, and these waffle makers are engineered to cook waffles swiftly. With their rapid heating capabilities, these machines can produce a batch of waffles in a matter of minutes, reducing wait times and keeping lines moving smoothly. This speed of service is particularly valuable in fast-casual and quick-service restaurants where speed and efficiency are paramount.

Versatile Cooking OptionsThe versatility of 220V waffle makers is unparalleled. These machines often come with various plate designs, allowing chefs to create a variety of waffle patterns, from classic Belgian to heart-shaped and even customizable designs. This flexibility means that establishments can cater to diverse customer preferences without the need for multiple machines.

Increased CapacityCommercial kitchens often require high-capacity equipment to handle large crowds. 220V waffle makers are built to handle large batches of waffles, ensuring that even the busiest venues can meet their customers’ demands. The larger plates and efficient cooking process make these machines ideal for buffets, catered events, and large-scale operations.

Improved Hygiene StandardsHygiene is a top priority in the catering and hospitality sector. Industrial waffle makers are designed with easy-to-clean surfaces and components, which help prevent cross-contamination and maintain a clean kitchen environment. This feature is not only crucial for health and safety regulations but also for maintaining a positive reputation among customers.

Cost-Effective OperationDespite their initial investment, 220V waffle makers can be a cost-effective choice for businesses. Their energy-efficient design ensures that they consume less power than their counterparts, leading to lower utility bills over time. Additionally, the durability and longevity of these machines mean that they can be used for years without the need for frequent replacements.

Enhanced Customer ExperienceThe quality of the food and the speed of service directly influence customer satisfaction. With the consistent and quick production of waffles, these machines contribute to a better overall dining experience. Customers appreciate the fresh, hot waffles that these industrial machines produce, which can help create a memorable and enjoyable meal.

Customization and BrandingMany 220V waffle makers come with branding options, allowing businesses to add their logos or messages to the waffles. This level of customization is not just about marketing; it’s also a way to create a unique and memorable experience for customers. It’s a subtle yet effective branding tool that can set a business apart in a competitive market.

Training and MaintenanceThe user-friendly design of these waffle makers makes training staff on their operation straightforward. The clear instructions and intuitive controls ensure that employees can quickly learn how to use the machines effectively. Furthermore, regular maintenance is minimal, with durable parts that require little upkeep, allowing staff to focus on other aspects of service.

Innovation and Technological AdvancementsThe industry of 220V waffle makers is continuously evolving with technological advancements. New models often come with features like adjustable temperature controls, non-stick surfaces for easier release, and digital displays for precise cooking times. These innovations not only improve the performance of the machines but also provide added convenience for operators.

In conclusion, the impact of 220V industrial waffle makers on the catering and hospitality industry is profound. Their ability to produce high-quality waffles at a rapid pace, with versatile designs and ease of maintenance, has become a valuable asset for businesses looking to enhance their service offerings and customer satisfaction. As the industry continues to grow and demand for quality food increases, these machines are likely to play an even more significant role in shaping the future of foodservice.

Home bakers have a lot to say about their experiences with industrial waffle makers, and their insights offer valuable feedback on what makes these appliances stand out. Here’s a glimpse into their world:

The convenience of bulk production is a major talking point. Many home bakers appreciate how these machines can churn out a substantial number of waffles in a short amount of time, perfect for those with a crowd to feed or a desire for a large batch of their favorite treats. Users often note that the consistency in size and texture is unmatched, as these machines are designed for efficiency and precision.

The durability and build quality are consistently praised. Home bakers are impressed with the sturdy construction and the fact that these appliances can withstand heavy use. They often comment on the longevity of the waffle makers, stating that they have outlasted other kitchen gadgets and even replaced multiple domestic models over the years.

The variety of patterns and customization options is a favorite among users. From classic Belgian squares to intricate heart or star designs, the ability to switch out molds is seen as a fun and creative aspect of these industrial waffle makers. Bakers enjoy experimenting with different recipes and toppings, and the versatility of these machines allows for a wide range of culinary adventures.

