Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where global trade shapes the landscape of many industries, the kitchen appliances sector is no exception. As markets evolve and consumer preferences shift, the era of import substitution has emerged as a pivotal trend. This shift not only reshapes the competitive dynamics but also presents a unique opportunity for local manufacturers to redefine their place in the market. This piece delves into the strategies and challenges that accompany this transformation, highlighting the path forward for suppliers looking to capitalize on the import substitution era.

The kitchen appliance market has undergone a significant transformation, with a notable shift towards import substitution. This trend is not just a mere economic adjustment but a testament to the growing capabilities and aspirations of local manufacturers. As the world becomes more interconnected, the allure of locally produced appliances is gaining traction, offering a blend of quality, affordability, and cultural pride.

With the rise of import substitution, local suppliers are stepping up their game, leveraging advanced technologies and innovative designs to capture the hearts of consumers. This shift is not just about reducing dependence on foreign imports; it’s about fostering a domestic industry that can compete on the global stage. The kitchen appliances sector is at the forefront of this movement, driven by a combination of strategic policies, technological advancements, and consumer demand.

Consumer preferences have also played a pivotal role in this shift. The desire for appliances that are not only functional but also reflective of local tastes and aesthetics has been a major driver. Modern consumers are more conscious of sustainability and are gravitating towards appliances that are eco-friendly and locally made. This shift in consumer mindset has opened up new opportunities for local manufacturers to differentiate themselves in a highly competitive market.

Governments around the world have been supportive of import substitution programs, recognizing their potential to stimulate domestic industries, create jobs, and reduce trade deficits. These policies often involve tax incentives, subsidies, and protective tariffs that help level the playing field for local suppliers. In the kitchen appliances sector, such measures have encouraged domestic production and have led to the development of sophisticated manufacturing facilities.

The technological landscape has also been a significant enabler of import substitution. Local suppliers are now able to produce appliances that rival those from international brands, thanks to advancements in robotics, automation, and materials science. This technological edge has allowed local manufacturers to offer high-quality appliances at competitive prices, making them an attractive alternative to imported goods.

Moreover, the quality of domestic appliances has significantly improved over the years. Local brands are investing heavily in research and development to ensure their products meet international standards. This focus on quality has been a game-changer, as consumers are increasingly willing to choose local over imported products when they perceive equal or better value.

The rise of import substitution in kitchen appliances is also being fueled by the rise of e-commerce. Online platforms have made it easier for local suppliers to reach a wider audience, bypassing traditional distribution channels. This direct-to-consumer approach has not only increased sales but has also provided valuable feedback that local manufacturers use to refine their products.

Despite these advancements, challenges remain. Local suppliers often face issues related to economies of scale, brand recognition, and access to global supply chains. However, these hurdles are being tackled through strategic partnerships, joint ventures, and the adoption of global best practices.

One cannot ignore the role of design in the success of import substitution. Local brands are increasingly focusing on creating appliances that not only serve a functional purpose but also enhance the aesthetic appeal of modern kitchens. This emphasis on design has helped in creating a distinct identity for domestic appliances, making them a point of pride for consumers.

In conclusion, the rise of import substitution in the kitchen appliances industry is a multifaceted phenomenon, driven by economic, technological, and consumer-driven factors. As local suppliers continue to innovate and improve, the future looks bright for this sector, with the potential to become a global leader in the production of quality kitchen appliances.

In the ever-evolving kitchen appliances industry, understanding the intricate market dynamics is crucial for both established players and emerging brands. Consumer preferences are shifting rapidly, driven by technological advancements, changing lifestyles, and economic factors. Here’s a closer look at some key dynamics shaping the industry.

