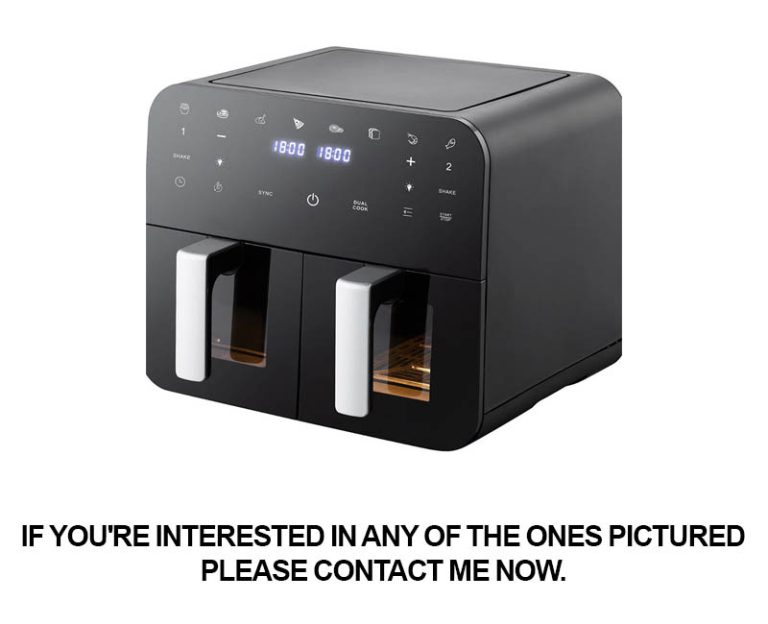

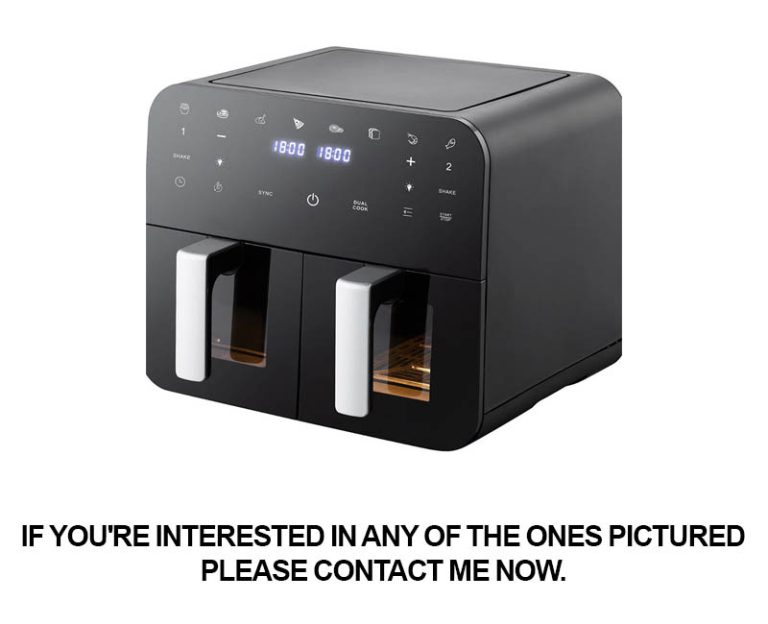

The air fryer market’s explosive growth has highlighted the crucial role of Amazon FBA suppliers for these appliances. These suppliers ensure streamlined logistics, inventory management, and quality control, allowing manufacturers to focus on innovation. By leveraging Amazon’s vast customer base and global reach, these suppliers provide manufacturers with a cost-effective and efficient way to distribute their air fryers. Their strategic partnerships offer access to data-driven insights, market trends, and scalable operations, ultimately driving the success and expansion of air fryer brands on the Amazon platform.

The kitchenware industry is undergoing a transformative shift, driven by a fusion of innovation and quality. BSCI audited factories are leading the charge in producing high-quality, ethically made products. These factories are not only committed to rigorous social and environmental standards but are also at the forefront of integrating cutting-edge technology into appliances. From smart kitchen scales that connect to smartphones to energy-efficient cookware, these advancements ensure not only convenience but also healthier and more efficient cooking experiences. The integration of technology with cooking appliances is revolutionizing the way we interact with our kitchens, making the process more intuitive and enjoyable.

