Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving culinary landscape, the sandwich grill industry has seen remarkable transformations. As consumer tastes shift and demand for convenience grows, understanding the dynamics at play and the innovations shaping this sector is crucial. This article delves into the intricate world of continuous operation sandwich grill plants, exploring their features, the impact of their design and functionality, and the broader market trends that drive consumer preferences. Through case studies and an analysis of challenges and potential solutions, we aim to paint a comprehensive picture of the industry’s current state and future trajectory.

In the fast-paced world of culinary innovation, the continuous operation sandwich grill plant has emerged as a game-changer. These state-of-the-art facilities are designed to cater to the ever-growing demand for quick and delicious sandwiches, offering a seamless production process that ensures efficiency and consistency. Let’s delve into the intricacies of these modern sandwich grill plants.

These plants are purpose-built to handle high volumes of sandwich production, often found in busy restaurants, food courts, and even mobile catering services. The heart of these operations lies in their ability to maintain a consistent output without compromising on quality. From the moment raw ingredients are processed to the final product being served, each step is meticulously managed to ensure the highest standards are met.

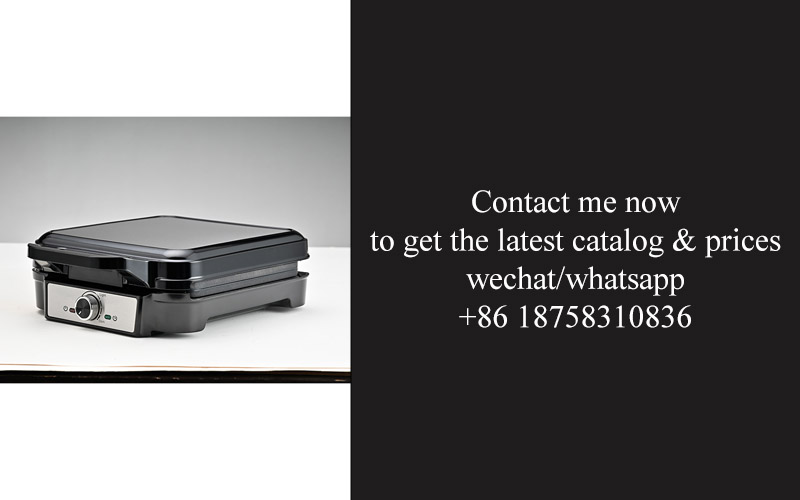

The core of a continuous operation sandwich grill plant is the grill itself. These grills are engineered to operate 24⁄7, capable of producing sandwiches at a rapid pace without any downtime. The design of these grills is both sophisticated and robust, featuring non-stick surfaces and precise heat control systems that ensure each sandwich is cooked to perfection.

One of the key advantages of these plants is the integration of automation. Robots and conveyors play a crucial role in the production process, handling tasks such as bread slicing, meat and cheese placement, and topping application. This not only increases speed but also reduces the potential for human error, leading to a higher quality end product.

The layout of a continuous operation sandwich grill plant is carefully designed to maximize efficiency. Ingredients are stored and accessed with ease, and the flow of production is optimized to minimize bottlenecks. The plant is often equipped with advanced inventory management systems that track the usage of ingredients in real-time, preventing waste and ensuring that supplies are always replenished promptly.

In terms of energy efficiency, these plants are a step above traditional sandwich preparation methods. Modern equipment is designed to consume less energy while maintaining high output. This not only reduces operational costs but also contributes to a smaller carbon footprint, aligning with the growing trend of sustainability in the food industry.

The market for continuous operation sandwich grill plants is witnessing rapid growth, driven by the increasing popularity of fast-casual dining. Consumers are seeking quick service with high-quality food, and these plants are perfectly tailored to meet these demands. The trend towards healthier eating habits is also a factor, as these plants can easily incorporate fresh ingredients and healthier options into their production lines.

Innovation in the sandwich grill industry is not limited to the hardware. Software solutions are also playing a pivotal role, with many plants utilizing cloud-based management systems that allow for remote monitoring and control. This means that operators can keep a close eye on production from any location, making adjustments as needed to ensure quality and efficiency.

The workforce in a continuous operation sandwich grill plant is also evolving. While automation has reduced the need for a large manual labor force, it has also created new opportunities for skilled technicians and engineers who are responsible for maintaining and upgrading the equipment. Training programs are often in place to ensure that staff can operate and maintain the sophisticated machinery effectively.

Safety is another crucial aspect of these plants. From ergonomic designs that reduce the risk of workplace injuries to strict hygiene protocols, safety is at the forefront of the operation. Regular inspections and maintenance schedules are in place to prevent accidents and ensure compliance with health and safety regulations.

Despite the numerous benefits, the continuous operation sandwich grill plant industry is not without its challenges. The initial investment in these plants can be significant, and the transition from traditional to automated methods can be daunting for some businesses. However, the long-term savings in labor, energy, and waste reduction often outweigh these initial costs.

Looking ahead, the future of continuous operation sandwich grill plants is bright. As technology continues to advance, we can expect to see even more sophisticated equipment that can handle an even wider variety of sandwich options. The integration of AI and machine learning could lead to even greater efficiency and personalized service for customers.