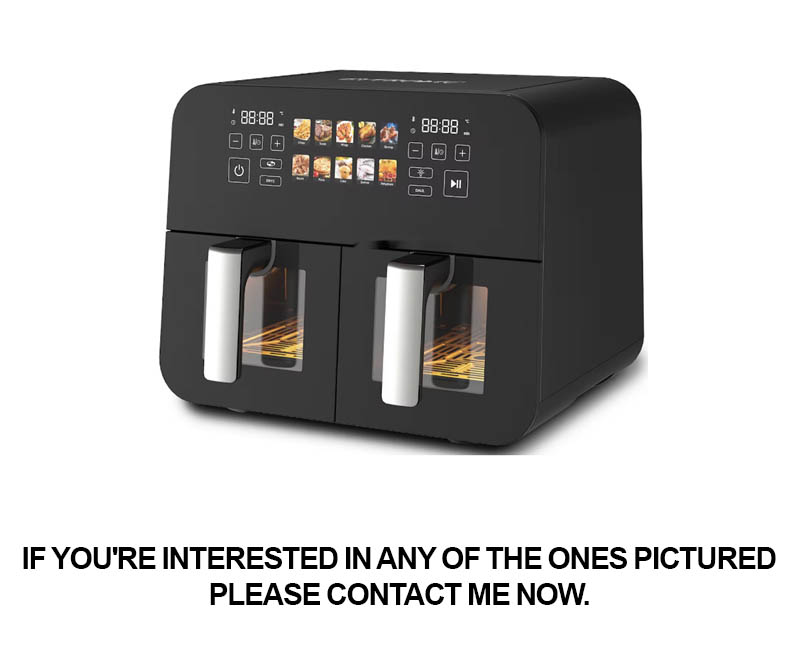

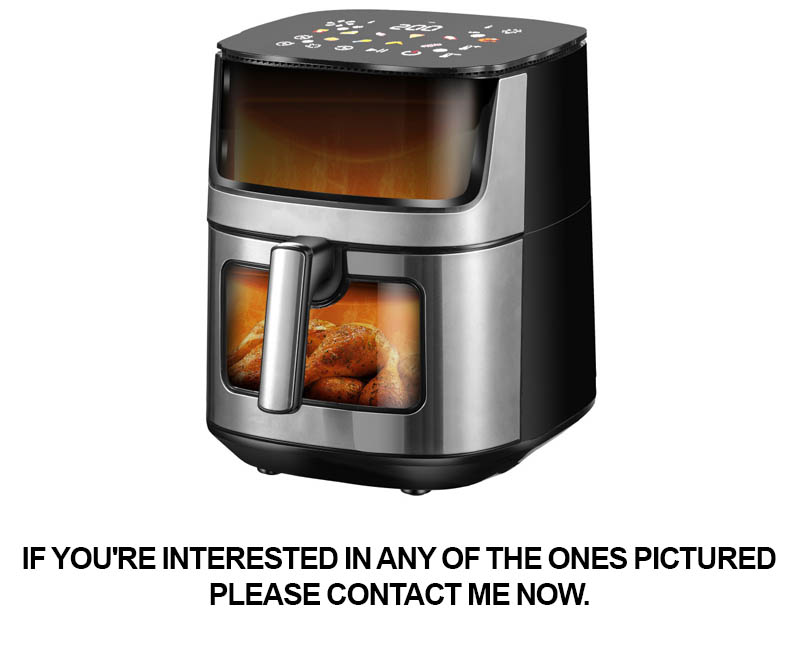

Consumer Trends and PreferencesThe rise of health-conscious consumers has led to a surge in demand for kitchen appliances that promote healthy cooking methods, such as air fryers and slow cookers. Smart kitchen gadgets, which offer connectivity and convenience, are also gaining popularity. Additionally, the preference for energy-efficient and eco-friendly appliances is on the rise, reflecting a broader environmental consciousness.

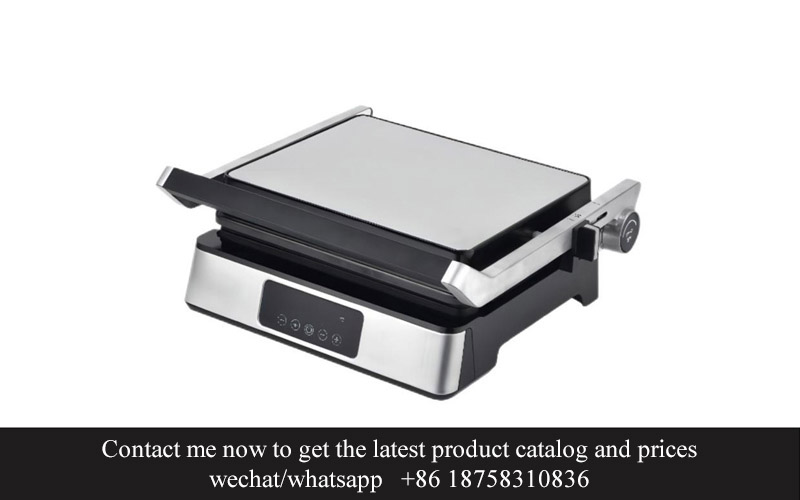

Technological IntegrationTechnology is a driving force behind the market dynamics in the kitchen appliances industry. From touchscreens to voice-activated controls, smart appliances are becoming the norm. IoT (Internet of Things) integration allows for greater connectivity and automation, offering consumers a seamless kitchen experience. Brands that fail to innovate technologically risk falling behind the competition.

