Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the world of culinary craftsmanship, the art of making a perfect sandwich is a blend of tradition and innovation. It’s a testament to the simplicity and versatility of food, where a few ingredients can come together to create a delightful meal. As technology evolves, so does the way we prepare and enjoy our sandwiches, leading to the emergence of specialized tools like the heavy-duty sandwich press. Today, we delve into the fascinating journey of sandwich presses, exploring their evolution, the importance of heavy-duty construction, the cutting-edge factory that produces them, and the unique features that set these products apart. We’ll also examine the latest industry trends, customer success stories, and the commitment to sustainability and safety that defines the future of sandwich making.

In the world of culinary delights, the sandwich holds a special place. It’s a portable, versatile meal that can be as simple as a slice of bread with cheese and as complex as a gourmet creation with multiple layers of fillings. The art of the perfect sandwich lies not just in its ingredients, but in the balance, texture, and overall experience it provides.

The foundation of any great sandwich is the bread, a canvas upon which the flavors of the fillings can be painted. From the soft, chewy texture of sourdough to the crisp crust of a baguette, the right bread can elevate the simplest of ingredients to something extraordinary. It’s about the harmony of flavors, where the tang of the cheese complements the sweetness of the tomato, and the umami of the cured meats dances with the freshness of the lettuce.

But the bread is just one element. The choice of fillings is crucial; it’s where the sandwich becomes a reflection of personal taste and culinary creativity. Whether it’s a classic ham and cheese, a spicy Italian sub, or a hearty vegetarian masterpiece, the art of the perfect sandwich is about selecting ingredients that not only taste good together but also work well in terms of texture and temperature.

A perfect sandwich should have layers of flavors and textures that work in concert. Crunchy lettuce and fresh tomatoes add a refreshing crunch, while melted cheese provides a creamy, rich mouthfeel. The right balance of condiments, like mayonnaise, mustard, or aioli, can tie the flavors together, creating a cohesive and satisfying bite. It’s not just about the taste; it’s about the experience of taking a bite, feeling the crunch, and savoring the blend of flavors.

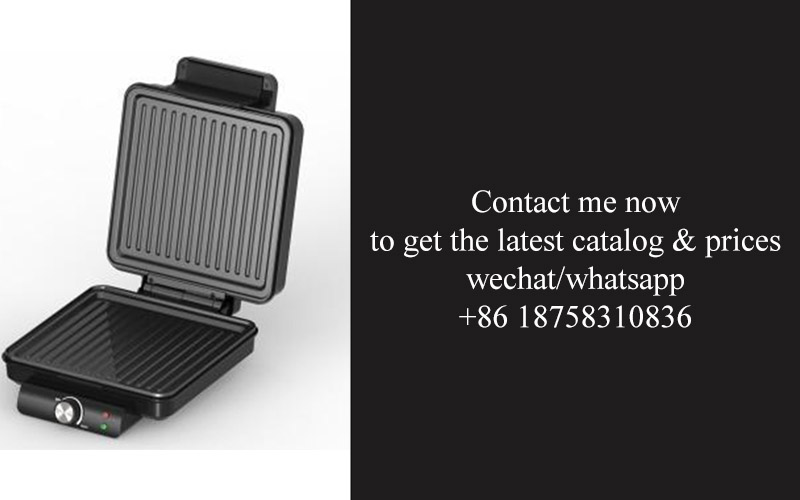

The technique of cooking the sandwich also plays a significant role in its perfection. A toasted sandwich, for instance, adds a delightful caramelization to the bread that complements the ingredients. The use of a sandwich press ensures even cooking and a golden brown crust, locking in the flavors and making the sandwich moreish. The art of pressing not only helps with even cooking but also adds a certain level of sophistication to the sandwich-making process.

The presentation of a sandwich is also a part of its artistry. A neatly arranged sandwich, with clean lines and a uniform appearance, can be as visually appealing as it is delicious. It’s not just about the look; it’s about the attention to detail that makes a sandwich feel special, whether it’s served at a bustling café or a high-end restaurant.