In conclusion, the continuous operation sandwich grill plant represents a leap forward in the world of sandwich production. Its ability to deliver high-quality sandwiches at an unprecedented pace, while remaining energy-efficient and environmentally friendly, positions it as a key player in the foodservice industry. As consumer demands evolve and technology advances, these plants are poised to become even more integral to the future of quick-service dining.

The evolution of sandwich grill technology has been a fascinating journey that reflects the changing landscape of culinary innovation and consumer preferences. From the humble origins of street food grills to the sophisticated, high-tech appliances found in today’s kitchens, the sandwich grill has come a long way.

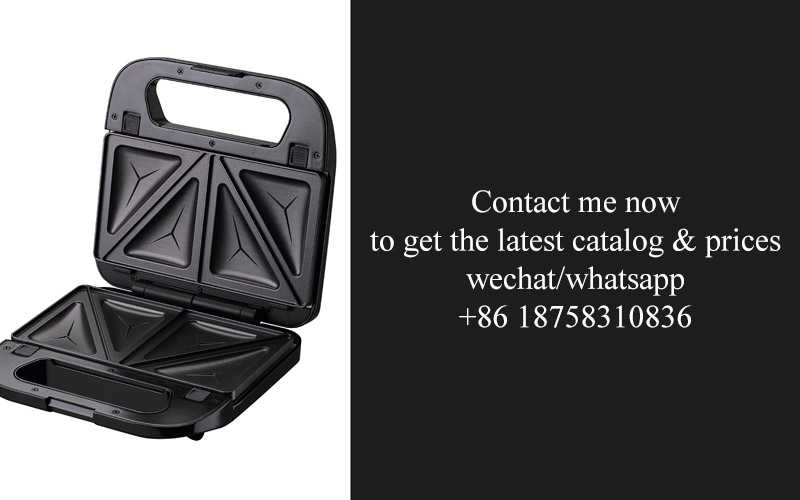

Once confined to the back alleys and bustling markets of the world, the sandwich grill was a simple tool for cooks to prepare quick and delicious sandwiches. These early grills were often made of cast iron or steel, with a flat surface that could be heated over a fire or with a heat source. The focus was on simplicity and functionality, allowing for the perfect char on the bread while keeping the fillings warm and toasty.

As the 20th century rolled in, sandwich grills began to transition from outdoor street vendors to indoor restaurants and homes. The technology started to evolve with the introduction of electric heat elements, which made the grilling process more controlled and less reliant on open flames. This shift not only improved safety but also allowed for consistent temperatures across the cooking surface.

The rise of convenience foods and the demand for speed in meal preparation spurred further advancements. Countertop sandwich makers with adjustable temperature controls emerged, enabling home cooks to achieve the perfect grilled sandwich with ease. These compact appliances often featured non-stick surfaces and removable parts for easy cleaning, making them a staple in many kitchens.

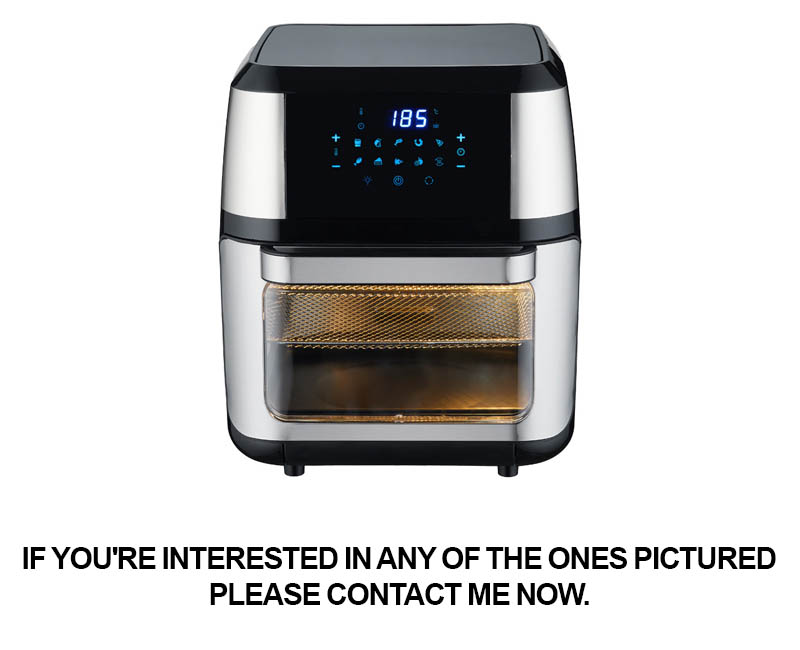

In the 21st century, sandwich grill technology has taken a significant leap forward. The integration of smart technology has brought a new level of control and customization to these appliances. Modern sandwich grills can now be programmed to maintain specific temperatures for different types of bread and fillings, ensuring the perfect balance of heat for each component.