Market SegmentationThe kitchen appliances market is segmented by product type, such as refrigerators, dishwashers, ovens, and small appliances. Each segment has its own set of trends and consumer needs. For instance, the premium appliance market is growing, with consumers willing to pay more for high-quality, durable products. Meanwhile, the budget segment is also vital, as it serves a broader consumer base looking for affordable solutions.

Globalization and Trade PoliciesGlobalization has opened up new markets for kitchen appliance manufacturers, but it also brings challenges. Trade policies, such as tariffs and import restrictions, can significantly impact the cost of goods and availability. For instance, the import substitution program in certain regions encourages the use of locally produced appliances, which can affect international suppliers and manufacturers.

Distribution ChannelsThe way kitchen appliances are sold has evolved. Traditional brick-and-mortar retailers still play a significant role, but online sales are growing rapidly. E-commerce platforms provide consumers with a wider range of options and the convenience of home delivery. This shift necessitates a strong online presence and effective digital marketing strategies for manufacturers and suppliers.

Competitive LandscapeThe competitive landscape in the kitchen appliances industry is intense, with both established brands and new entrants vying for market share. Key players are known for their innovation, brand loyalty, and extensive product lines. Smaller brands often differentiate themselves through niche products or unique features that appeal to specific consumer segments.

Regulatory EnvironmentRegulatory standards and certifications are a critical factor in the kitchen appliances industry. Safety, energy efficiency, and environmental regulations can vary by region, requiring manufacturers to navigate complex compliance requirements. These regulations can also drive innovation, as companies strive to meet the latest standards.

Brand Loyalty and MarketingBrand loyalty remains a cornerstone of the kitchen appliances industry. Consumers are often willing to pay a premium for appliances from trusted brands. Effective marketing strategies, including social media campaigns, influencer partnerships, and targeted advertising, are essential for building and maintaining brand loyalty.

Emerging MarketsEmerging markets, particularly in Asia and Africa, offer significant growth opportunities. These regions have a growing middle class with increasing disposable income, leading to a surge in demand for kitchen appliances. Local manufacturers and international players alike are targeting these markets with tailored products and services.

Sustainability and Corporate Social ResponsibilitySustainability is becoming a key consideration for consumers and businesses alike. Companies that prioritize eco-friendly practices, sustainable materials, and corporate social responsibility are likely to gain a competitive edge. This dynamic is prompting the industry to explore alternatives to traditional materials and manufacturing processes.

In conclusion, the market dynamics in the kitchen appliances industry are complex and multifaceted. By staying attuned to consumer trends, embracing technological advancements, navigating trade policies, and focusing on sustainability, manufacturers and suppliers can position themselves for success in this dynamic sector.

In the ever-evolving world of kitchen appliances, innovation is key to staying ahead of the curve. Here are some fresh perspectives on innovative ideas that could redefine the kitchen appliance landscape.

The integration of smart technology is no longer a novelty but a necessity. Imagine a refrigerator that not only keeps your food fresh but also suggests recipes based on the contents. By leveraging AI, these appliances can learn your preferences and even order groceries when supplies are low.

Energy efficiency is a growing concern, and kitchen appliances are no exception. Designers are now focusing on creating appliances that use less power without compromising performance. For instance, induction cooktops are gaining popularity for their ability to heat food faster and more efficiently than traditional electric or gas burners.

Interactive appliances that can communicate with users through voice commands or a dedicated app are becoming increasingly common. Picture a stove that adjusts its temperature based on the type of pan you’re using or an oven that sends cooking instructions directly to your smartphone. This level of personalization is not just convenient but also educational, guiding users towards healthier cooking habits.

The rise of modular kitchen appliances is another interesting trend. These units can be customized to fit any kitchen layout and can be upgraded as technology advances. Imagine a countertop unit that starts as a compact microwave and can expand into a full-fledged kitchen island with additional features like a sink, oven, and even a small refrigerator.

