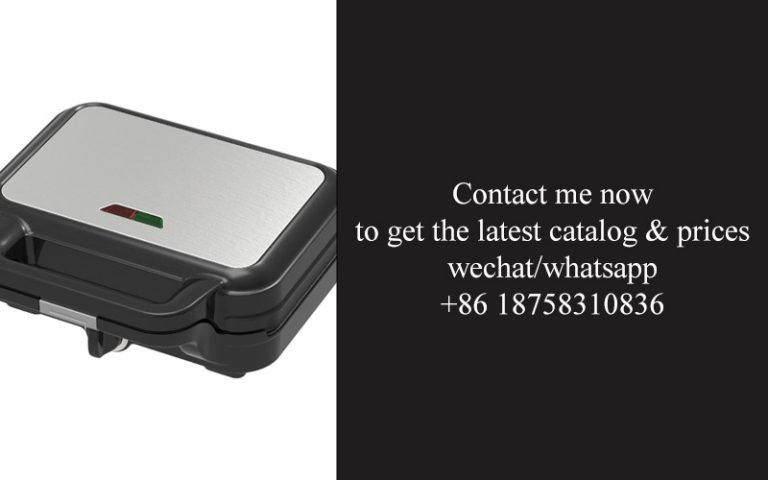

The touch Grill marketplace is experiencing robust boom due to its convenience and fitness blessings, providing massive possibilities for ODMs. contact Grill suppliers are capitalizing on the upward push in call for for healthful cooking methods, with customers looking for green and multifunctional home equipment. ODM collaborations are essential for providers to innovate, that specialize in clever temperature manage, modular designs, and

substances. via integrating era and customization, these providers can meet marketplace needs for electricity-green and customized grills, improving their competitive part inside the evolving kitchen equipment industry.

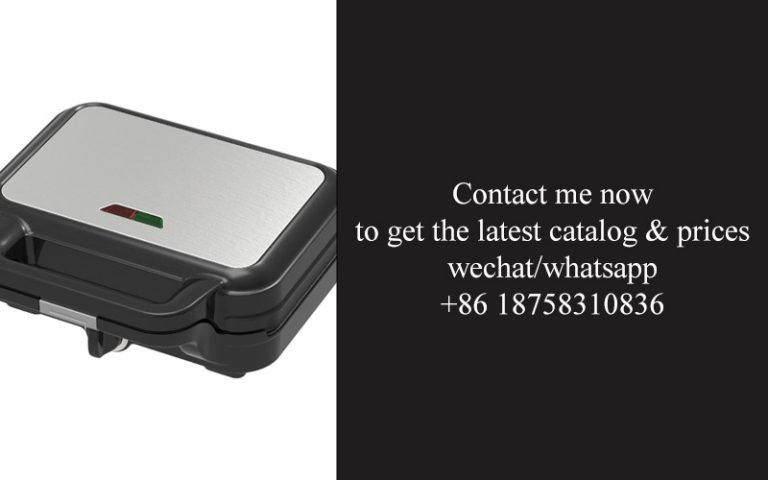

The contact Grill employer has earned a reputation for its revolutionary Bespoke touch Grill, a cooking equipment that caters to personalised wishes. this custom-designed grill gives a selection of functions, which includes high-temperature-resistant stainless-steel production for hygiene and durability, clever temperature control for specific cooking, and multi-functional modes for numerous cooking patterns. The modular design allows for clean enhancements, and the organization’s cognizance on consumer experience is clear in its anti-slip pads, detachable cooking plates, and protection lock. as the market for custom designed kitchen home equipment grows, the contact Grill corporation keeps to innovate, assembly the evolving needs of purchasers for each functionality and personalization.

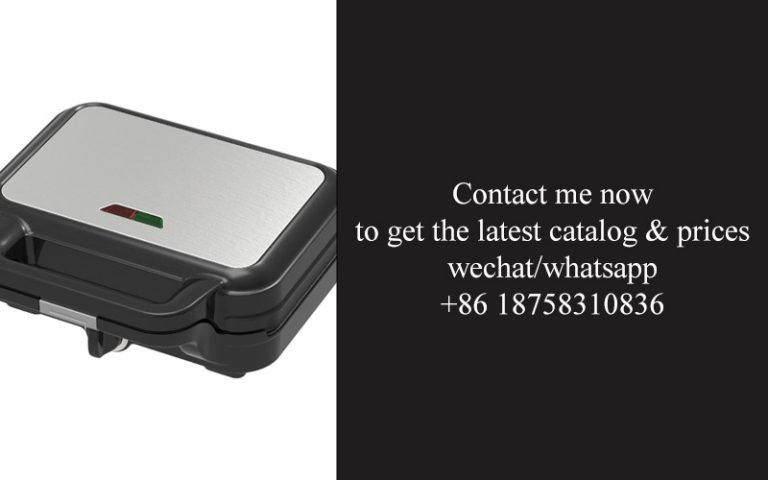

in the German kitchen appliance marketplace, producers are main with modern products and a focal point on efficiency. German Industrie Sandwich Press manufacturers, as an example, are recognized for their craftsmanship and custom solutions, providing guide, semi-automated, and fully computerized fashions. technology is at the forefront, with clever manage structures improving efficiency and person convenience. notwithstanding challenges like international opposition and environmental policies, German appliance producers are making an investment in R&D to sure performance and technology, riding market growth and keeping their competitive side.