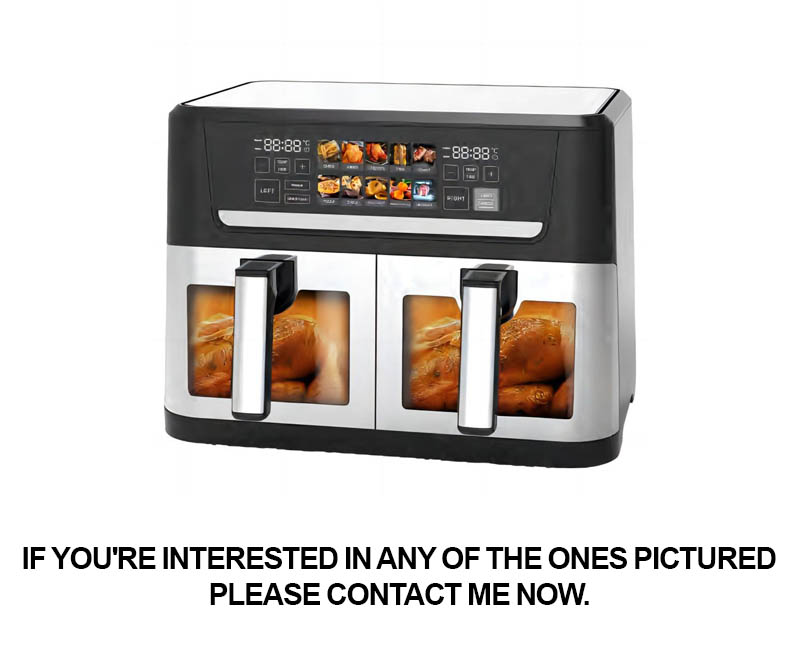

The design has also seen considerable changes. Traditional flat grills have given way to multi-level units that can cook multiple sandwiches simultaneously, catering to busy households and commercial kitchens alike. These advanced grills often come with non-stick, ceramic, or stone surfaces that are not only durable but also provide an even distribution of heat for superior cooking results.

Moreover, the trend towards health and wellness has influenced the evolution of sandwich grill technology. Many modern grills are equipped with features that help reduce the formation of harmful chemicals during cooking. Non-stick coatings have been refined to minimize the use of PFOAs, and some models now come with adjustable temperature settings that prevent overcooking and burning.

The materials used in sandwich grill construction have also improved. Stainless steel has become the preferred material for many high-end models due to its durability, heat retention, and resistance to corrosion. Some manufacturers have even started to experiment with new materials, such as copper and ceramic, which offer unique benefits like rapid heat transfer and a non-porous surface that is easy to clean.

In the realm of innovation, sandwich grill manufacturers have not been shy about incorporating features inspired by other cooking technologies. For example, some grills now come with induction heating, which is faster and more energy-efficient than traditional electric heating elements. Others have integrated infrared heating, which is known for its ability to cook food quickly and evenly.

The evolution of sandwich grill technology also reflects the increasing importance of user experience. Modern grills are not just about cooking; they are about convenience, ease of use, and aesthetic appeal. Many appliances now feature sleek designs, digital displays, and intuitive interfaces that make them not just practical but also a centerpiece in any kitchen.

As we look to the future, it’s clear that sandwich grill technology will continue to evolve. We can expect to see further integration of smart technology, with grills that can be controlled remotely via smartphones or tablets. There may also be advancements in materials and design that push the boundaries of what we consider a sandwich grill, potentially leading to new cooking methods and food experiences.

In summary, the journey of sandwich grill technology from a simple outdoor cooking tool to a sophisticated kitchen appliance has been driven by consumer demands, technological advancements, and a desire for convenience and quality. The evolution of the sandwich grill is a testament to how far we’ve come in the world of culinary technology and how far we can still go in the future.

The sandwich grill industry has seen a remarkable transformation over the years, with market dynamics evolving at a pace that reflects the changing tastes and demands of consumers. From humble beginnings to sophisticated technological advancements, the market has been shaped by several key factors.

Consumer Preferences ShiftingOne of the most significant dynamics in the sandwich grill industry is the shifting consumer preferences. Today’s consumers are more health-conscious than ever before, seeking options that offer convenience without compromising on nutritional value. This shift has spurred the development of low-fat, high-protein sandwiches, which are now a staple in many sandwich grill menus.

Market SegmentationThe market for sandwich grills has become increasingly segmented, catering to diverse customer bases. Fast-casual dining has grown in popularity, with customers seeking quality ingredients and quick service. At the same time, the rise of gourmet and artisanal sandwiches has opened up new opportunities for sandwich grill operators, who can target niche markets with specialized offerings.

Globalization and Cultural ExchangeGlobalization has played a pivotal role in shaping the sandwich grill industry. The exchange of culinary ideas and trends has led to a fusion of flavors, with international dishes becoming more accessible and popular. This has expanded the menu options for sandwich grill operators, allowing them to incorporate global influences into their offerings and attract a broader audience.

Competitive LandscapeThe competitive landscape in the sandwich grill industry is fierce, with a wide range of players vying for market share. Large fast-food chains, independent restaurants, and even home chefs have all contributed to the competition. To stand out, sandwich grill operators must differentiate themselves through unique offerings, exceptional service, and innovative marketing strategies.