Sustainability is a driving force in the kitchen appliance industry. Innovators are exploring the use of recycled materials and eco-friendly designs. For example, dishwashers made from recycled plastic or ovens that use solar power to preheat could soon become the norm.

In the realm of cleaning, the development of self-cleaning appliances is a game-changer. From self-cleaning ovens that use steam to sanitize surfaces to refrigerators with automated cleaning cycles, these innovations promise to reduce the time and effort spent on kitchen chores.

Safety features are also being reimagined. Appliances with built-in sensors that can detect gas leaks or overheating are becoming standard. Moreover, childproofing has taken a technological leap with appliances that can be locked with biometric scans or PIN codes.

The kitchen of the future may also see appliances that are more visually appealing. Materials like glass, metal, and wood are being used in creative ways to create sleek, modern designs that blend seamlessly with any kitchen decor.

In terms of connectivity, appliances are becoming part of a larger ecosystem. They can be controlled remotely, share data with other smart devices, and even offer predictive maintenance. This means your kitchen appliances could alert you to potential issues before they become problems.

Lastly, the customization of kitchen appliances is expanding beyond just size and color. Users are increasingly interested in appliances that can be tailored to their specific needs, whether it’s a gluten-free setting on a blender or a high-temperature setting for sous-vide cooking.

As the kitchen appliance industry continues to innovate, it’s clear that the future holds a multitude of possibilities. From smart, efficient appliances to those that are environmentally conscious and user-friendly, the kitchen of tomorrow will be a testament to human ingenuity and the relentless pursuit of better living.

In the midst of the global shift towards import substitution programs, local suppliers play a pivotal role in reshaping the kitchen appliances industry. Their contribution is multifaceted, encompassing not just the supply chain but also innovation, quality control, and market adaptation.

The first layer of their impact lies in the raw materials. Local suppliers ensure that the necessary components for kitchen appliances are readily available, reducing dependency on international markets. This not only stabilizes prices but also shortens lead times, allowing manufacturers to respond quickly to market demands.

Furthermore, by sourcing locally, manufacturers can foster a more sustainable and environmentally friendly production process. The reduction in transportation emissions and the support of local economies are significant benefits that resonate with today’s eco-conscious consumers.

Innovation is another area where local suppliers excel. They often have a deeper understanding of local preferences and needs, leading to the development of products that cater specifically to the regional market. This can range from kitchen appliances designed to handle local cooking styles to those that are energy-efficient and adapted to local power supplies.

Quality control is also crucial, and local suppliers are well-positioned to ensure high standards. Their proximity to the manufacturing facilities allows for easier oversight and quicker responses to any quality issues. This direct involvement can lead to appliances that are more reliable and less prone to defects.

Moreover, local suppliers are adept at navigating the complexities of the domestic market. They understand the regulations, certifications, and distribution channels that are unique to each country. This expertise is invaluable in navigating the intricacies of the import substitution program, ensuring that products meet all necessary requirements.

The importance of local suppliers extends beyond the manufacturing floor. They often act as a bridge between the consumer and the product, providing valuable feedback that can drive improvements. This two-way dialogue is essential for tailoring products to the evolving tastes and needs of the local population.

In the realm of service and support, local suppliers can offer a significant advantage. With service centers and repair shops more easily accessible, customers can expect quicker response times and more personalized care. This aspect of the supply chain is critical in maintaining customer satisfaction and brand loyalty.

The economic impact of local suppliers in the import substitution program cannot be overstated. By supporting domestic manufacturing, these suppliers help to create jobs and stimulate economic growth within the country. This, in turn, can lead to a more robust and resilient local economy.

However, the role of local suppliers is not without its challenges. The competition from established international brands can be fierce, and the need for constant innovation and improvement is paramount. Local suppliers must also navigate the complexities of trade policies and tariffs, which can fluctuate and impact the cost-effectiveness of their products.

Despite these challenges, the potential for growth and success is substantial. As the import substitution program gains traction, local suppliers will continue to play a critical role in shaping the kitchen appliances industry. Their ability to adapt, innovate, and meet the demands of a changing market will be key to their success.

The importance of local suppliers in the import substitution program is further highlighted by their role in fostering a sense of national pride. By promoting domestic products, these suppliers contribute to a narrative of self-sufficiency and independence. This not only resonates with consumers but also supports the broader goal of national economic development.

