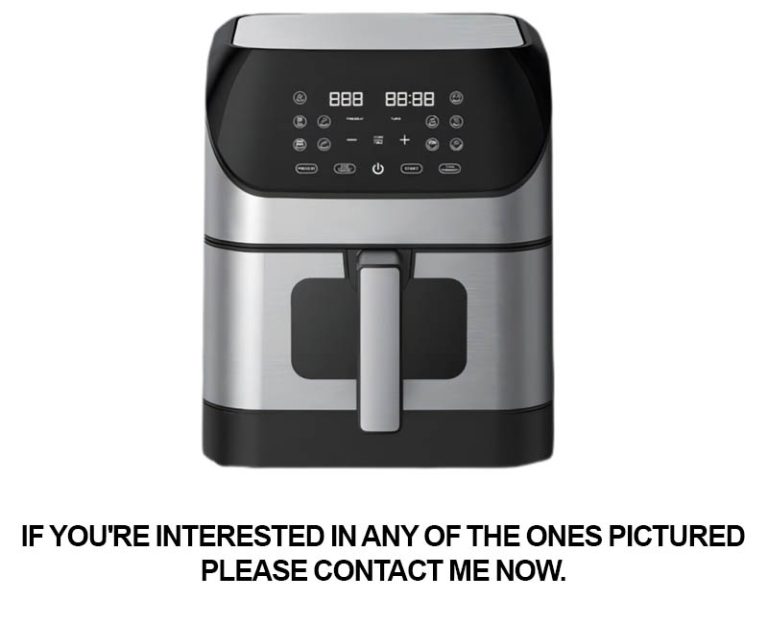

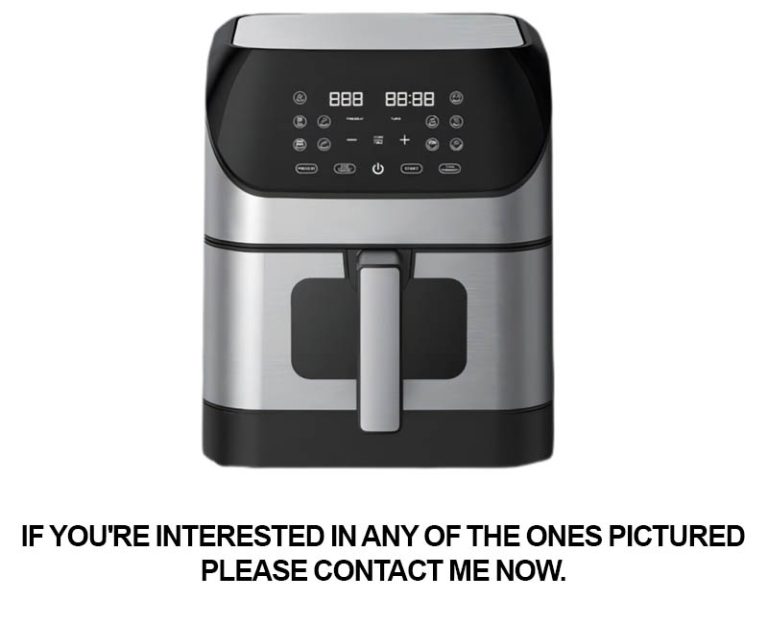

In the ever-growing kitchen appliance market, the FOB Ningbo air fryer supplier has become a leading force, revolutionizing cooking with its innovative air fryers. These appliances, crafted in Ningbo, offer a healthier alternative to traditional frying, thanks to their ability to cook with minimal oil. The city’s strategic location and advanced infrastructure have enabled these suppliers to produce high-quality, energy-efficient air fryers that cater to a global audience. These compact and versatile devices have transformed cooking, allowing for a variety of recipes with minimal cleanup. As the demand for healthier, convenient cooking options continues to rise, FOB Ningbo air fryer suppliers are poised to shape the future of kitchen appliances.