Technological AdvancementsTechnological advancements have revolutionized the sandwich grill industry. Modern grills are equipped with features that enhance cooking efficiency, food quality, and safety. Automation has become a norm, with many sandwich grills now featuring programmable settings and self-cleaning functions. These technological improvements have not only streamlined operations but have also reduced labor costs for operators.

Health and Safety RegulationsHealth and safety regulations have become a crucial aspect of the sandwich grill industry. With increased public awareness of foodborne illnesses, operators must adhere to stringent hygiene standards. This has led to the adoption of new technologies and practices that ensure food safety throughout the preparation and cooking process.

Sustainability and Ethical SourcingConsumers are increasingly concerned about sustainability and ethical sourcing. This dynamic has influenced the sandwich grill industry, with operators seeking to source ingredients from local farmers and suppliers who prioritize environmental responsibility and fair labor practices. Sustainability initiatives not only resonate with environmentally conscious customers but can also provide a competitive edge.

Economic FactorsEconomic factors such as inflation and fluctuations in the cost of raw materials can significantly impact the sandwich grill industry. Operators must be vigilant about their cost structures and pricing strategies to remain profitable. Additionally, economic downturns can lead to changes in consumer spending habits, affecting the demand for high-priced gourmet sandwiches.

Digital TransformationThe advent of digital technology has transformed the way sandwich grill operators engage with customers. Online ordering, mobile apps, and social media marketing have become integral to the industry’s success. These digital tools enable operators to reach a wider audience, streamline service, and gather valuable customer data for targeted marketing.

Innovation and EntrepreneurshipInnovation and entrepreneurship continue to drive the sandwich grill industry forward. New startups are constantly emerging with fresh ideas and business models, challenging established players and bringing new concepts to the market. This dynamic competition fosters innovation, leading to continuous improvements in the quality and variety of sandwich grill offerings.

The sandwich grill industry’s market dynamics are complex, influenced by a multitude of factors that intersect to shape the current landscape. As the industry continues to evolve, operators must stay informed and adaptable, leveraging these dynamics to create a sustainable and profitable business.

In the world of commercial kitchen equipment, continuous operation sandwich grill plants have emerged as a game-changer. These specialized units are designed to handle high-volume production, ensuring consistent quality and efficiency. Let’s delve into the key features that make these plants stand out in the sandwich grill industry.

The heart of any continuous operation sandwich grill plant lies in its grilling system. These systems are engineered to maintain a constant temperature and heat distribution, which is crucial for producing uniform and perfectly cooked sandwiches. Advanced heating elements, often equipped with sensors, regulate the heat to ensure that every sandwich meets the desired level of crispiness and doneness.

Automated feeding systems are a cornerstone of continuous operation sandwich grill plants. These systems are designed to feed raw sandwich components into the grill in a precise and consistent manner. They can handle a variety of bread types, fillings, and condiments, and are often capable of switching between different sandwich recipes with minimal downtime.

Efficiency is paramount in the design of these plants. To achieve this, manufacturers have incorporated several features such as programmable control panels. These panels allow operators to set specific parameters for each sandwich type, including cooking time, temperature, and pressure. This level of customization ensures that the final product meets the brand’s standards and customer expectations.

One of the most significant features of continuous operation sandwich grill plants is their ability to handle high throughput. These units are built with robust construction, using heavy-duty components that can withstand constant use. The ability to process multiple sandwiches at once, sometimes up to 100 or more per hour, is made possible by conveyor belts or tracks that guide the sandwiches through the cooking process.

Sanitation and hygiene are critical in food service operations, and continuous operation sandwich grill plants are designed with these concerns in mind. Many models come with easy-to-clean surfaces and components that can be quickly disassembled for thorough sanitation. Features like self-cleaning programs and stainless steel construction help maintain a hygienic environment, reducing the risk of cross-contamination.

Energy efficiency is another key feature that sets these plants apart. Modern continuous operation sandwich grills are designed to minimize energy consumption without compromising on performance. Features like variable speed controls and energy-saving modes help reduce operational costs and lower the plant’s carbon footprint.

Safety is a top priority in the design of these plants. Emergency shut-off mechanisms are standard, ensuring that the equipment can be quickly stopped if there is a problem. Additionally, safety guards and interlocks protect operators from accidental contact with moving parts during operation.

The modular design of continuous operation sandwich grill plants allows for scalability. These units can be expanded or reconfigured to meet changing production needs or to integrate with other kitchen equipment. This flexibility makes them suitable for a wide range of commercial settings, from fast-food chains to large-scale catering operations.

In terms of maintenance, these plants are designed with serviceability in mind. Regular maintenance schedules are made easier with accessible components and clear instructions. This not only extends the life of the equipment but also minimizes downtime, ensuring a continuous flow of high-quality sandwiches.

The user interface is also a critical feature, with modern plants often featuring intuitive touchscreens or digital displays. These interfaces provide real-time monitoring and control, allowing operators to keep a close eye on the cooking process and make adjustments as needed.

Lastly, the integration capabilities of continuous operation sandwich grill plants are noteworthy. They can be seamlessly integrated with other systems such as POS (Point of Sale) systems, inventory management software, and even customer-facing display screens, creating a comprehensive solution for managing the entire sandwich production and sales process.

