Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

in the incredibly competitive kitchen appliance market, decreasing costs and improving performance are the core desires for manufacturers. this newsletter will delve into how to obtain a 30% cost discount for customized touch grills via progressive design and price optimization techniques, and examine the information support and industry insights in the back of it.

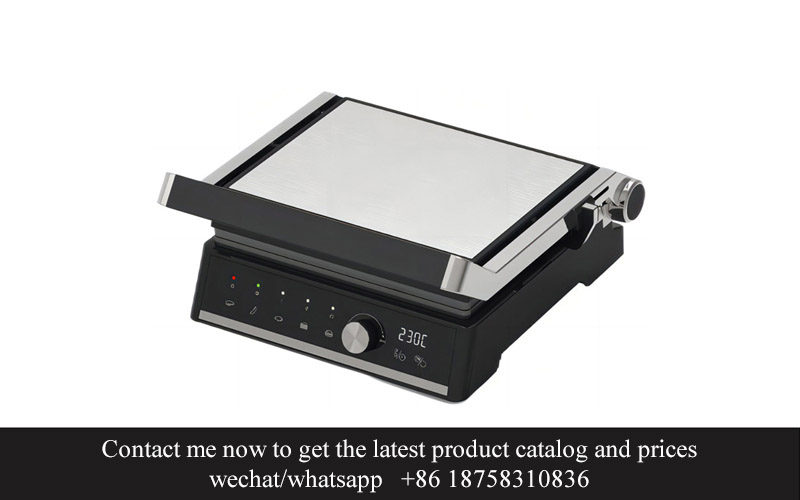

The OEM marketplace for customized touch grills is experiencing a series of vast traits. firstly, the developing emphasis on healthy consuming via purchasers has pushed the demand for smokeless and multi-functional cooking home equipment, directly influencing the layout and functionality of grills. Secondly, the upward thrust of smart homes has made the intelligence of grills feasible, with features like integrated temperature manipulate and smart cooking packages becoming the brand new favorites in the enterprise. moreover, the deep-seated environmental awareness is prompting manufacturers to choose environmentally friendly and recyclable materials of their material selections.

With the increasing call for for personalization, custom designed services are gaining popularity in the OEM marketplace for touch grills. customers are not simplest involved about the basic capabilities of the product however also are seeking customized customization in terms of appearance design, size, and additional features. This fashion requires producers to have robust R&D capabilities and bendy manufacturing strains to speedy respond to the diverse marketplace demands.

Technological innovation is a key component driving the improvement of the OEM market for touch grills. New heating technology, extra green temperature control algorithms, and wise cooking structures are constantly rising, enhancing the product’s value-overall performance. furthermore, with the improvement of the net of factors, grills can connect to telephone apps for remote manipulate and statistics analysis, supplying users with a extra handy experience.

market analysis suggests that the demand for customized contact grills in the excessive-stop marketplace is growing, at the same time as the mid-to-low-stop marketplace is looking for breakthroughs in a balance between cost-overall performance and realistic capability. producers need to regulate their product techniques in line with one-of-a-kind market positioning to satisfy the desires of various purchasers.

in the face of an increasing number of fierce opposition, value manipulate has turn out to be a key issue for the survival and development of firms. by way of optimizing deliver chain management, improving production efficiency, and adopting advanced production technologies, manufacturers are predicted to efficiently reduce expenses. additionally, setting up lengthy-term partnerships with suppliers to reap extra favorable raw fabric expenses is likewise an important approach of cost reduction.

In precis, the custom designed touch grill OEM marketplace is characterized by assorted patron call for, non-stop technological innovation, intensifying marketplace opposition, and value manipulate being a key issue. manufacturers need to preserve up with market trends, enhance product competitiveness, and occupy a favorable position in the acute marketplace opposition.

the subsequent is the translation of the content material into English:

in the kitchen equipment enterprise, customized contact baking plates for OEM have become a major warm spot. corporations are improving product marketplace competitiveness thru innovative design, whilst also achieving full-size cost manage effects. the following will discuss several key points concerning modern design and cost optimization techniques.

Modular design enhances efficiency and flexibilityModular design has turn out to be a chief fashion within the kitchen equipment industry in latest years. by way of modularizing the principle practical modules of the contact baking plate, companies can quickly adapt to specific patron wishes, at the same time as also simplifying the manufacturing procedure. This layout makes the producing and protection of the baking plate greater green, reducing extra fees associated with customization. moreover, modularization additionally allows rapid generation based on marketplace comments, pleasant customers’ pursuit of customized products.

material Innovation Reduces expensesmaterial prices account for a significant share in kitchen equipment merchandise, making material innovation important for cost optimization. a few organizations have began to apply new light-weight and excessive-electricity substances, inclusive of aluminum alloy rather than traditional stainless-steel, which not most effective lightens the product weight but also reduces cloth charges. on the same time, by means of optimizing the material structure, inclusive of the use of multi-layer composite substances, it is viable to obtain fee financial savings even as ensuring product performance.

intelligent era Improves power efficiencyThe utility of clever technology is an effective way to lessen strength consumption and optimize charges. The touch baking plate, included with an wise manipulate machine, can robotically adjust temperature and time based on cooking wishes, avoiding electricity waste. similarly, via faraway tracking and statistics analysis, companies can higher control the production method, lowering power intake, and therefore lowering typical running fees.

four. supply Chain Integration and Lean controlvalue optimization isn’t handiest about product layout innovation however also consists of the optimization of supply chain control and production procedures. by using setting up near relationships with suppliers, agencies can attain greater favorable raw material costs at the same time as making sure the stability and responsiveness of the supply chain. Lean control reduces fees with the aid of eliminating waste and improving production performance, such as optimizing manufacturing techniques to reduce downtime and increase the utilization price of manufacturing strains.

thru these strategies, companies attain powerful fee manage while innovating in design. This not simplest complements product market competitiveness however additionally lays a strong basis for the sustainable improvement of the agency.