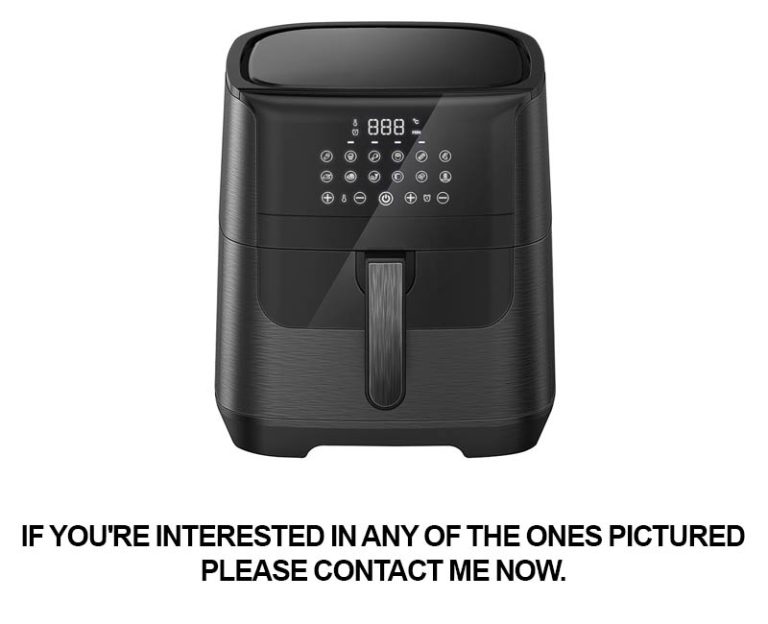

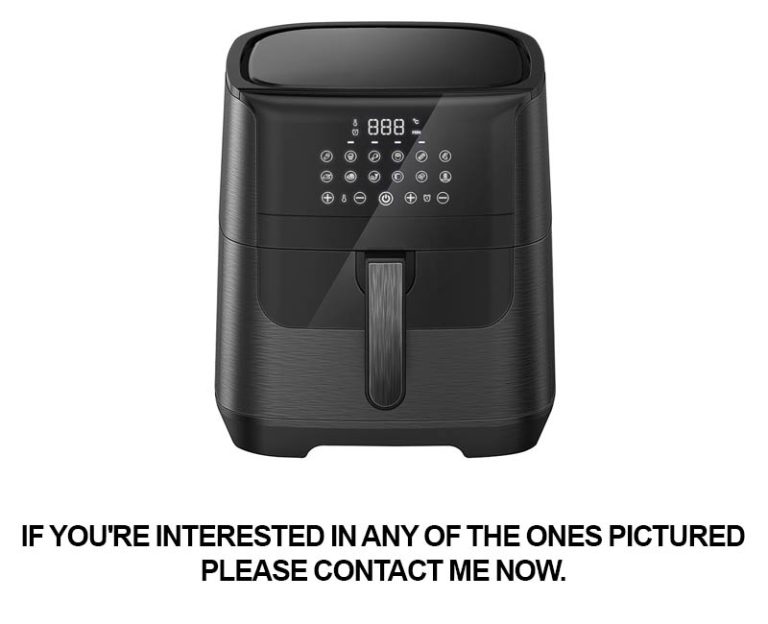

In the ever-evolving kitchen appliance industry, the 2200W powerhouse stands out as a beacon of innovation, offering enhanced cooking capabilities and efficiency. These high-wattage appliances, such as ovens and cooktops, are not only designed to perform tasks like boiling and searing at lightning speed but also to do so with precision and safety. The CE-EMC compliant nature of these devices ensures they meet stringent European standards for electromagnetic compatibility and electrical safety, making them reliable and user-friendly. This combination of power, performance, and safety is transforming the way we approach cooking, with kitchen appliances now acting as game-changers in our culinary endeavors.

In the heart of Moscow, the air fryer manufacturing industry has experienced a remarkable surge, with local manufacturers revolutionizing the global cooking landscape. The Moscow air fryer manufacturer has become a trailblazer, offering innovative, energy-efficient, and health-conscious appliances that cater to a wide range of culinary preferences. These air fryers, once a niche product, are now staples in modern kitchens worldwide, thanks to their ability to deliver crispy, low-fat meals at the touch of a button. With a commitment to smart technology, safety, and eco-friendliness, the Moscow air fryer manufacturer has earned international acclaim, propelling the air fryer into the forefront of the culinary revolution.