Moreover, the art of the perfect sandwich is not confined to the professional kitchen. Home cooks can master this craft through experimentation and practice. It’s about embracing the joy of cooking and the satisfaction of creating something that tastes as good as it looks and feels.

In a world where time is often at a premium, the sandwich remains a simple yet satisfying solution. It’s a meal that can be crafted with care or thrown together with ease, but the art of the perfect sandwich is about that moment when all the elements come together to create something transcendent. It’s about the joy of discovery, the thrill of the culinary adventure, and the simple pleasure of a well-executed sandwich.

The sandwich press, once a mere kitchen gadget, has evolved into an essential tool for crafting the perfect bite. From its humble beginnings to the sophisticated appliances of today, the journey of sandwich press technology is a testament to culinary innovation.

Once upon a time, the concept of pressing a sandwich was simple: a flat piece of metal or a heavy pan was used to flatten bread and ensure even toasting. These primitive methods lacked the precision and control that modern sandwich enthusiasts demand. As the culinary world grew more sophisticated, so too did the devices designed to press our favorite meals.

The early 20th century saw the birth of the first commercial sandwich presses. These were often simple, flat-bottomed contraptions that provided a basic level of compression to the bread, helping to create a more even and appealing sandwich. They were a step up from the old-fashioned methods, but still lacked the finesse required to produce a truly perfect sandwich.

The mid-20th century marked a significant turning point in sandwich press technology. The introduction of spring-loaded mechanisms allowed for greater control over the amount of pressure applied to the sandwich. This innovation meant that users could now achieve a consistent level of toasting and texture with each press. It was a game-changer for sandwich lovers, as the quality of the finished product improved dramatically.

As the decades rolled on, sandwich presses began to incorporate various features that catered to different preferences. The adjustable heat settings allowed for a range of doneness levels, from a light, toasty crust to a well-done, caramelized exterior. Some models even included a non-stick surface, making it easier to clean and ensuring that the bread would not stick to the press.

In the late 20th century, sandwich presses became more than just kitchen tools; they became a symbol of culinary artistry. The introduction of unique shapes and sizes, such as the classic square, rectangular, and even heart-shaped presses, added an element of fun to the process of making a sandwich. These new designs not only enhanced the visual appeal of the final product but also provided additional options for creative sandwich making.

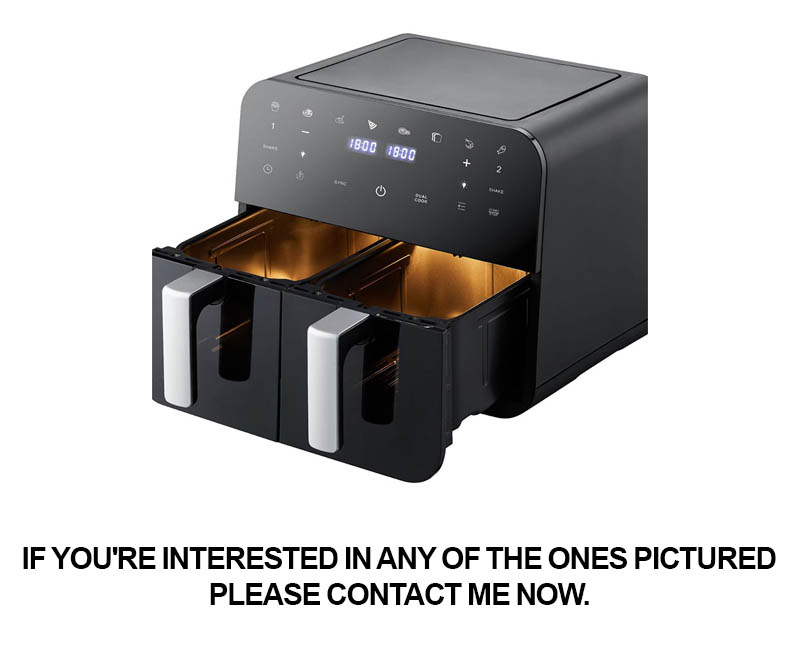

The 21st century has brought us even more advancements in sandwich press technology. Modern models now come with digital controls, allowing users to precisely set the desired temperature and cooking time. Some presses even have built-in timers and auto-shutoff features, ensuring that the sandwich is perfectly pressed and toasted every time.