In conclusion, local suppliers are more than just intermediaries in the kitchen appliances industry; they are catalysts for change. Their role in the import substitution program is multifaceted, touching on every aspect of the supply chain, from raw materials to customer satisfaction. As the program continues to evolve, the contribution of these suppliers will only grow more significant, driving the industry towards a more sustainable and self-reliant future.

The integration of smart technology has become a cornerstone in the kitchen appliances industry, offering users a blend of convenience and efficiency. Smart ovens, refrigerators, and dishwashers are not just cooking or storing food; they’re becoming part of a larger smart home ecosystem, communicating with other devices to optimize performance and energy use.

Energy efficiency is a key trend that has gained significant traction. With environmental concerns on the rise, manufacturers are focusing on appliances that consume less energy while maintaining their functionality. This shift is reflected in the growth of LED lighting in kitchen appliances and the development of more energy-saving motors and heating elements.

Customization is another trend reshaping the industry. Consumers are no longer looking for one-size-fits-all solutions; they want appliances that cater to their specific needs and preferences. This has led to a surge in personalized kitchen appliances, from custom-sized refrigerators to smart appliances that can be controlled via mobile apps based on individual usage patterns.

Health and wellness are becoming more integral to kitchen appliances. We’re seeing a rise in appliances designed to enhance the nutritional value of food, such as sous-vide cookers that maintain precise temperatures for optimal food quality, and air fryers that offer a healthier alternative to traditional frying methods.

Sustainability is a growing concern, and the kitchen appliances industry is responding with eco-friendly designs. Materials are being chosen for their recyclability, and appliances are being designed to last longer, reducing the frequency of replacements. The use of renewable energy sources in manufacturing processes is also becoming more prevalent.

Market data indicates a strong demand for multifunctional appliances. Combining multiple functions into a single unit not only saves space but also reduces the complexity of kitchen setups. For example, a single unit that can function as a microwave, convection oven, and air fryer is highly appealing to consumers looking to streamline their kitchen.

Sales of small kitchen appliances are on the rise, driven by the popularity of single-serve and on-the-go lifestyles. Blenders, toasters, and single-serve coffee makers are becoming staples in many homes, offering convenience and ease of use.

The use of 3D printing in kitchen appliance design is becoming more sophisticated. This technology allows for the creation of complex and highly customized parts that can improve the performance and aesthetics of appliances. As the technology advances, we can expect to see more innovative designs that push the boundaries of traditional manufacturing.

Consumer preferences are shifting towards simplicity and minimalism. There’s a growing trend towards appliances that have clean lines, neutral colors, and a sleek design, reflecting the desire for a more streamlined and elegant kitchen aesthetic.

Data analysis reveals that the kitchen appliances industry is becoming increasingly competitive. New entrants are constantly challenging established players, and the pace of innovation is accelerating. This competition is driving the industry towards more efficient production methods and more affordable pricing for consumers.

Lastly, the importance of user experience cannot be overstated. The industry is focusing on improving the interface design of appliances, making them more intuitive and user-friendly. From touchscreens to voice commands, the emphasis is on creating a seamless and enjoyable experience for the user.

In the realm of import substitution, several case studies have emerged as shining examples of how countries can successfully reduce reliance on foreign goods and foster local industries. Here’s a closer look at some of these successful initiatives:

The Mexican Automotive Industry’s ResurgenceMexico once heavily relied on imported cars, but through strategic import substitution, the country has transformed its automotive sector. By establishing local manufacturing facilities and fostering partnerships with international brands, Mexican companies have not only reduced imports but also gained a competitive edge in the global market. This has been achieved through government incentives, local talent development, and a focus on high-quality components.

Brazil’s Sugar-Ethanol RevolutionBrazil’s import substitution program in the sugar-ethanol industry has been a remarkable success. By investing in domestic sugar cane processing, Brazil has become the world’s largest ethanol producer, reducing its dependence on imported oil. This shift has not only bolstered the country’s energy independence but also created jobs and stimulated economic growth in rural areas.

Turkey’s Textile and Apparel Industry GrowthTurkey’s import substitution in the textile and apparel sector has been a testament to the power of localization. By investing in modern manufacturing facilities, improving production techniques, and promoting local brands, Turkey has successfully reduced its reliance on foreign clothing. The industry now supports millions of jobs and has made Turkey a key player in the global textile market.

South Korea’s Electronics Industry LeapSouth Korea’s rise in the electronics industry is a classic example of import substitution. Once a consumer of Japanese and American electronics, South Korea developed its own brands and technology, leading to the creation of global giants like Samsung and LG. By focusing on research and development, the country has not only cut down on imports but also become a leading exporter of electronics.