In a world where the kitchen transcends cooking, our Walmart-approved small appliance supplier stands out for its innovative and aesthetically pleasing features. This supplier’s appliances seamlessly blend cutting-edge technology with modern design, offering features that streamline cooking tasks and enhance the culinary experience. From energy-efficient induction cooktops to multifunctional countertop ovens and smart appliances with intuitive interfaces, their product range caters to both convenience and style. With a focus on user-friendly design, safety, and sustainability, this supplier redefines the kitchen as a space for creativity and comfort, where cooking is not just a task but an enjoyable and efficient process.

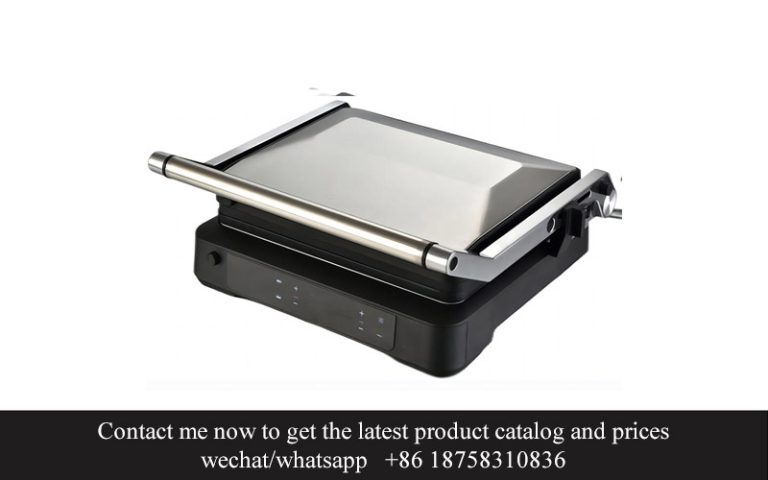

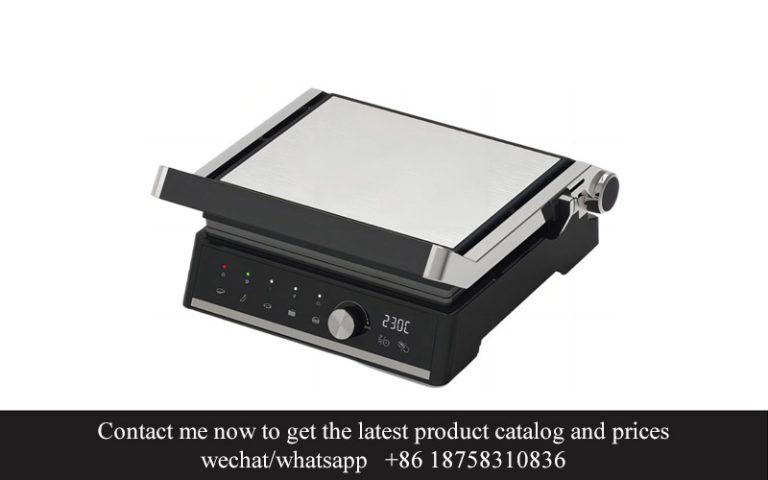

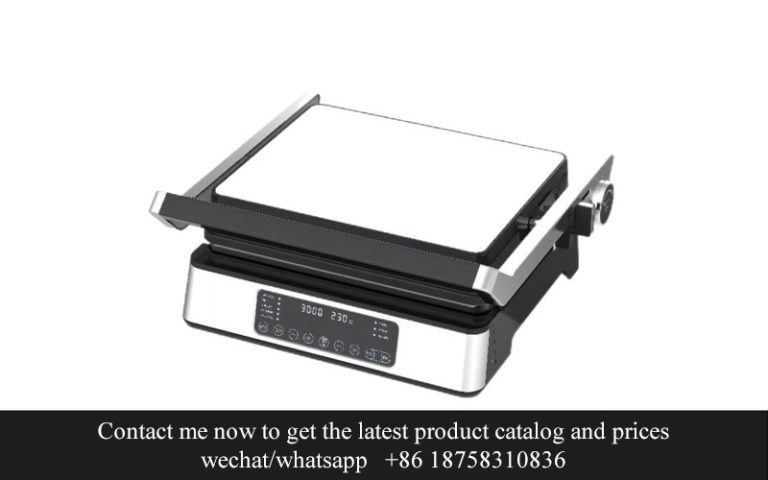

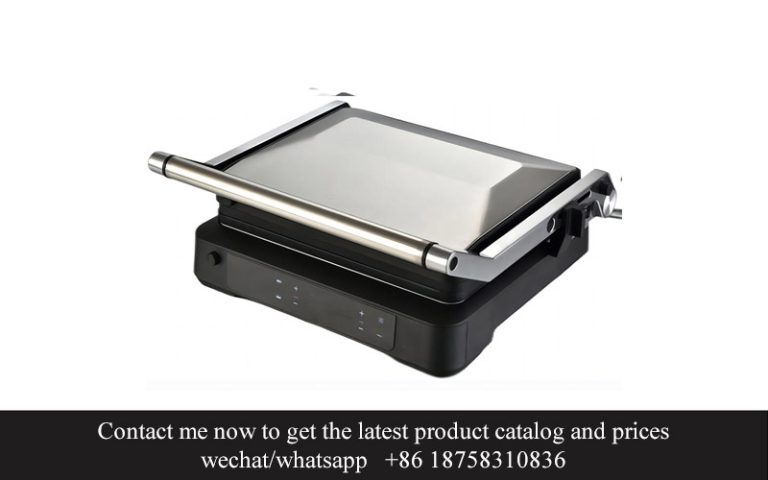

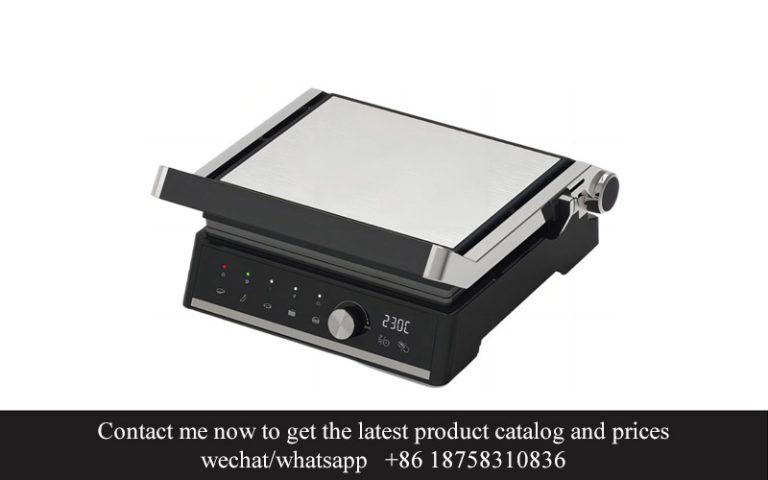

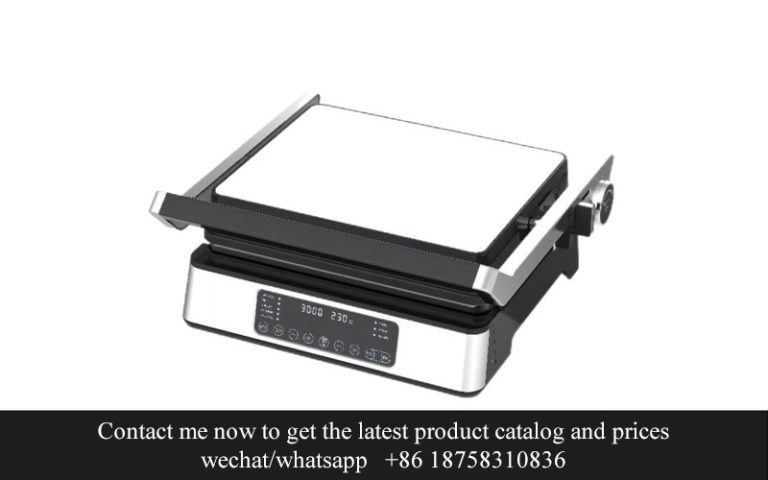

In the dynamic world of culinary appliances, the contact grill has emerged as a beloved kitchen staple. A reliable contact grill not only enhances cooking efficiency but also brings restaurant-quality results to home cooking. When selecting the perfect contact grill, it’s crucial to consider the manufacturer’s reputation and a robust 3-year warranty, which reflects confidence in the product’s quality and durability. Renowned manufacturers are known for their innovative designs, superior craftsmanship, and extensive range of products. With features like even heat distribution, non-stick coatings, and safety features, a contact grill can transform your cooking experience. By investing in a high-quality, well-reputed brand, you ensure long-term satisfaction and peace of mind.