Beyond the technological advancements, the evolution of sandwich press technology has also been influenced by cultural trends. The rise of gourmet sandwiches, such as the gourmet panini and the avocado toast phenomenon, has spurred the development of specialized presses that can handle a variety of bread types and fillings. These presses often have adjustable plates that can accommodate different thicknesses of bread, ensuring that every ingredient is toasted to perfection.

As sandwich presses continue to evolve, they are not only becoming more efficient and user-friendly but also more stylish and versatile. Some modern presses are designed to be as much a centerpiece on the kitchen counter as they are a tool for making sandwiches. They come in a variety of colors and materials, from classic stainless steel to sleek black ceramic, allowing users to express their personal style.

In conclusion, the evolution of sandwich press technology has transformed the way we make and enjoy sandwiches. From the simple, flat-bottomed presses of the past to the sophisticated, feature-rich appliances of today, the journey has been one of continuous improvement and innovation. As long as there are sandwiches to be made, the evolution of sandwich press technology will continue to shape the culinary landscape.

The sandwich press, a simple yet essential tool in the culinary arsenal, has seen a remarkable evolution over the years. But why does the term “heavy duty” stand out in this context? The answer lies in the durability, performance, and satisfaction it brings to sandwich enthusiasts.

In the early days, sandwich presses were often seen as a mere novelty, a gadget to add a bit of flair to the humble sandwich. They were typically lightweight, with a focus on even heat distribution to achieve that perfect golden-brown crust. However, as the popularity of the sandwich surged, so did the demand for a tool that could withstand the rigors of everyday use.

The introduction of heavy-duty sandwich presses marked a significant shift in the market. These presses were built to last, with robust frames and materials that could endure countless presses without succumbing to wear and tear. The heavy-duty construction meant that the presses could withstand the weight of dense, multi-layered sandwiches, ensuring even pressure across the entire surface.

One of the primary reasons heavy-duty matters is the longevity of the product. Lightweight presses may seem like a more cost-effective choice at first glance, but they often don’t hold up over time. Their flimsy construction can lead to bending, warping, and eventually, a loss of functionality. On the other hand, a heavy-duty sandwich press can withstand the test of time, making it a worthwhile investment for both home cooks and commercial kitchens.

Performance-wise, the weight of a heavy-duty sandwich press contributes to its effectiveness. The added mass ensures that the press applies consistent pressure, which is crucial for achieving that crispy, caramelized crust that is the hallmark of a great sandwich. It’s the difference between a sandwich with a uniform, appealing appearance and one that looks uneven or overcooked in certain areas.

Moreover, heavy-duty presses often feature non-stick surfaces that are more durable than those found in lighter models. This durability means fewer instances of food sticking to the press, reducing the need for scraping or cleaning after each use. For those who appreciate a sandwich press that can maintain its quality and ease of use over the years, this is a significant advantage.

In the realm of comfort and convenience, heavy-duty sandwich presses often come with added features that enhance the user experience. They might have ergonomic handles that reduce hand fatigue, especially during prolonged use, or even adjustable settings for different types of sandwiches. These thoughtful additions are often only possible with the stability and strength provided by a heavy-duty design.

For commercial kitchens, where volume and speed are paramount, the reliability of a heavy-duty sandwich press is non-negotiable. The demands of a bustling café or restaurant require a press that can handle high-frequency use without faltering. A heavy-duty model can withstand the stress of rapid and repetitive pressing, ensuring consistent quality throughout the day.

Beyond the immediate benefits, the psychological satisfaction derived from a heavy-duty sandwich press is undeniable. There’s a certain satisfaction in knowing that you’ve invested in a quality piece of equipment that will serve you well for years to come. It’s not just a tool; it’s a statement of commitment to the craft of making a great sandwich.

In summary, the heavy-duty aspect of sandwich presses is a testament to the importance of durability, performance, and convenience. Whether you’re a home chef or a professional in the food industry, a heavy-duty sandwich press is a reliable companion that can elevate the humble sandwich to an art form. Its ability to endure the rigors of daily use, deliver consistent results, and enhance the overall sandwich-making experience is what makes it an essential and worthwhile addition to any kitchen.