China’s Mobile Phone Manufacturing SuccessChina’s import substitution in the mobile phone industry is a story of rapid growth and innovation. By investing in domestic production and leveraging the country’s vast pool of skilled labor, China has become the world’s largest mobile phone manufacturer. Local brands like Huawei and Xiaomi have surged ahead, challenging global giants and reducing the need for imported devices.

Argentina’s Beef Industry RevivalArgentina’s beef industry faced challenges due to high import dependence, but through a combination of domestic production and export promotion, the country has managed to revitalize its beef sector. By implementing quality control measures and expanding its market reach, Argentina has reduced its reliance on imported meats and become a major player in the global beef market.

Taiwan’s Semiconductor Industry LeadershipTaiwan’s semiconductor industry has grown from a reliance on imported technology to a position of global leadership. By investing in research and development, fostering a skilled workforce, and creating a supportive ecosystem, Taiwan has become a powerhouse in the semiconductor market. This has not only reduced imports but also made the country a key player in the global tech supply chain.

Indonesia’s Palm Oil Industry GrowthIndonesia’s palm oil industry has seen significant growth through import substitution. By focusing on sustainable practices and expanding domestic production, Indonesia has become the world’s largest palm oil exporter. This shift has not only reduced the country’s dependence on imported oils but also created jobs and supported rural economies.

These case studies demonstrate the potential for import substitution to drive economic growth, create jobs, and enhance a country’s self-sufficiency. By focusing on local production, investing in technology, and fostering innovation, nations can successfully reduce their reliance on imported goods and strengthen their domestic industries.

In the competitive landscape of the kitchen appliances industry, local manufacturers face a unique set of challenges and opportunities. Balancing the pressure to innovate with the need to maintain affordability, these players are navigating a complex terrain where market demands and technological advancements are in a constant state of flux.

The rise of smart kitchen appliances has opened up new avenues for local manufacturers to differentiate themselves. With consumers increasingly seeking connectivity and convenience, companies that can integrate smart technology into their products are likely to gain a competitive edge. However, this shift requires significant investment in research and development, which can be a hurdle for smaller, local firms.

Moreover, the demand for sustainable and eco-friendly appliances is on the rise. Local manufacturers that can leverage their proximity to natural resources and embrace green manufacturing practices have the opportunity to tap into a growing market segment. This not only benefits the environment but also resonates with consumers who are becoming more conscious of their ecological footprint.

One challenge local manufacturers often encounter is the high cost of raw materials. Fluctuations in global commodity prices can impact production costs, making it difficult for these companies to maintain profitability. Yet, some have found success by focusing on locally sourced materials, which can offer more stable pricing and a closer relationship with suppliers.

Another opportunity lies in the customization of products. As consumers seek appliances that cater to their specific needs, local manufacturers can capitalize on their ability to provide tailored solutions. This requires a flexible supply chain and a willingness to engage in customer-centric design, but it also allows for premium pricing and customer loyalty.

The integration of advanced manufacturing techniques, such as 3D printing and robotics, is another area where local manufacturers can excel. These technologies can streamline production, reduce waste, and enable the creation of complex, customized products. However, the initial investment and training required can be substantial, and not all local firms have the resources to adopt these technologies.

In terms of distribution, local manufacturers often have a leg up due to their established networks and local knowledge. They can more easily navigate the complexities of the supply chain and distribute their products to remote areas. This local expertise can also be a selling point, as consumers may prefer to support businesses that understand their local market dynamics.

Yet, the challenge of brand recognition remains a significant hurdle. Local manufacturers often struggle to compete with well-known international brands that have global marketing budgets and distribution networks. To overcome this, some have turned to e-commerce and social media to build their brand presence, reaching consumers directly and leveraging the power of online reviews and word-of-mouth.

The rise of the gig economy and the increasing popularity of online marketplaces have also presented opportunities for local manufacturers. They can now collaborate with freelancers and small businesses to create a more agile and cost-effective production process. This decentralized approach allows for rapid prototyping and scaling, which can be particularly beneficial for new or niche products.

Lastly, the opportunity to collaborate with educational institutions and research organizations cannot be overstated. By fostering partnerships, local manufacturers can tap into a wealth of knowledge and talent, driving innovation and keeping their products at the forefront of technological advancements.

