Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

With the worldwide consumers’ pursuit of handy and various culinary delights, the kitchen equipment market is experiencing a surge in improvement. mainly inside the ecu and American areas, waffle makers have gained enormous reputation amongst clients due to their precise texture and rich layout of shapes. this article will delve into the developing call for for non-stop operation waffle makers in the eu and American markets, and discover the relevant technological innovations and product traits, aiming to offer precious insights for the kitchen equipment industry in China.

continuous operating waffle iron production bases are normally positioned in without problems on hand business parks with nicely-developed infrastructure. these bases cowl a big area and are equipped with superior manufacturing traces and stringent best manipulate structures. The production system tiers from uncooked cloth procurement, component processing, meeting, to finished product checking out, forming a complete manufacturing line. research and improvement centers are also established within the bases, devoted to the improvement of latest merchandise and technological upgrades of current ones. additionally, production bases area emphasis on environmental protection and power efficiency, using clean manufacturing technologies and gadget to reduce environmental effect at some stage in the manufacturing procedure.

In terms of manufacturing device, non-stop working waffle iron production bases are prepared with a couple of excessive-automation production lines. those traces are capable of reaching excessive-velocity and green manufacturing to fulfill the large marketplace demand for waffle irons. The gadget consists of, however isn’t always constrained to, unique reducing machines, welding robots, portray traces, and automatic inspection gadget. A expert crew is responsible for the operation and renovation of these device, ensuring the stableness of the manufacturing strains and the reliability of the goods.

concerning great control, the bases have implemented strict satisfactory management systems, with exact inspection standards at each stage from raw materials to finished products. satisfactory trying out system consists of high-precision scales, hardness gauges, spectrometers, and different gadgets that may display product exceptional in real-time. The bases also conduct regular quality attention training for personnel to ensure that each worker strictly adheres to operational techniques, thereby guaranteeing the satisfactory of the waffle irons.

to conform to the different market needs, the manufacturing bases provide a rich sort of products, together with waffle irons of different models and features, which are not handiest suitable for household use however also widely carried out in the catering enterprise, resorts, and commercial baking. via closely participating with clients, the bases recognize market needs and continuously launch new merchandise to meet the personalized desires of different consumer groups.

In terms of supply chain control, the bases have installed long-term and solid cooperative relationships with a couple of providers to make sure the high-quality and stability of raw fabric deliver. moreover, the bases also pay attention to logistics distribution, cooperating with more than one logistics groups to make sure that products may be introduced to customers quick and appropriately.

In phrases of skills cultivation, the bases attach significance to the ability development and profession development of personnel. through internal training and outside studies, the professional talents and complete features of employees are constantly stronger, offering a sturdy expertise assure for the continuous improvement of the bases.

In summary, the continuous running waffle iron manufacturing bases occupy a place in the kitchen appliance industry with their superior production equipment, strict satisfactory manage, various product lines, efficient supply chain management, and exquisite talent crew. as the market maintains to broaden and generation, the bases will hold to strive to improve manufacturing performance and product first-rate, supplying clients with more products and services.

non-stop operation waffle makers have emerged prominently inside the market thanks to their excessive production efficiency and solid exceptional. As consumers’ call for for breakfast meals becomes an increasing number of various and the food provider enterprise’s urgent need for brief carrier grows, the income of such gadget are showing a full-size upward fashion.

For family purchasers, with the short-paced pace of lifestyles, handy breakfast solutions are in excessive call for. non-stop operation waffle makers can fast produce a selection of waffles, fulfilling the family customers’ pursuit of various breakfasts. moreover, with the recognition of the healthful consuming concept, low-sugar, low-fat waffle products are more welcomed within the marketplace, riding the demand for non-stop operation waffle makers.

inside the meals carrier industry, in particular in speedy-meals and café institutions, non-stop operation waffle makers have grow to be a key device for improving provider pace due to their high performance. in the course of peak hours, a unmarried manually operated waffle maker often struggles to satisfy the demands of a massive range of customers, however non-stop operation waffle makers can gain automatic batch manufacturing, efficaciously shortening patron wait times and improving patron satisfaction.

because the food processing industry maintains to develop, more and more food businesses are specializing in production line automation. non-stop operation waffle makers aren’t handiest suitable for the meals provider enterprise however additionally for small-scale production in meals processing organizations, assembly the dual needs for product first-class and efficiency. therefore, inside the discipline of meals processing, the utility of continuous operation waffle makers is also expanding.

pushed by way of e-trade structures, purchasers’ demand for personalised and customized products is continuously growing, which additionally brings new marketplace opportunities for non-stop operation waffle makers. producers can adjust molds and formulas to cater to one-of-a-kind customers’ flavor alternatives, for this reason securing an area in the extreme market opposition.