Nestled in the heart of a bustling industrial area, the Heavy Duty Sandwich Press Factory stands as a testament to the evolution of culinary technology. This factory isn’t just a producer of sandwich presses; it’s a beacon of innovation and a cornerstone of the industry. Here’s a glimpse into what makes this factory a hub of creativity and precision.

The factory’s origins trace back to a time when the humble sandwich press was a mere kitchen gadget, often overlooked for its simplicity. Today, it’s a symbol of culinary artistry, and the factory has been at the forefront of this transformation. The presses that roll off the assembly line are not just tools; they are works of engineering that cater to both the home chef and the professional restaurateur.

The design of these heavy-duty sandwich presses reflects a deep understanding of the demands placed on them. They are crafted with robust materials that ensure durability and longevity, capable of withstanding the rigors of daily use in high-volume kitchens. Each press is a blend of form and function, with sleek, modern designs that are as visually appealing as they are practical.

Inside the factory, the craftsmanship is evident in every detail. The presses are built with high-quality metals that are not only durable but also resistant to corrosion and heat. The springs are precision-engineered to apply even pressure, ensuring that every sandwich is cooked to perfection with a golden crust and a melt-in-your-mouth texture.

The factory’s commitment to innovation is palpable. They invest heavily in research and development, constantly pushing the boundaries of what a sandwich press can do. From adjustable heat settings to non-stick surfaces that make cleaning a breeze, the factory’s products are a testament to their dedication to improving the sandwich-making experience.

One of the standout features of the factory’s presses is their versatility. They aren’t just for the classic grilled cheese; they can handle everything from gourmet paninis to deconstructed sushi rolls. The presses are often equipped with interchangeable plates, allowing users to customize their cooking surface to suit their preferences.

The factory’s focus on innovation doesn’t stop at design. They are also at the forefront of sustainability, using environmentally friendly materials and processes in their manufacturing. This commitment to green practices is not just a trend; it’s a core value that guides their operations.

The factory’s team is a mosaic of expertise, from the skilled engineers who design the presses to the meticulous workers who assemble them. Their collective knowledge and passion for their craft are evident in every press that leaves the factory. They understand that the quality of their work directly impacts the quality of the sandwiches that are enjoyed around the world.

The factory’s reputation for excellence has attracted customers from all corners of the globe. Chefs and home cooks alike seek out their products for their superior performance and reliability. The factory’s presses are a staple in many renowned restaurants and cafes, where they are used to create signature dishes that delight the senses.

In the heart of the factory, there’s a sense of pride and purpose. Each employee takes pride in their role in creating a product that brings joy to people’s lives. The factory’s ethos is one of continuous improvement, always looking for ways to better their products and serve their customers.

As the factory continues to innovate, it paves the way for the next generation of sandwich presses. With a focus on functionality, sustainability, and design, the Heavy Duty Sandwich Press Factory is not just a factory—it’s a culinary think tank, a place where the art of the sandwich is redefined with every press that is crafted.

In the competitive world of kitchen appliances, the Heavy Duty Sandwich Press Factory stands out with its exceptional range of products. Here are some of the key features that set their sandwich presses apart from the rest:

The factory’s sandwich presses are crafted with precision engineering, ensuring that every detail is meticulously attended to. The use of high-quality materials, such as stainless steel, guarantees durability and longevity, making these presses not just a tool but a kitchen staple.

One of the standout features is the adjustable pressure mechanism. This allows users to customize the level of compression, from a gentle press to a firm, even cook. Whether you prefer your sandwiches soft and fluffy or crispy and toasted, the factory’s presses cater to a wide range of preferences.

The non-stick surfaces are another game-changer. Not only do they make cleaning a breeze, but they also prevent food from sticking, ensuring that every sandwich is perfectly cooked without the hassle of residue or burnt edges.

The ergonomic design of the factory’s sandwich presses is not just about aesthetics; it’s about functionality. The handles are designed for a comfortable grip, reducing hand fatigue during prolonged use. The compact size of these presses also means they can easily fit into any kitchen, no matter how small the space.