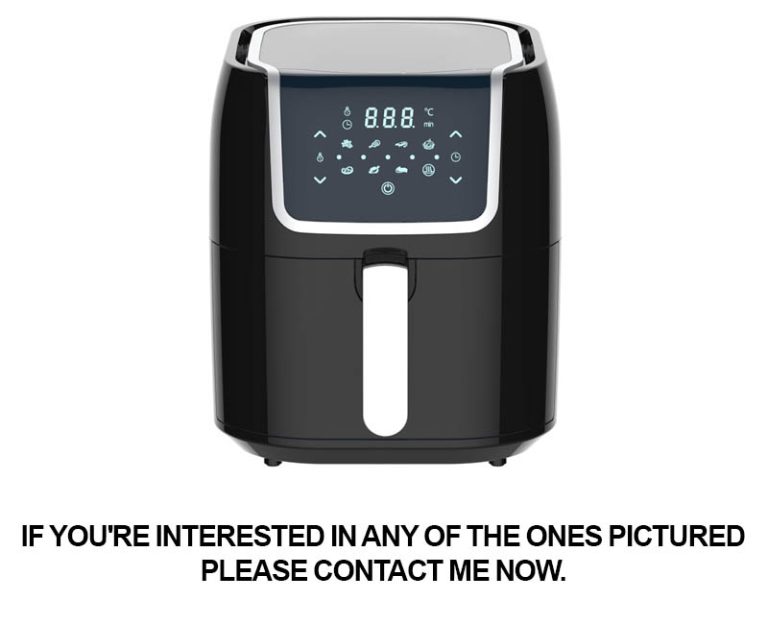

The kitchen appliance industry is witnessing a surge in innovation, pushed by means of consumers’ relentless pursuit of better existence. merchandise like professional griddles and sandwich makers are gaining great marketplace traction, supplying convenience and flexibility. these home equipment, prepared with non-stick coatings, excessive-temperature-resistant substances, and clever temperature controls, aren’t most effective simplifying cooking strategies but additionally aligning with health and environmental issues. The marketplace for expert kitchen home equipment, consisting of those modern gadgets, is predicted to grow at a strong tempo, fueled with the aid of rising fitness cognizance, the catering enterprise’s demand for performance, and the growth of e-trade channels. however, challenges including satisfactory expectancies, environmental rules, and severe opposition necessitate continuous innovation and strategic positioning within the market.

The EAC Sandwich Maker manufacturing facility, a marketplace chief in the appliance enterprise, has capitalized on the developing demand for convenience in present day life. With a focal point on innovation and market trends, the manufacturing unit produces a number sandwich makers that cater to various purchaser desires. Their merchandise, known for his or her sleek layout and user-pleasant capabilities, have gained sizable reputation inside the metropolis. The EAC Sandwich Maker factory’s commitment to fine and efficiency has made it a cross-to choice for the ones looking for a trouble-unfastened cooking revel in.

inside the ever-evolving kitchen appliance marketplace, heavy-responsibility toastie machines have emerge as a fave among baking fanatics and meals service professionals because of their robustness and efficiency. these home equipment cater to each home kitchens and business settings, offering short or even toasting for a selection of breads and baked items. With a developing demand for short and handy appliances, heavy-responsibility toastie machines are gaining prominence inside the eu and American markets. Their sturdiness, blended with technological advancements like smart controls and fitness-conscious features, positions them as a promising segment in the kitchen home equipment enterprise.

the eu and American kitchen equipment market is experiencing a transformative shift thru the Import Substitution strategy. nearby groups are fostering innovation through reducing reliance on imports, investing in R&D, and upgrading product traces to satisfy numerous purchaser desires. This method, backed by using authorities help and coverage incentives, has spurred technological breakthroughs, main to extra competitive and shrewd kitchen home equipment. The collaboration alongside the deliver chain and the emergence of niche markets like clever and

home equipment are further using the industry’s boom and innovation.