The import substitution program is reshaping the kitchen appliances market, presenting a unique opportunity for local suppliers to redefine their role. As manufacturers adapt to evolving consumer preferences, they’re integrating advanced technology to produce high-quality, efficient, and sustainable appliances. Local suppliers are at the forefront of this transformation, leveraging their proximity to markets and understanding of local needs to develop innovative products. By fostering strategic partnerships, investing in R&D, and embracing eco-friendly practices, these suppliers are not only reducing reliance on imports but also driving innovation and economic growth within their regions.

To find a reliable air fryer factory, it’s crucial to conduct thorough market research and evaluate factory credentials. Understand the air fryer industry’s growth, key segments, and consumer trends. Look for factories with certifications, industry awards, and experience. Assess their technological capabilities, quality control processes, and supply chain. Seek recommendations and reviews, inspect factory facilities, and evaluate their product range and innovation. Analyze industry reports, focusing on market dynamics and competitor strategies. Assess communication and customer service, negotiate terms for sample orders, and consider the factory’s potential for future innovation. Finally, ensure the partnership aligns with your long-term vision and has a solid foundation for growth and reliability.

The high capacity air fryer factory has seen a remarkable ascent, achieving a 20k/month revenue milestone, thanks to the soaring demand for the appliance. Its convenience and health benefits have made it a staple in modern kitchens, particularly in urban areas where time-efficient cooking is crucial. This factory’s innovative approach to air fryer production, focusing on efficiency and quality, has allowed it to meet the growing market needs. As cooking technology evolves, the factory continues to push boundaries, offering not just a healthier alternative to traditional frying but also a range of smart features that cater to the evolving demands of city dwellers seeking quick, nutritious meals.