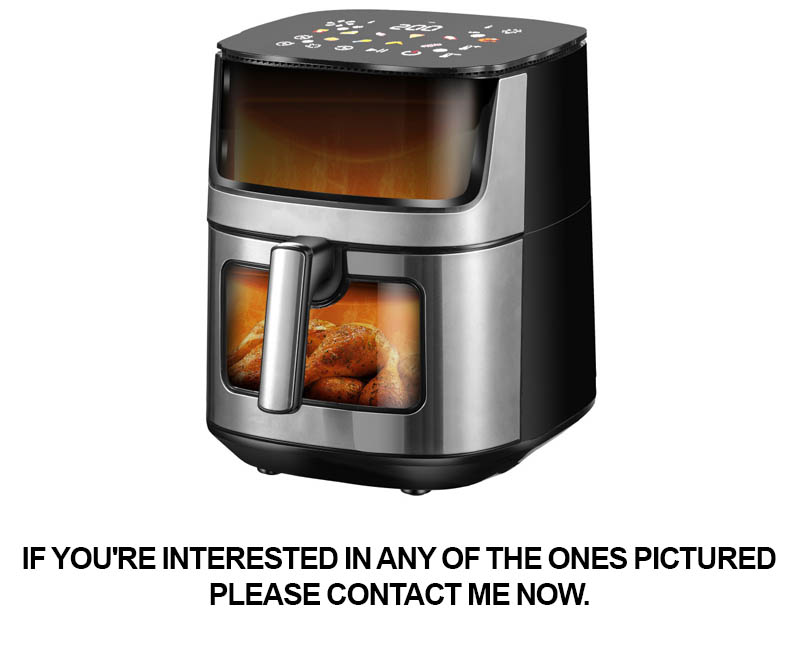

in the kitchen equipment industry, the OEM region for custom designed touch baking plates is undergoing a cost revolution. via in-depth facts evaluation and enterprise practice, we have determined that via a chain of modern designs and fee optimization techniques, organizations can obtain fee reductions of up to 30%. beneath are the facts assist and industry insights behind this success.

data One: fabric Innovation and Substitutionthrough in-depth research on baking plate substances, we’ve located that the use of new composite substances to replace traditional substances can acquire cost financial savings of approximately 20% even as maintaining product overall performance. as an instance, the usage of light-weight alloys as opposed to stainless-steel now not only reduces the weight of the baking plate however also lowers the producing value.

statistics : production system Optimizationinside the manufacturing technique, the creation of automatic production lines has reduced labor fees. on the equal time, optimizing the production method has shortened the manufacturing cycle and decreased stock prices. information shows that after the implementation of automation, manufacturing efficiency has elevated by 30%, and inventory charges have decreased via 15%.

statistics 3: supply Chain Integrationthrough the integration of the deliver chain, high-quality management has been done inside the procurement of raw materials and logistics distribution. via setting up long-term cooperative relationships with providers, more favorable procurement costs are obtained, and logistics routes are optimized, reducing transportation fees. information display that after deliver chain integration, raw fabric fees have decreased by 10%, and logistics costs have decreased by 5%.

facts four: Product design Optimizationthroughout the product design section, via simulation trying out and person remarks, the shape, thickness, and different parameters of the baking plate are optimized to reduce fabric waste. on the equal time, the product structure is simplified, decreasing meeting issue and value. according to information evaluation, after product layout optimization, material utilization has multiplied with the aid of five%, and assembly costs have decreased via eight%.

facts 5: service model InnovationIn terms of after-sales service, the status quo of a faraway prognosis gadget has decreased the number of on-web page upkeep and fees. in addition, the creation of recent provider models which includes change-in and leasing has elevated purchaser loyalty whilst also lowering the agency’s repair expenses. consistent with the survey, after carrier model innovation, repair prices have reduced by means of 20%, and patron satisfaction has extended by means of 15%.

enterprise Insights:1. fabric innovation is the key to price reduction. companies need to constantly explore new substances and optimize product systems to reduce fabric prices.2. manufacturing method optimization is an powerful way to enhance performance and decrease prices. Automation and informatization are the traits of future manufacturing.3. deliver chain integration can obtain fee financial savings. organizations must toughen cooperation with suppliers and optimize deliver chain management.four. layout optimization can improve cloth utilization and decrease manufacturing fees. corporations have to consciousness on person enjoy and continuously optimize product layout.five. service model innovation can beautify purchaser pride whilst lowering corporate charges. corporations need to actively explore new service fashions to increase patron price.