In conclusion, while challenges abound, local manufacturers in the kitchen appliances industry have numerous opportunities to thrive. By focusing on innovation, sustainability, customization, and leveraging their unique advantages, these companies can carve out a successful niche in a rapidly evolving market.

In the ever-evolving landscape of consumer preferences, there’s a growing trend towards embracing domestic appliances. This shift isn’t just about supporting local businesses; it’s about recognizing the unique benefits that these products offer. Let’s delve into the reasons why consumers are increasingly turning to domestic appliances.

People are becoming more environmentally conscious, and domestic appliances often come with a lower carbon footprint compared to imported ones. Local manufacturing processes are typically more efficient and sustainable, reducing waste and energy consumption. This eco-friendly approach resonates with consumers who are keen on reducing their environmental impact.

The quality of domestic appliances has significantly improved over the years. Many local manufacturers have invested in advanced technology and skilled labor to produce high-quality products that rival those from international brands. Consumers are noticing this quality boost and are more inclined to invest in appliances that are made with care and precision.

Local appliances often come with a personal touch that international brands might lack. The design and functionality are tailored to the specific needs and preferences of the local market. This means that domestic appliances are not only practical but also aesthetically pleasing, fitting seamlessly into the consumer’s home decor.

The cost factor plays a pivotal role in the consumer’s decision to choose domestic appliances. While imported products may seem appealing due to their brand recognition, they often come with a higher price tag. Domestic appliances, on the other hand, offer competitive pricing without compromising on quality. Consumers are finding that they can get more for their money when they opt for locally produced goods.

The support for local manufacturers is a significant motivator for many consumers. Buying domestic appliances means contributing to the local economy, creating jobs, and fostering community growth. This sense of contribution and loyalty to local businesses is a powerful driver in the consumer’s choice to embrace domestic appliances.

Another aspect that consumers are considering is the availability and after-sales service. Domestic appliances are usually more accessible and come with better customer support. Local suppliers can provide quicker response times and more personalized service, which is particularly appealing to those who value convenience and support.

The rise of technology has also played a role in the popularity of domestic appliances. Many local manufacturers are at the forefront of integrating smart technology into their products, offering consumers cutting-edge features that enhance convenience and efficiency. This technological edge is something that domestic appliances can provide without the need for international shipping delays.

Moreover, there’s a sense of pride that comes with owning and using domestic appliances. Consumers are proud to showcase their support for local talent and innovation. This pride extends beyond the purchase itself, influencing how consumers feel about their homes and their contribution to the community.

In conclusion, the consumer’s perspective on embracing domestic appliances is multifaceted. It’s driven by environmental concerns, the quality and design of local products, cost-effectiveness, support for local businesses, accessibility, and technological advancements. As consumers continue to prioritize these factors, the demand for domestic appliances is likely to grow, reflecting a shift towards a more localized and sustainable approach to living.

Navigating the landscape of import substitution, suppliers must adapt and capitalize on the shift towards domestic products. This involves a multifaceted approach that encompasses understanding consumer needs, leveraging local resources, and fostering innovation. Here’s how suppliers can thrive in this evolving market:

Consumer EducationSuppliers need to bridge the knowledge gap by educating consumers about the benefits of domestic appliances. Emphasizing quality, sustainability, and support systems can help shift perceptions from imported to locally made products.

Collaboration with Local ManufacturersBy partnering with local manufacturers, suppliers can ensure a seamless supply chain. This collaboration allows for better control over production timelines, quality standards, and cost efficiency.

Customization and Local Market TrendsSuppliers should focus on tailoring their offerings to local preferences and trends. This could mean designing appliances that cater to regional cooking styles or incorporating features that are more relevant to local households.

Investing in Quality ControlMaintaining high-quality standards is crucial. Suppliers must invest in rigorous quality control measures to ensure that their products meet or exceed local and international benchmarks.

Marketing and BrandingEffective marketing and branding are key to success. Suppliers should leverage social media, influencer partnerships, and local events to showcase their products and build a brand that resonates with consumers.

After-Sales ServiceProviding exceptional after-sales service can be a game-changer. By ensuring that customers have easy access to repair and maintenance services, suppliers can build trust and loyalty.

Innovation and Research and DevelopmentContinual innovation is vital. Suppliers should invest in R&D to develop new products that not only meet current needs but also anticipate future trends.