The commercial air fryer industry is witnessing a remarkable surge, driven by the demand for healthier cooking alternatives. A leading commercial air fryer factory has embraced this trend, innovating with efficient designs and smart technology. These air fryers, once confined to niche markets, have now become staples in various kitchens, from restaurants to catering services. Their ability to produce crispy, low-oil foods has not only captured health-conscious consumers’ attention but also delighted chefs seeking lighter yet satisfying dishes. This technological advancement in kitchen appliances is transforming cooking practices, promoting healthier eating habits, and offering businesses a competitive edge.

The restaurant-grade air fryer factory is at the forefront of culinary innovation, producing appliances that are redefining home cooking. These air fryers, once exclusive to professional kitchens, now offer health-conscious cooks the ability to achieve restaurant-quality cooking at home. The factory’s meticulous processes, using high-quality materials and advanced technology, ensure durability and efficiency. With their ability to replicate the crispy textures of deep-fried foods with minimal oil, these air fryers have become a game-changer in the kitchen appliance market, embraced for their versatility, health benefits, and convenience.

The Heavy Duty Sandwich Press Factory is at the forefront of crafting the perfect sandwich, offering appliances that ensure consistent cooking and a golden-brown crust. Their presses, known for their robust construction and innovative features, are designed to elevate the art of sandwich making. With adjustable pressure and non-stick surfaces, these heavy-duty presses guarantee a sure-to-please cooking experience. Their unique features, such as ergonomic handles and removable drip trays, make cooking a breeze, while their sleek designs complement any kitchen. The factory’s commitment to quality and safety is evident in their durable products, making them a top choice for both home cooks and professional chefs.

The continuous operation sandwich grill plant represents a technological breakthrough in the foodservice industry, offering non-stop, high-volume cooking capabilities. These innovative grills are designed to maintain consistent cooking temperatures and efficiently process a variety of ingredients, from bread to fillings, ensuring high-quality sandwiches are produced at a rapid pace. The integration of advanced technology within these plants, such as automated feeding systems and energy-efficient heating elements, has transformed the traditional sandwich-making process, making it both faster and more reliable. As the industry evolves, continuous operation sandwich grill plants are becoming integral to meeting the demands of modern consumers seeking quick, convenient, and delicious meals.

In-house mold making has revolutionized the grill manufacturing industry, empowering manufacturers to produce custom components with precision and speed. This shift has led to innovative grill designs, enhanced cooking experiences, and greater control over quality. By integrating advanced technology such as CAD/CAM software and 3D printing, companies are able to create intricate molds that drive product differentiation and cater to evolving consumer preferences. This in-house approach not only streamlines the production process but also fosters a culture of innovation, ensuring that grills remain at the forefront of modern cooking technology.

The UL-certified commercial sandwich maker OEM has revolutionized the industry with its advanced features and innovative design. This state-of-the-art sandwich maker boasts a range of capabilities, including precise temperature control, programmable settings, and efficient cooking times, making it a game-changer for commercial kitchens. Its durable construction and user-friendly interface ensure seamless integration into any busy environment, enhancing operational efficiency and customer satisfaction. With its commitment to safety and sustainability, this sandwich maker stands out as a reliable and eco-friendly solution for any foodservice establishment.

Integrated metal stamping for sandwich plates has revolutionized the kitchen appliance industry, providing manufacturers with a powerful tool for creating durable, precision-engineered components. This technology has not only enhanced the aesthetics and functionality of kitchenware but also streamlined production processes, reducing costs and waste. The versatility of integrated metal stamping allows for intricate designs and customizations, making it an indispensable asset for modern appliance manufacturing. As technology advances, the potential for further innovation in sandwich plate metal stamping promises to continue reshaping the landscape of kitchen appliances, offering manufacturers new ways to cater to consumer demands for both style and performance.