Safety is a top priority, and the Heavy Duty Sandwich Press Factory has not overlooked this aspect. The presses come with heat-resistant handles and a locking mechanism that prevents accidental closure, ensuring a safe cooking experience for all users.

The inclusion of a removable drip tray is a thoughtful addition. It catches any excess grease or moisture, keeping your kitchen counters clean and your cooking area organized. This feature is particularly appreciated by busy cooks who value efficiency and cleanliness.

The factory’s sandwich presses are also versatile, capable of cooking a variety of foods beyond sandwiches. From paninis to grilled cheese, the even heat distribution ensures that each dish is cooked to perfection. This adaptability makes the presses a valuable addition to any kitchen.

The Heavy Duty Sandwich Press Factory understands the importance of innovation, and they continuously refine their products to keep up with the latest trends. This is evident in the inclusion of modern features like digital temperature controls, which allow users to precisely set the desired cooking temperature.

The attention to detail doesn’t stop at the physical features. The factory also offers a range of stylish finishes, from classic black to sleek silver, ensuring that the sandwich press complements any kitchen decor.

Customer satisfaction is at the heart of the Heavy Duty Sandwich Press Factory’s ethos. They offer a comprehensive warranty and excellent customer service, providing peace of mind to those who invest in their products.

In a market flooded with sandwich presses, the Heavy Duty Sandwich Press Factory’s commitment to quality, innovation, and user satisfaction is what truly sets their products apart. From the robust construction to the thoughtful design, these presses are not just tools for cooking; they are investments in the joy of making great sandwiches.

In the ever-evolving landscape of the kitchen appliance industry, the sandwich press has emerged as a staple in homes and commercial kitchens alike. To understand the trends shaping this market, a deep dive into the data reveals several key insights that are reshaping the way we approach the art of sandwich crafting.

The rise of convenience and health consciousness is a driving force behind the popularity of sandwich presses. Data from market research firm Grand View Research indicates that the global sandwich press market size was valued at approximately $300 million in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028. This growth can be attributed to the increasing demand for quick, nutritious meals that are both satisfying and easy to prepare.

One significant trend is the move towards compact and portable sandwich presses. Modern consumers are looking for kitchen gadgets that can be easily stored and transported, making the factory’s sandwich presses with sleek designs and foldable mechanisms particularly appealing. A report by MarketsandMarkets suggests that portable kitchen appliances, which include sandwich presses, are expected to witness a 6.2% CAGR from 2021 to 2026, driven by urbanization and the desire for on-the-go meals.

Customization is another key trend that’s gaining traction. According to a survey conducted by Statista, 65% of consumers prefer products that offer customization options. The sandwich press factory is responding to this by offering models with interchangeable plates, allowing users to make various types of sandwiches, from classic ham and cheese to gourmet avocado toast.

Moreover, there’s a growing demand for smart kitchen appliances. The kitchen tech sector has seen a surge in innovations, with smart devices becoming increasingly integrated into daily life. A study by Grand View Research states that the smart kitchen appliances market is expected to reach $10.5 billion by 2027, driven by the rise of the Internet of Things (IoT). The factory is tapping into this trend by incorporating features such as digital timers, adjustable temperature settings, and connectivity options that allow for remote control via smartphone apps.

The emphasis on sustainability is also a notable trend in the sandwich press industry. Consumers are increasingly aware of the environmental impact of their purchasing decisions. A report by the World Economic Forum highlights that the consumer goods industry is responsible for 60% of the total waste generated globally. In response, the sandwich press factory is exploring eco-friendly materials and production processes, as well as offering repair and recycling services for their products.

In terms of demographics, the sandwich press market is no longer limited to a niche audience. According to a study by Euromonitor International, the 35-44 age bracket accounts for the largest share of sandwich press consumers, but the 25-34 and 45-54 age groups are also showing significant interest. This suggests that the sandwich press has become a versatile kitchen tool that appeals to a broad range of age groups and lifestyle preferences.