Users also appreciate the control over heat settings. Industrial waffle makers typically offer adjustable temperature controls, which allows for perfecting the golden brown texture and crispiness of the waffles. This feature is particularly valued by those who are particular about the taste and appearance of their final product.

The ease of cleaning is a common theme in reviews. Despite their larger size and industrial nature, many home bakers find these waffle makers surprisingly easy to clean. The non-stick surfaces are a hit, as they require minimal scraping and the removable plates make the process quicker and more straightforward.

Safety features are another aspect that users find reassuring. With features like cool-touch handles and overload protection, home bakers feel confident using these machines, especially around children or in busy kitchens. The peace of mind that comes with these safety features is often highlighted in positive feedback.

Many bakers also appreciate the value for money. Despite the higher initial investment compared to standard home waffle makers, the long-term cost-effectiveness is a strong selling point. Users often mention that the ability to make large quantities of waffles at a lower cost per serving offsets the higher price tag.

There’s a sense of nostalgia and tradition that comes with using industrial waffle makers. Many bakers find themselves reaching for these machines as they remind them of family gatherings or their own childhood. The emotional connection to these appliances is a powerful factor in their appeal.

In terms of customer service, home bakers have been largely satisfied with the support they receive. Whether it’s through detailed manuals, helpful online resources, or responsive customer service teams, the assistance available for troubleshooting and maintenance is seen as a positive aspect of owning an industrial waffle maker.

Lastly, the social aspect of waffle making is often celebrated. Bakers enjoy the process of making waffles with friends and family, and the communal nature of the activity is something that users feel is uniquely enhanced by industrial waffle makers. The shared experience and the resulting delicious treats are cherished memories for many home bakers.

These insights provide a clear picture of the satisfaction and utility that home bakers derive from their industrial waffle makers. From the practicality of bulk production to the emotional connection to tradition, these appliances have made a significant impact on the home baking community.

The world of industrial waffle makers is evolving rapidly, and the future holds a plethora of innovations that promise to revolutionize the way we think about these kitchen appliances. From smart technology integration to eco-friendly materials, here’s a glimpse into what’s on the horizon for industrial waffle makers.

Innovations in MaterialsManufacturers are increasingly looking to sustainable and durable materials to construct their waffle makers. Biodegradable plastics and recycled metals are becoming more common, reducing the environmental footprint of these machines. The shift towards these materials not only makes them more eco-friendly but also contributes to their longevity, ensuring that industrial waffle makers are built to last.

Smart Technology IntegrationThe integration of smart technology is set to transform the industrial waffle maker market. Imagine a machine that can connect to your kitchen management system, allowing for remote monitoring and control. Features like automatic temperature regulation, real-time performance analytics, and predictive maintenance could become standard, leading to more efficient operations and reduced downtime.

Customization and PersonalizationAs consumer demands grow more varied, so does the need for customization. The future industrial waffle maker might offer a range of interchangeable plates to accommodate different waffle shapes and sizes, catering to niche markets and special dietary requirements. Personalization could extend to programmable settings that allow users to tailor the cooking process to their specific preferences.

Health and Safety FeaturesWith a focus on health and safety, future industrial waffle makers could include advanced safety features. This might involve anti-slip bases, automatic shut-off mechanisms in case of overheating, and clear, easy-to-read control panels to prevent accidents. Additionally, features that promote food safety, such as non-stick surfaces that are easy to clean and sanitize, will become increasingly important.

Energy EfficiencyEnergy consumption is a significant concern for businesses, and the future of industrial waffle makers may see a shift towards greater energy efficiency. New technologies could include programmable timers, energy-saving modes, and advanced insulation to reduce power usage. This not only helps businesses save on their energy bills but also aligns with broader sustainability goals.

Connectivity and Data AnalyticsThe ability to connect to the internet and gather data on usage patterns could become a standard feature. This connectivity would allow for predictive maintenance, where the machine can alert the user to potential issues before they become major problems. Data analytics could also help businesses optimize their production processes, leading to more efficient use of resources.

Modularity and ScalabilityAs businesses grow, their waffle-making needs may change. Future industrial waffle makers may be designed with modularity in mind, allowing for easy upgrades and expansion. This could mean additional stations, larger cooking surfaces, or even the ability to integrate with other kitchen equipment, creating a seamless workflow.