In summary, the key features of continuous operation sandwich grill plants encompass advanced grilling technology, automated feeding systems, programmable controls, high throughput, hygiene and sanitation features, energy efficiency, safety measures, scalability, easy maintenance, user-friendly interfaces, and comprehensive integration options. These features collectively make these plants a valuable asset for any business looking to streamline their sandwich production and meet the demands of a fast-paced market.

In the realm of sandwich grill technology, innovation has led to a series of design and functionality improvements that have transformed the way these grills operate. From advanced heating elements to user-friendly interfaces, here’s a look at some of the key innovations shaping the landscape:

Precision Heat Control SystemsModern sandwich grill plants are equipped with sophisticated heat control systems that allow for precise temperature regulation. These systems often include digital displays and programmable settings, enabling operators to set specific temperatures for different types of sandwiches. This precision not only ensures consistent cooking results but also reduces energy consumption by avoiding overheating.

Rapid Heat-Up TechnologyOne of the standout innovations in sandwich grill design is the ability to achieve high temperatures quickly. This is particularly beneficial in busy establishments where time is of the essence. Some grills now feature induction heating or advanced convection systems that cut down the time required to reach cooking temperature, ensuring that customers receive their orders promptly.

Multi-Zone Cooking SurfacesGrills with multi-zone cooking surfaces have become increasingly popular. These surfaces allow for different sections to be heated at varying temperatures, which is ideal for sandwiches that require a specific level of doneness on the bread or the filling. This feature is particularly useful for creating a variety of custom sandwiches to cater to diverse customer preferences.

Enhanced Non-Stick CoatingsThe non-stick coatings used in sandwich grill plants have seen significant advancements. Newer coatings are more durable and require less frequent maintenance, reducing downtime and labor costs. These coatings also prevent food from sticking, which is crucial for maintaining the integrity of the sandwich during the grilling process.

Integrated Cleaning SystemsCleaning is a crucial aspect of maintaining a sandwich grill plant, and innovative designs have made this process more efficient. Some grills now come with integrated cleaning systems that use steam or water sprays to clean the cooking surface without the need for harsh chemicals. This not only simplifies the cleaning process but also contributes to a healthier and safer kitchen environment.

Energy-Efficient DesignEnergy consumption is a major concern for businesses, and sandwich grill manufacturers have responded with energy-efficient designs. Grills that use less electricity not only reduce operational costs but also contribute to a greener footprint. Features like LED lighting, energy-saving heating elements, and automatic shut-off functions are now common in modern grill technology.

User-Friendly InterfacesThe user interfaces of sandwich grills have evolved to be more intuitive and user-friendly. Touchscreen controls, easy-to-read displays, and programmable recipes make it easier for operators to manage the grill without extensive training. This has also led to increased safety, as operators can quickly adjust settings without the risk of burns or accidents.

Customizable Work StationsInnovations in design have also led to the creation of customizable work stations. These stations can be tailored to the specific needs of the establishment, with additional features like toasting units, sandwich fillers, or cheese melters integrated seamlessly into the grill. This modular approach allows for a more flexible and efficient workflow.

Smart ConnectivityThe integration of smart technology has brought connectivity to sandwich grill plants. Grills can now be connected to kitchen management systems, allowing for real-time monitoring and control. This connectivity can help with inventory management, predictive maintenance, and even remote troubleshooting, ensuring minimal downtime.

Eco-Friendly MaterialsLastly, there’s a growing trend towards using eco-friendly materials in the construction of sandwich grill plants. From recycled stainless steel to biodegradable components, manufacturers are focusing on sustainability. These eco-friendly choices not only appeal to environmentally conscious consumers but also contribute to the overall green image of the business.

These innovations in design and functionality have collectively raised the bar in the sandwich grill industry, making these cooking stations more efficient, versatile, and user-friendly than ever before.

Continuous operation sandwich grill plants have revolutionized the food service industry, offering a game-changing approach to efficiency and productivity. These specialized facilities are designed to run seamlessly around the clock, providing a constant flow of freshly grilled sandwiches to meet the demands of busy cafes, restaurants, and even stadiums. Let’s delve into the pivotal role that continuous operation plays in enhancing these plants’ performance.

The ability to operate continuously is the backbone of these sandwich grill plants. Unlike traditional cooking methods that require breaks for cooling or maintenance, continuous operation ensures that the grill runs without interruption. This means that at any given moment, the equipment is cooking, which significantly reduces downtime and increases output.

Efficiency is paramount in the food industry, and continuous operation directly impacts it. With a steady stream of sandwiches being prepared, these plants can maintain a high throughput, which is crucial in environments where time is of the essence. For example, a stadium or an airport café needs to serve thousands of customers during peak hours, and a continuous operation sandwich grill plant can handle this demand with ease.

The design of these plants is tailored to maximize productivity. High-capacity grills, automated feeding systems, and intelligent control panels are just a few elements that contribute to their efficiency. These grills are often oversized to handle batches of sandwiches in rapid succession, ensuring that the production line never slows down.