When it comes to geographic distribution, the sandwich press market is witnessing strong growth in regions such as North America and Europe. This can be attributed to the high penetration of kitchen appliances in these regions and the increasing number of consumers who value convenience and quality. However, emerging markets such as Asia Pacific are also contributing to the growth, with rising incomes and a growing middle class leading to higher demand for kitchen gadgets.

The data analysis also reveals that the sandwich press industry is seeing a rise in e-commerce sales. Online platforms have become a popular channel for purchasing kitchen appliances, offering consumers a wide range of options and competitive pricing. A report by eMarketer states that global e-commerce sales are expected to reach $5.5 trillion by 2022, indicating that the sandwich press factory needs to have a strong online presence to tap into this growing market segment.

In conclusion, the sandwich press market is being shaped by a variety of trends, including the rise of convenience, health consciousness, customization, smart technology, sustainability, and e-commerce. The factory that stays ahead of these trends will be well-positioned to meet the ever-changing demands of consumers and lead the way in the innovation of sandwich pressing technology.

In the bustling world of kitchen appliances, the heavy-duty sandwich press has emerged as a favorite among home chefs and culinary enthusiasts. These aren’t just your average sandwich makers; they’re the backbone of a culinary craft that’s all about achieving that perfect, golden-brown crust and a juicy, melting interior. Let’s delve into the stories and experiences of those who’ve found success with these powerful tools.

From the cozy confines of home kitchens to the high-pressure environments of cafes and restaurants, the heavy-duty sandwich press has become a symbol of culinary mastery. Consider the tale of Sarah, a stay-at-home mom turned part-time baker. She discovered the joy of crafting gourmet sandwiches using her sturdy press, which allowed her to create impressive meals for her family and friends. The satisfaction on their faces was all the validation she needed to turn her passion into a small, thriving home business.

Then there’s Mark, a seasoned chef at a local diner. His journey with the heavy-duty sandwich press began with a simple goal: to elevate the quality of the diner’s signature sandwiches. With its durable construction and precise temperature control, the press helped him achieve a consistent, professional finish that delighted his patrons. Word of his expertise spread, and soon, Mark was sought after for catering events, bringing the charm of his diner’s kitchen to the forefront.

In the world of food trucks and pop-up eateries, the heavy-duty sandwich press has become an indispensable piece of equipment. Take the story of the ‘Grill and Go’ food truck, where the team relies on their press to deliver high-quality sandwiches on the go. The press’s robust design withstands the rigors of mobile cooking, ensuring that every sandwich is cooked to perfection, no matter the weather or the rush of hungry customers.

One of the most compelling success stories comes from a small, independent café that prides itself on its commitment to local ingredients. The owner, Emily, was looking for a way to differentiate her café from the competition. She invested in a heavy-duty sandwich press and started experimenting with her own unique recipes. The results were stunning, and her café quickly gained a reputation for its exceptional sandwiches, which were a harmonious blend of quality ingredients and expertly cooked to order.

Customers have also shared their personal victories with the sandwich press. Lisa, a self-proclaimed sandwich aficionado, was thrilled to find that she could replicate her favorite café sandwiches at home with the help of her new press. She’s since become a self-taught sandwich artist, hosting pop-up sandwich nights and impressing her guests with her culinary skills.

The impact of the heavy-duty sandwich press extends beyond individual success stories. It’s also reshaping the landscape of foodservice. For instance, the rise of the ‘sandwich bar’ concept has been fueled by the convenience and versatility of these presses. They allow customers to customize their sandwiches, giving them a sense of control and ownership over their meal.

Moreover, the press has become a favorite among food bloggers and influencers. They use it to create visually stunning content, showcasing the art of sandwich making and inspiring their followers to try their hand at it. This, in turn, has sparked a renewed interest in home cooking and the joy of crafting a simple yet satisfying meal.

In conclusion, the heavy-duty sandwich press has become more than just a kitchen gadget; it’s a catalyst for culinary innovation and a source of joy for those who love to cook. From the small home baker to the busy chef, these presses are helping people achieve their culinary dreams and connect with others over the universal love of a great sandwich.