In summary, the developing call for for continuous operation waffle makers inside the market is attributed to their green, handy, and various functions, as well as their excessive alignment with consumer life and developments within the meals provider enterprise. looking ahead, with the continuous development of generation and further marketplace enlargement, this product class is anticipated to hold its growth momentum.

The continuous operation waffle iron has stood out in the kitchen equipment marketplace in current years, with its call for displaying a sizeable growth fashion. clients’ pursuit of convenience and range in breakfast has brought new power to this conventional delicacy in modern kitchens. With its twin position in both home and commercial use, this product reveals extensive software in various scenarios inclusive of catering, baking, and families. furthermore, with the recognition of the healthy eating idea, waffles, with their low-fats and healthy attributes, have received prefer amongst an increasing number of consumers.

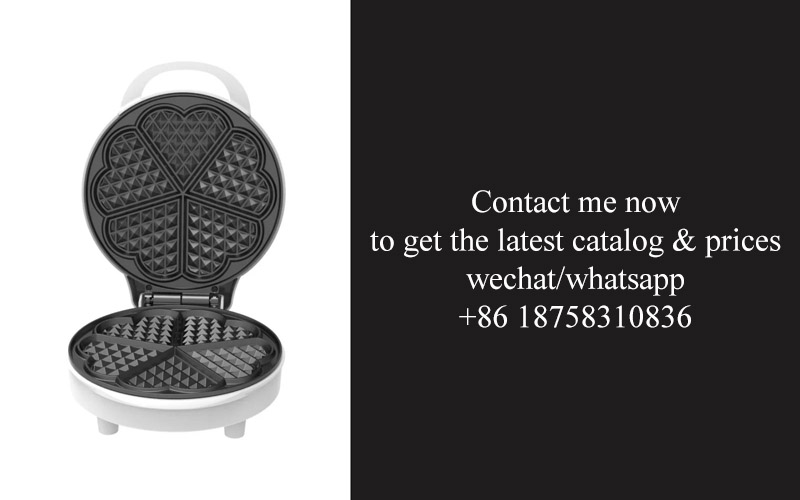

In product layout, intelligence and multifunctionality are the important thing. The ultra-modern generation of non-stop operation waffle irons integrate a couple of modern technology, such as smart temperature control and automatic flipping functions, to make sure that every baking session achieves the quality results. moreover, the system’s smooth-to-smooth design substantially complements the consumer’s preservation revel in. the choice of materials, consisting of high-temperature-resistant and non-stick coatings, no longer simplest extends the gadget’s lifespan however additionally reduces food residue, making sure food protection.

In phrases of manufacturing traces, the development in automation and intelligence has significantly progressed manufacturing performance. Modular design permits for flexible configuration of the manufacturing line in line with production scale and demand. Key components including heating elements and transmission structures have all undergone rigorous testing to make certain problem-loose continuous operation. An wise tracking device real-time monitors various parameters at some stage in the manufacturing system and at once alarms in case of any anomalies, making sure production safety. moreover, the layout of the manufacturing line takes environmental issues under consideration, the usage of energy-saving substances and approaches to lessen power intake and limit environmental impact.

to fulfill the numerous needs of users, the continuous operation waffle iron production line also offers a number custom designed merchandise. From special sizes of molds to customized pattern customization, customers can select the most appropriate waffle iron in keeping with their tastes and logo photo. In phrases of services, a one-prevent carrier is furnished from pre-income session, system installation, to after-sales maintenance, ensuring complete guide for customers for the duration of their use.

With the increasing pursuit of satisfactory existence through customers and their emphasis on healthy ingesting, the marketplace prospect for non-stop operation waffle irons is promising. thru technological innovation and product function optimization, green manufacturing traces no longer handiest meet present day marketplace demands however also lay a strong foundation for destiny marketplace development.