Moreover, the integration of advanced technology allows for real-time monitoring and adjustments. Sensors can track temperature, humidity, and even the weight of the sandwiches, ensuring consistency and quality at every stage of the production process. This level of precision is not only time-saving but also cost-effective, as it minimizes waste and optimizes resource usage.

Productivity is not just about the quantity of sandwiches produced but also about the quality and variety. Continuous operation sandwich grill plants are equipped to cater to diverse preferences and dietary requirements. From classic ham and cheese to gourmet chicken and avocado, these plants can churn out a wide range of sandwiches at high speeds, keeping up with changing consumer trends.

The role of continuous operation in these plants is also evident in their energy efficiency. Modern sandwich grill plants are designed with energy-saving features that reduce power consumption without compromising performance. For instance, heat recovery systems can reuse the heat generated during the cooking process, cutting down on energy costs and environmental impact.

Furthermore, the design of these plants allows for minimal manual intervention. Automated systems can handle the loading and unloading of ingredients, the cooking process, and the packaging of the finished products. This not only speeds up production but also reduces the risk of human error, ensuring a high level of product quality and safety.

In terms of maintenance, continuous operation plants are built with durability in mind. The high-quality materials and robust construction ensure that the equipment can withstand constant use, reducing the frequency of repairs and breakdowns. This reliability is critical in maintaining a consistent output and minimizing production interruptions.

The scalability of continuous operation sandwich grill plants is another aspect that contributes to their productivity. These facilities can be designed to match the size of the operation, from small-scale catering businesses to large-scale commercial kitchens. This flexibility allows for easy expansion and adaptation to market needs.

In conclusion, the role of continuous operation in sandwich grill plants is multifaceted. It enhances efficiency by minimizing downtime, optimizes productivity through high-capacity and automated processes, and ensures consistent quality and variety in the products. With the ability to run 24⁄7, these plants have become a cornerstone of the modern food service industry, delivering fast, fresh, and delicious sandwiches with unparalleled efficiency and productivity.

In recent years, the sandwich grill industry has seen a surge in popularity, driven by market trends and evolving consumer preferences. Understanding these dynamics is crucial for players in the industry to stay competitive and meet the demands of their target audience.

The demand for convenience and speed has skyrocketed, leading to a shift in consumer preferences towards quick-service restaurants (QSRs) and fast-casual dining. This trend has been further fueled by the busy lifestyles of today’s consumers, who seek efficient and time-saving meal options. As a result, sandwich grills have become a staple in many foodservice establishments, offering a quick and satisfying meal solution.

Health consciousness has become a major driving force in the market. Consumers are increasingly seeking nutritious and balanced meals, leading to a rise in the popularity of healthier sandwich options. This shift has prompted manufacturers to develop grills that can accommodate a variety of ingredients, including whole grains, lean proteins, and fresh vegetables. The focus on health has also led to an increase in the use of non-stick surfaces and eco-friendly materials in sandwich grill designs.

Technology has played a significant role in shaping market trends. Smart grills with advanced features, such as adjustable temperature settings and timers, have become increasingly popular. These features allow operators to achieve consistent results and cater to a wider range of preferences. Additionally, the integration of connectivity options, such as Wi-Fi and Bluetooth, has enabled remote monitoring and control, enhancing operational efficiency.

The rise of social media and online reviews has had a profound impact on consumer preferences. Customers are more likely to try new sandwich grill offerings based on recommendations from peers and influencers. As a result, manufacturers and operators are focusing on creating unique and visually appealing sandwich options that can capture the attention of social media users. The use of high-quality images and engaging content has become a crucial aspect of marketing strategies in the industry.

The trend towards customization has also gained momentum. Consumers now expect to be able to tailor their meals to their specific preferences, whether it’s choosing between different types of bread, proteins, or toppings. This has led to the development of modular sandwich grill systems that can easily accommodate a variety of components. The ability to offer a personalized dining experience has become a key differentiator for businesses in the sandwich grill industry.

Sustainability has become a critical factor in consumer decision-making. As environmental concerns grow, more consumers are seeking out brands that prioritize sustainable practices. This includes the use of energy-efficient appliances, as well as the sourcing of locally produced and organic ingredients. Sandwich grill manufacturers are responding by offering eco-friendly models and promoting sustainable sourcing initiatives.

The rise of food trucks and pop-up restaurants has also influenced market trends. These mobile dining options offer a unique and convenient way to enjoy sandwiches, and they often incorporate innovative and portable sandwich grill technology. This has opened up new opportunities for businesses looking to expand their reach and appeal to a broader audience.

The integration of technology into the sandwich grill industry has not only improved efficiency and productivity but has also enhanced the overall dining experience. Touchscreen interfaces, interactive menus, and digital payment options have become common features in modern sandwich grill plants, making the process more intuitive and user-friendly for both operators and customers.

The rise of plant-based diets and alternative proteins has created a niche market within the sandwich grill industry. As more consumers adopt vegetarian and vegan lifestyles, there is a growing demand for sandwiches made with plant-based ingredients. This has prompted manufacturers to develop specialized grills that can handle these unique ingredients without compromising on flavor or texture.