In the world of sandwich presses, sustainability and eco-friendliness are not just buzzwords; they are integral to the ethos of the Heavy Duty Sandwich Press Factory. This factory stands out not only for its durable and high-quality products but also for its commitment to the environment. Here’s a look into how they weave these principles into their operations:

The factory understands that the materials used in manufacturing are crucial to sustainability. They have adopted a stringent selection process for raw materials, choosing suppliers who prioritize sustainable sourcing. This means that the wood, metals, and plastics used in their sandwich presses are not only of the highest quality but also come from responsibly managed forests and recycled sources.

Energy efficiency is another cornerstone of their eco-friendly practices. The factory has invested in state-of-the-art machinery that consumes less energy, reducing their carbon footprint. By optimizing their production processes, they have managed to lower energy consumption by 30% compared to traditional methods.

Water usage is carefully monitored and minimized. The factory employs advanced water recycling systems that capture and treat water used in manufacturing, ensuring that it can be reused in other processes. This not only conserves water but also reduces the amount of wastewater that enters the environment.

Waste reduction is a priority at the Heavy Duty Sandwich Press Factory. They have implemented a comprehensive recycling program that includes everything from paper and packaging materials to metal and plastic components. This not only reduces waste but also saves on disposal costs.

The factory is also committed to reducing its reliance on single-use plastics. They have replaced these with biodegradable or compostable alternatives wherever possible, ensuring that their products are not only durable but also environmentally friendly throughout their lifecycle.

In terms of employee welfare, the factory has implemented green initiatives that encourage a culture of sustainability. Employees are educated on the importance of eco-friendly practices and are encouraged to participate in recycling and conservation efforts. This includes initiatives like a “green team” that organizes environmental clean-up days and promotes energy-saving habits in the workplace.

The factory’s commitment to sustainability extends beyond its own operations. They have formed partnerships with local organizations that focus on environmental conservation and community outreach. Through these collaborations, they support reforestation projects, wildlife protection, and educational programs that raise awareness about environmental issues.

Innovation is key to their approach to sustainability. The factory invests in research and development to find new ways to reduce their environmental impact. This includes exploring alternative materials and production techniques that are more sustainable without compromising on quality.

The Heavy Duty Sandwich Press Factory’s dedication to sustainability is not just a trend; it’s a way of doing business that reflects their values and the needs of the planet. By integrating eco-friendly practices into every aspect of their operations, they are setting a precedent for the industry and demonstrating that sustainability can be profitable and responsible.

The factory’s unwavering dedication to quality and safety is the cornerstone of its operations. From the moment raw materials are sourced to the final product’s delivery, every aspect of the process is meticulously controlled to ensure excellence.

In the realm of quality control, the factory employs a stringent set of standards that are not just met but exceeded. Skilled technicians and engineers are constantly refining their craft, ensuring that each sandwich press that rolls off the assembly line is not just functional but also a testament to precision engineering. The use of high-grade materials and state-of-the-art manufacturing techniques guarantees durability and reliability.

Safety is equally paramount. The factory adheres to the strictest safety protocols, both in the workplace and in the products it produces. Regular health and safety audits are conducted to identify and mitigate potential risks, and employees are trained in the latest safety procedures. This commitment is not just about compliance with regulations; it’s about fostering a culture where safety is a shared responsibility and a top priority.

The factory’s products are designed with the end-user in mind. Features like non-slip bases, heat-resistant handles, and easy-to-clean surfaces are just a few examples of how the factory prioritizes safety. The design team works closely with safety experts to ensure that every detail of the sandwich press is thought through, from the sturdy construction to the intuitive controls.

Moreover, the factory’s commitment to quality and safety extends beyond the manufacturing floor. It includes a robust quality assurance program that encompasses every stage of the supply chain. Suppliers are rigorously vetted to ensure that they meet the same high standards as the factory itself. This proactive approach to quality and safety ensures that the final product is not just a tool but a reliable companion in the kitchen.

In the event of a product issue, the factory’s customer service team is ready to assist. They are well-trained to handle inquiries and provide solutions swiftly, often offering replacements or repairs to ensure customer satisfaction. This level of service reinforces the factory’s commitment to its customers and their safety.