Sustainability InitiativesManufacturers are likely to embrace sustainability initiatives more than ever before. This could involve the use of renewable energy in the production process, the implementation of recycling programs for old machines, and the development of more energy-efficient models. The focus on sustainability is not just about reducing the environmental impact but also about positioning the brand as forward-thinking and responsible.

Interactive Learning and AdaptationSome of the most exciting potential innovations involve the ability for industrial waffle makers to learn from their use. By analyzing the data they collect, these machines could adapt to the preferences of the users, providing a more intuitive and efficient cooking experience over time.

In conclusion, the future of industrial waffle makers is bright and filled with possibilities. As technology advances and consumer needs evolve, we can expect to see waffle makers that are not only more powerful and efficient but also more user-friendly and sustainable. The horizon is indeed promising for those who are eager to see what the next generation of industrial waffle makers will bring.

The evolution of the 220V industrial waffle maker has brought about a revolution in the world of culinary arts. These machines have not only transformed the way commercial kitchens operate but have also made a significant impact on the consumer market. As we stand at the brink of new technological advancements, it’s essential to reflect on the journey of these powerful appliances and anticipate what lies ahead.

These 220V waffle makers are designed with precision and efficiency in mind. They are built to withstand the rigors of high-volume production, ensuring consistent output and quality. The robust construction and durable materials used in these machines are a testament to their reliability and longevity. From stainless steel bodies to heavy-duty hinges, every aspect of these appliances is crafted to endure constant use.

The versatility of these waffle makers is another key factor that has contributed to their widespread adoption. Whether it’s for a bustling café, a busy restaurant, or a large-scale catering event, these machines can handle the demand. They come in various sizes and shapes, allowing for the creation of different types of waffles, from classic Belgian to heart-shaped and even novelty designs. This flexibility has made them a staple in many kitchens.

In terms of performance, 220V waffle makers are a cut above the rest. The higher voltage ensures a faster cooking time and a more even distribution of heat, resulting in perfectly golden, crispy waffles every time. The precise temperature control is another feature that sets these machines apart. With the ability to maintain a consistent heat setting, chefs and bakers can rely on these appliances to produce the same high-quality results batch after batch.

The energy efficiency of these waffle makers is also noteworthy. Despite their powerful performance, they are designed to minimize energy consumption. This not only saves money on utility bills but also reduces the environmental footprint. The eco-friendly aspect of these appliances is a significant advantage, especially in today’s conscious consumer market.

The catering and hospitality industry has seen a remarkable transformation thanks to the introduction of 220V industrial waffle makers. These machines have become a favorite among event planners and caterers due to their ability to quickly produce a large quantity of waffles for breakfast buffets, wedding receptions, and corporate events. The convenience and speed of these appliances have made them an indispensable tool for professionals looking to provide exceptional service.

In the consumer market, the popularity of 220V waffle makers has surged. Home bakers are raving about the ease of use and the ability to create professional-quality waffles right in their own kitchens. The excitement over these machines is evident in the numerous online reviews and social media posts. From hobbyists to seasoned bakers, there’s a collective appreciation for the convenience and delicious results these appliances deliver.

As we look to the future, the horizon for industrial waffle makers is bright. Innovations are on the horizon that promise to further elevate the capabilities of these appliances. One such innovation is the integration of smart technology. Imagine a waffle maker that can be controlled via an app, allowing users to monitor and adjust settings remotely. This would be particularly beneficial for commercial kitchens that need to manage multiple appliances simultaneously.

Another potential innovation involves the use of renewable energy sources. With the growing emphasis on sustainability, it’s not far-fetched to envision 220V waffle makers that run on solar power or other eco-friendly energy options. This would not only reduce the carbon footprint but also align with the values of environmentally conscious consumers.

In conclusion, the power of the 220V industrial waffle maker is undeniable. Its impact on the catering and hospitality industry has been transformative, and its popularity among home bakers is a testament to its versatility and convenience. As we embrace these appliances, we can also look forward to a future filled with exciting innovations that will continue to push the boundaries of what’s possible in the world of waffle making.