In conclusion, the sandwich grill industry is shaped by a combination of convenience, health, technology, and sustainability. By understanding these market trends and consumer preferences, businesses can develop innovative products and services that cater to the evolving needs of their customers. Whether it’s through the use of advanced technology, the emphasis on health and sustainability, or the ability to offer personalized experiences, the future of the sandwich grill industry looks promising.

In the realm of continuous operation sandwich grill plants, several notable success stories have emerged, showcasing the impact of such facilities on the foodservice industry. These case studies highlight not only the technological advancements but also the strategic business decisions that contribute to their success.

At the forefront of these success stories is the “GrillBistro,” a sandwich grill plant that has revolutionized the fast-casual dining experience. Their continuous operation ensures a seamless flow of fresh, high-quality sandwiches, a key factor in their popularity. The plant’s design incorporates modular units that can be easily scaled, allowing GrillBistro to expand its menu and capacity without significant downtime.

The “QuickGrill Solutions” plant stands out for its innovative approach to energy efficiency. By utilizing a combination of solar panels and advanced heat recovery systems, the plant reduces its carbon footprint and operational costs. This commitment to sustainability has not only attracted environmentally conscious consumers but has also led to favorable branding and marketing opportunities.

The “Sandwich Station” plant has achieved success by focusing on the versatility of its grills. They have developed a range of sandwich grills that can handle different types of bread and fillings, from classic burgers to gourmet creations. This flexibility has allowed them to cater to a diverse clientele, from busy office workers to health-conscious diners.

In the case of “GrillEase,” a continuous operation plant, the key to their success lies in their efficient workflow and customer-centric design. The plant is equipped with state-of-the-art conveyor systems that ensure each sandwich is cooked to perfection, with minimal waste and maximum output. Their focus on customer satisfaction is evident in their quick service and consistent product quality.

“DelishGrill” has managed to carve a niche in the market by integrating their sandwich grill plant with a dedicated research and development team. This team constantly experiments with new flavors and cooking techniques, allowing the plant to introduce innovative products that keep customers coming back. Their continuous operation ensures that these new offerings are always available.

Another standout case is “SandwichPlex,” which has successfully integrated their continuous operation sandwich grill plant with a robust online ordering system. This allows customers to order sandwiches from the comfort of their homes, with delivery or pickup options. The plant’s ability to handle large volumes of orders efficiently has made it a favorite among busy families and individuals.

The “GrillHut” plant has thrived by partnering with local farmers and suppliers, ensuring that their ingredients are not only fresh but also locally sourced. This commitment to community and quality has earned them a loyal customer base and a reputation for excellence in the sandwich industry.

“GrillCafe” has taken a different approach by focusing on the gourmet segment of the market. Their continuous operation plant is equipped with high-end grills that can handle artisanal breads and specialty fillings. This niche strategy has allowed them to attract a premium clientele who are willing to pay a higher price for unique and high-quality sandwiches.

Each of these case studies demonstrates the importance of continuous operation in sandwich grill plants. From efficient workflow to innovative designs and strategic partnerships, these plants have found ways to stand out in a competitive industry. By examining their successes, other companies can learn valuable lessons about what it takes to run a successful continuous operation sandwich grill plant.

In the ever-evolving landscape of the sandwich grill industry, several challenges have emerged, alongside innovative solutions that are shaping the future of the market. From technological hurdles to consumer demands, here’s an exploration of the key challenges and the creative ways the industry is tackling them.

Maintaining Consistency in High-Volume ProductionOne of the biggest challenges in continuous operation sandwich grill plants is ensuring consistency in the quality of the sandwiches produced at a high volume. The key to overcoming this lies in precise control over the cooking process. Innovations such as programmable cooking cycles and automated monitoring systems have been introduced to maintain consistent heat distribution and cooking times, thus guaranteeing that every sandwich meets the highest quality standards.

Adapting to Diverse Consumer PreferencesThe consumer landscape is diverse, with preferences ranging from gourmet sandwiches to healthier options. Continuous operation plants must be adaptable to cater to this variety. Solutions include flexible production lines that can switch between different sandwich recipes with minimal downtime. Additionally, the use of modular components allows for easy upgrades and modifications to meet new trends and dietary requirements.

Energy Efficiency and SustainabilityEnergy consumption is a significant concern in any industrial setting. Continuous operation sandwich grill plants must find ways to reduce their environmental footprint while maintaining efficiency. Smart energy management systems and the integration of renewable energy sources, such as solar panels, are becoming increasingly common. These solutions not only cut costs but also contribute to a greener operation.

Health and Safety RegulationsCompliance with health and safety regulations is non-negotiable in the food industry. Continuous operation plants face the challenge of ensuring that all equipment and processes adhere to stringent standards. The implementation of advanced safety protocols, including regular maintenance checks and employee training programs, is crucial. Additionally, the use of materials that are food-safe and durable ensures that the equipment stands the test of time while maintaining hygiene.