The factory also invests in ongoing research and development to stay ahead of safety trends. By staying informed about the latest advancements in materials and manufacturing processes, the factory can continuously improve its products. This proactive stance means that customers can trust that their sandwich press is not only safe but also equipped with the latest innovations.

The factory’s commitment to quality and safety is not just a corporate responsibility; it’s a promise to the consumer. It’s about building trust through consistency and reliability, and it’s a promise that the factory takes very seriously. Whether it’s a small detail like the inclusion of a child-safe lock or a larger initiative like a comprehensive safety training program for employees, the factory’s actions speak louder than words.

In a world where quality and safety are often compromised for the sake of cost, the factory stands as a beacon of excellence. It’s a testament to the belief that a product is only as good as the care and attention put into its creation. For the factory, quality and safety are not just buzzwords; they are the very essence of what it means to deliver a product that not only performs well but also does so with peace of mind.

In the ever-evolving world of culinary arts, the way we prepare and enjoy sandwiches is undergoing a fascinating transformation. Innovations in sandwich making are not just about convenience; they’re about enhancing flavor, texture, and presentation. The future of sandwich making is a blend of tradition and technology, where the humble sandwich becomes a canvas for culinary creativity.

The advent of new techniques and ingredients has opened up a world of possibilities. We’re seeing a surge in gourmet sandwiches that push the boundaries of taste, with unique flavor combinations that cater to a wide range of palates. Think of the fusion of Italian, Asian, and Middle Eastern flavors in a single sandwich, creating a symphony of tastes that challenges the traditional notion of what a sandwich can be.

Customization is another key trend. With the rise of food trucks and pop-up restaurants, sandwiches are being tailored to suit individual preferences. Customers can now choose from a variety of breads, fillings, condiments, and toppings, making each sandwich a personalized culinary experience. This level of customization is not just about personal taste; it’s also about catering to dietary restrictions and preferences, ensuring that everyone can enjoy a delicious sandwich.

Technology is playing a pivotal role in shaping the future of sandwich making. Smart kitchen gadgets are becoming increasingly popular, offering precise control over cooking temperatures and times. For instance, high-tech sandwich presses are not just for even toasting; they can also lock in flavors and textures, ensuring that every bite is perfect. Additionally, digital recipes and meal prep apps are making it easier for home cooks to experiment with new sandwich ideas.

Sustainability is also a driving force in the industry. There’s a growing movement towards using locally sourced, organic, and non-GMO ingredients. Not only does this support local farmers and reduce the carbon footprint, but it also leads to fresher, more flavorful sandwiches. The future of sandwich making will likely see a greater emphasis on sustainable practices, from the sourcing of ingredients to the packaging and disposal of waste.

Innovation in the way we think about sandwiches is also expanding. We’re seeing the rise of “sandwich bars” where customers can mix and match ingredients to create their own masterpieces. These bars are not just a place to buy a sandwich; they’re a destination for foodies to experience the joy of creating their own culinary art.

The use of alternative proteins is another trend that’s shaping the future of sandwich making. With the increasing awareness of environmental impact and health concerns, plant-based and lab-grown meats are becoming more prevalent. These options offer a sustainable and healthy alternative to traditional meat sandwiches, appealing to a broader audience.

Moreover, the way we eat sandwiches is changing. The rise of the “sandwich box” is a testament to the convenience and portability of sandwiches. These compact, eco-friendly boxes are perfect for on-the-go meals, ensuring that a delicious sandwich can be enjoyed anywhere, anytime.

Lastly, the global influence on sandwich making cannot be overlooked. The world’s culinary traditions are blending, and this has led to the creation of unique and international sandwich styles. From the Japanese gyros to the Indian dosa, the future of sandwich making is a melting pot of flavors and techniques.

In conclusion, the future of sandwich making is an exciting and dynamic landscape. It’s a place where tradition meets innovation, sustainability is key, and the joy of culinary exploration is at the forefront. Whether it’s through high-tech gadgets, personalized customization, or global culinary influences, the sandwich is set to remain a beloved staple in the culinary world, evolving with the times and the tastes of the people who love it.