Price Sensitivity and AffordabilityUnderstanding the price sensitivity of the local market is essential. Suppliers should balance the need for affordability with the quality and features that consumers desire.

Sustainability and Environmental ConsiderationsAs sustainability becomes a key concern, suppliers should prioritize eco-friendly appliances. This not only aligns with consumer values but also opens up new market opportunities.

DiversificationRelying on a single product line can be risky. Suppliers should consider diversifying their offerings to include complementary products that cater to different segments of the market.

Government Incentives and SupportSuppliers should look for government incentives and support programs that are designed to encourage local manufacturing and import substitution. This could include subsidies, tax breaks, or grants.

Networking and PartnershipsBuilding a strong network of suppliers, manufacturers, and retailers can enhance market reach and distribution channels. Collaborative efforts can lead to better resource allocation and shared knowledge.

Feedback and Continuous ImprovementRegularly collecting feedback from customers and stakeholders can provide invaluable insights. Suppliers should use this information to continuously improve their products and services.

Risk ManagementAnticipating and managing risks is crucial. This includes supply chain disruptions, fluctuating exchange rates, and changes in government policies.

Long-Term VisionFinally, suppliers should have a long-term vision for their role in the import substitution program. This involves not just adapting to the current market but also planning for future growth and sustainability.

The import substitution era is reshaping the landscape of the kitchen appliances market, offering both challenges and unprecedented opportunities. As we ponder the future, it’s clear that innovation, strategic partnerships, and a deep understanding of consumer needs will be the cornerstones of success for suppliers in this new era.

Consumer preferences are evolving, and with them, the demands placed on kitchen appliances. Smart features, energy efficiency, and eco-friendly materials are becoming increasingly important. Suppliers must adapt by investing in research and development to create products that not only meet these standards but also exceed them, offering unique solutions that resonate with the modern consumer.

The importance of local suppliers cannot be overstated. By supporting domestic manufacturers, consumers are not only investing in their local economy but also fostering a sense of community and pride. This support can translate into more robust and tailored product lines, as local suppliers are better equipped to understand and anticipate the specific needs of their customer base.

In the wake of import substitution, the demand for customization and personalization is on the rise. Suppliers who can offer appliances that can be easily modified or upgraded to fit individual lifestyles will have a significant edge. This could mean anything from modular designs that allow for the addition of new features to appliances that can be controlled through smart devices.

The integration of technology into kitchen appliances continues to be a game-changer. Suppliers who embrace the Internet of Things (IoT) and develop appliances that can communicate with each other and with the user’s smart home system will find a ready market. This interconnectedness not only enhances the user experience but also opens up new revenue streams through subscription services and data analytics.

Sustainability is more than just a buzzword; it’s a critical factor in the future of kitchen appliances. Suppliers who can demonstrate a commitment to environmental responsibility through sustainable sourcing, manufacturing processes, and product end-of-life recycling will win over eco-conscious consumers and attract government incentives.

The rise of the health-conscious consumer has also had a profound impact on the kitchen appliances market. Appliances that promote healthy cooking methods, such as slow cookers and air fryers, are becoming increasingly popular. Suppliers need to be at the forefront of these trends, offering innovative solutions that align with the desire for nutritious and delicious meals.

As the landscape shifts, the importance of building strong brand identities cannot be underestimated. Brands that stand for quality, reliability, and innovation will be the ones that consumers turn to when making purchasing decisions. Suppliers must invest in marketing and branding strategies that highlight their unique selling propositions and differentiate them from competitors.

The importance of partnerships and collaborations cannot be overstated. By joining forces with local manufacturers, suppliers can leverage each other’s strengths and create a more cohesive and competitive offering. This could mean sharing resources, technology, or even knowledge, leading to a more robust and diverse product range.

The future of kitchen appliances in the import substitution era is not just about the products themselves; it’s about the entire ecosystem surrounding them. Suppliers who can provide a seamless customer experience, from product design to after-sales service, will be the ones who thrive. This means investing in training for sales and service teams, ensuring they are equipped to handle the unique demands of a changing market.

As we look ahead, it’s clear that the future of kitchen appliances will be characterized by a blend of traditional values and cutting-edge technology. Suppliers who can navigate this complex terrain will find that the opportunities are vast, from new markets to innovative business models. The key is to remain adaptable, customer-focused, and forward-thinking, always ready to embrace the next wave of innovation that will shape the future of kitchen appliances.