Supply Chain ManagementThe complexity of the supply chain can pose significant challenges for continuous operation sandwich grill plants. Ensuring a steady supply of fresh ingredients is crucial, especially for products that require high turnover. Solutions include strategic partnerships with suppliers, just-in-time delivery systems, and inventory management software that predicts demand and adjusts orders accordingly.

Technological IntegrationThe integration of technology is vital for continuous operation. From automated cooking systems to customer relationship management (CRM) software, technology plays a pivotal role. However, integrating new technologies can be challenging. Continuous operation plants often invest in pilot programs and test kitchens to ensure that new tech solutions are compatible with existing systems and workflows.

Customer Experience and FeedbackThe customer experience is paramount in the sandwich industry. Continuous operation plants must be able to gather and act on customer feedback swiftly. This includes the use of digital platforms for online orders and reviews, as well as in-store feedback systems. The ability to quickly adapt to customer preferences based on real-time data is a competitive advantage.

Employee Training and RetentionSkilled labor is essential for the smooth operation of continuous operation sandwich grill plants. However, employee turnover can be high in the fast-paced food industry. To address this, plants are investing in comprehensive training programs that not only teach technical skills but also focus on soft skills and teamwork. Employee wellness initiatives and career development opportunities are also being introduced to improve retention rates.

Cost ManagementManaging costs is a constant challenge for any business, and the sandwich industry is no exception. Continuous operation plants must find ways to optimize their operations without compromising on quality. This involves strategic pricing, cost-effective sourcing, and efficient use of resources. The adoption of lean manufacturing principles and continuous improvement practices helps in reducing waste and increasing profitability.

Innovation in PackagingPackaging is not just about protecting the product; it’s also a tool for marketing and consumer convenience. Continuous operation plants are exploring innovative packaging solutions that are not only eco-friendly but also enhance the consumer experience. Biodegradable materials, single-use packaging that reduces waste, and innovative designs that make sandwiches easy to eat on-the-go are some of the trends shaping this aspect of the industry.

The challenge of maintaining a balance between quality, speed, and cost is at the heart of the sandwich grill industry. By addressing these challenges with innovative solutions, continuous operation plants are not only surviving but thriving in an increasingly competitive market.

In the evolving landscape of sandwich grill technology, several challenges and solutions have emerged to shape the industry’s trajectory. From adapting to consumer demands to overcoming technical hurdles, the industry is constantly seeking ways to improve. Here’s a look at some of the key challenges and the innovative solutions being implemented:

The need for increased speed and output without compromising quality has been a significant challenge for sandwich grill manufacturers. To meet this, many plants have invested in advanced automation systems that can handle high volumes while maintaining the integrity of the final product. These systems often include automated feeding mechanisms, precise temperature controls, and efficient cooling processes.

Energy efficiency remains a crucial concern, especially as the cost of utilities continues to rise. Plants have responded by integrating energy-saving features into their designs, such as smart heating elements that adjust to the sandwich’s cooking requirements, reducing unnecessary energy consumption.

Maintaining hygiene and safety standards is paramount in the food industry. Continuous operation sandwich grill plants have tackled this challenge by implementing rigorous cleaning protocols and using materials that are easy to sanitize. Some have even developed self-cleaning systems that can be activated between shifts or during downtime.

One of the biggest challenges is the integration of new technologies without disrupting the existing production line. Plants have addressed this by adopting modular designs that allow for the easy upgrade or replacement of components. This approach ensures that the plant can evolve with the latest innovations without a complete overhaul.

Another challenge is the variety of sandwich types and customization options that consumers demand. To cater to this, sandwich grill plants have developed versatile grilling systems that can accommodate different sizes and shapes of sandwiches, as well as various cooking temperatures and times.

The cost of equipment and maintenance is a significant factor for many businesses. To mitigate this, manufacturers have focused on creating more affordable yet durable equipment. They’ve also offered service packages that include maintenance and repairs, ensuring that the equipment remains operational and efficient over its lifespan.

The demand for eco-friendly practices has grown, and sandwich grill plants have responded by sourcing sustainable materials for their equipment and reducing waste in production. Some have even developed grills that use renewable energy sources, such as solar power, to further reduce their environmental footprint.

In terms of solutions, the industry has seen a rise in collaborative efforts between manufacturers and food service providers. By working closely together, they can tailor the equipment to the specific needs of the business, ensuring that the sandwich grill plant is not just a piece of machinery but a comprehensive solution to their operational challenges.

The need for flexibility in menu offerings has led to the development of grills that can handle a wide range of ingredients and cooking methods. This includes not just sandwiches but also wraps, burgers, and other handheld foods, allowing for a diverse and dynamic menu.

The integration of IoT (Internet of Things) technology has also been a game-changer. Plants are now able to monitor their equipment remotely, predict maintenance needs, and optimize production processes for better efficiency. This level of connectivity ensures that any issues can be addressed quickly, minimizing downtime.

Lastly, the industry faces the challenge of keeping up with changing health and safety regulations. To overcome this, sandwich grill plants are staying informed about the latest standards and incorporating them into their designs from the outset.

In summary, the challenges in the sandwich grill industry are numerous, but so are the innovative solutions being developed to address them. From automation and energy efficiency to sustainability and adaptability, the industry is poised for continued growth and improvement.