The automated air fryer assembly line has revolutionized the appliance market, transforming the air fryer from a niche product to a kitchen staple. This innovative assembly process, utilizing robotics and advanced machinery, ensures precision, efficiency, and high-quality production. The air fryer, once a symbol of healthier cooking, now offers consumers a versatile, convenient cooking option that retains the delicious taste and texture of fried foods with significantly less oil. As technology continues to advance, the air fryer’s role in modern cooking is expanding, making it an indispensable tool in the quest for quicker, healthier, and more enjoyable cooking experiences.

The rise of the OEM air fryer, enhanced through mold making services, has sparked a revolution in home cooking. These innovative appliances cater to the growing demand for health-conscious, efficient cooking methods. By utilizing custom molds, brands can offer a diverse range of air fryers with unique designs and features, appealing to a wide audience. This technological advancement not only allows for personalized and aesthetically pleasing products but also drives innovation in cooking appliance design, ultimately improving the cooking experience and consumer satisfaction.

In the heart of the culinary revolution, integrated circuit board (ICB) factories are the unsung architects behind the smart kitchen appliances transforming our cooking experiences. These factories, with their advanced technology and meticulous craftsmanship, produce ICBs that power appliances from ovens to refrigerators. These tiny yet powerful circuits enable precision cooking, energy efficiency, and connectivity, turning everyday tasks into seamless experiences. As consumer demands evolve, ICB factories are innovating to create more efficient, personalized, and intuitive kitchen appliances, revolutionizing the way we cook and live.