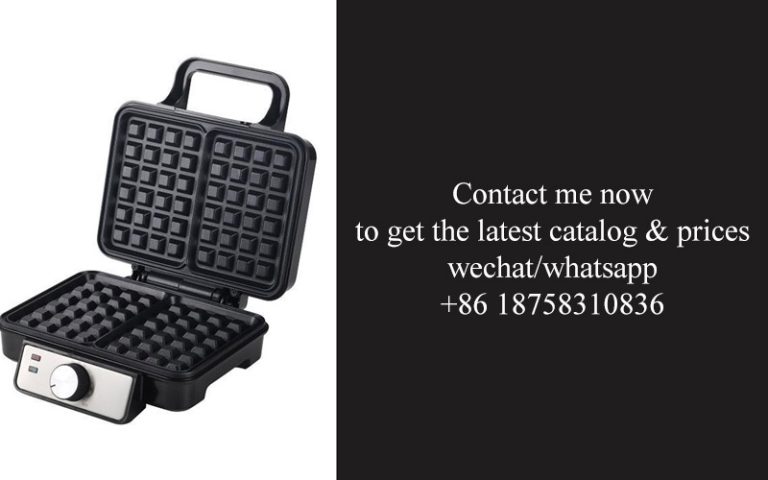

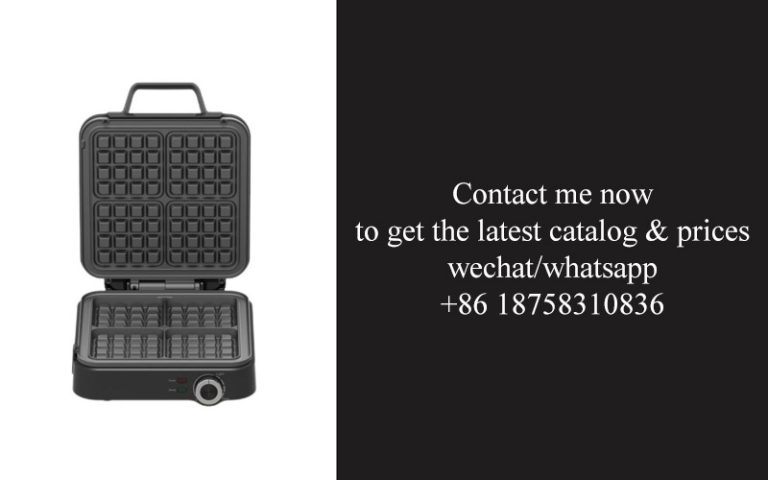

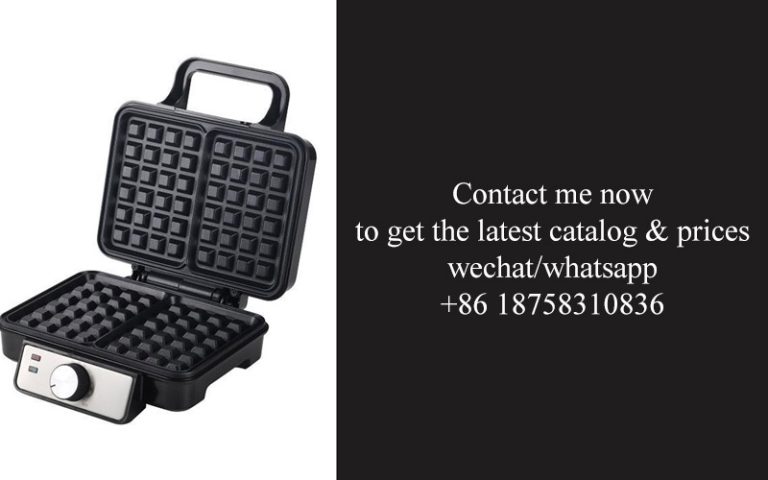

continuous operation waffle iron plant life are thriving because of their high performance and numerous functions, catering to both family and industrial needs. those centers, frequently strategically located in well-prepared enterprise parks, make use of advanced manufacturing strains and strict first-class manage systems. With abilties from raw fabric procurement to very last product trying out, those plants are equipped to supply

waffle irons. Their emphasis on automation, shrewd design, and strength-green technology ensures green manufacturing and reliability. The result is a huge variety of waffle irons with features like smart temperature control and automated flipping, assembly modern client needs for convenience and fitness.

With the surge in healthful life-style tendencies, the kitchen equipment market, specifically for strong aluminum waffle iron molds, is expanding rapidly. OEM customization is a key factor riding this boom, permitting producers to tailor merchandise to satisfy various marketplace and emblem needs. Customization complements product competitiveness, as it permits progressive design and quick edition to marketplace remarks. but, challenges which includes better manufacturing costs and the need for strong R&D and excellent control have to be addressed. in spite of these, the ability for efficiency and sturdiness in custom designed waffle irons is sizable, positioning OEM collaboration as a vital approach for manufacturers within the marketplace.

Hydraulic press production era is gaining prominence in China’s kitchen equipment quarter, supplying excessive efficiency and precision. This approach is important for enhancing product excellent and lowering power consumption. With its packages starting from variety hoods and cooktop panels to custom additives and smart appliance integration, hydraulic press generation is using innovation in kitchen appliances. in spite of challenges which include excessive technical boundaries and value issues, its capacity to create lighter, stronger, and extra environmentally pleasant merchandise is shaping the industry’s future.