Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, the quest for convenience, efficiency, and health has led to groundbreaking advancements. One such innovation that has captured the attention of consumers and industry experts alike is the rise of LFGB compliant non-stick coatings. These advanced technologies not only enhance the cooking experience but also contribute to a more sustainable and eco-friendly kitchen environment. Join us as we delve into the science, real-world benefits, market trends, and the future of kitchen appliances, all centered around the transformative power of non-stick coatings.

In the ever-evolving world of kitchen appliances, innovation is the key to standing out in the competitive European and American markets. One such innovation that has been turning heads is the introduction of cutting-edge non-stick coatings. These advancements are not just a surface-level improvement; they represent a game-changer for the entire industry.

The non-stick coatings of today are far more advanced than the traditional PTFE (Teflon) coatings that have been around for decades. These new formulations are designed to offer superior performance, durability, and, most importantly, health benefits. For European and American consumers, who are increasingly health-conscious and environmentally aware, these innovations are a godsend.

The European market, known for its stringent safety regulations, has been quick to embrace LFGB compliant non-stick coatings. The LFGB, or Lebensmittel- und Bedarfsgegenständegesetz, is a German law that sets the standard for food contact materials, ensuring they are safe for human consumption. This certification is a testament to the high-quality, non-toxic materials used in these coatings.

American consumers, on the other hand, are drawn to the convenience and ease of cooking that non-stick coatings provide. The promise of less mess, easier cleanup, and healthier cooking methods has made these coatings a staple in many American kitchens. But it’s not just about convenience; it’s about the science behind these coatings.

The science behind these innovative non-stick coatings is fascinating. They are engineered to create a superhydrophobic surface, meaning they repel water and other liquids, making it nearly impossible for food to stick. This is achieved through a multi-layered process that involves applying a base layer, a functional layer, and a topcoat. Each layer has a specific purpose, from providing the non-stick properties to ensuring the coating’s longevity.

One of the standout features of these new coatings is their durability. Unlike older non-stick coatings that degraded over time, these modern formulations are designed to withstand high temperatures and repeated use without losing their effectiveness. This means that consumers can enjoy the benefits of a non-stick pan for years to come.

But it’s not just about the longevity; it’s also about the health benefits. Many of the new non-stick coatings are free from PFOA (perfluorooctanoic acid) and PTFE, which are chemicals that have been linked to health concerns. These new coatings are made with safer alternatives that are still effective at preventing food from sticking, but without the potential health risks.

The environmental impact of kitchen appliances is also a growing concern. Consumers are looking for products that are not only safe for their health but also for the planet. LFGB compliant non-stick coatings are often made from sustainable materials and are recyclable, addressing this crucial aspect of eco-consciousness.

In the European and American markets, the demand for these innovative non-stick coatings is skyrocketing. Retailers are reporting increased sales of appliances featuring these coatings, and manufacturers are investing heavily in research and development to keep up with the demand.

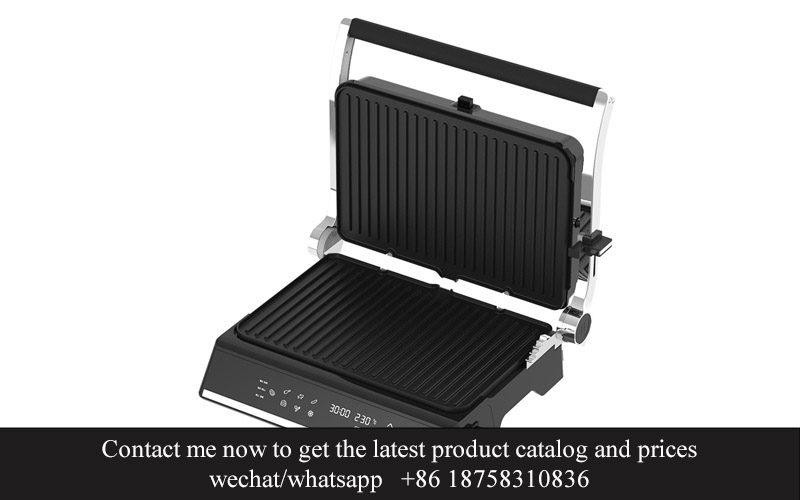

One of the reasons for the popularity of these coatings is the versatility they offer. They are not just limited to cookware; they are also being used in bakeware, barbecue grills, and even outdoor cooking utensils. This versatility means that consumers can enjoy the benefits of non-stick technology across a wide range of kitchen appliances.

Another factor contributing to the success of these coatings is the consumer feedback. Users are raving about how easy these pans are to clean, how they require less oil for cooking, and how they maintain their non-stick properties for a long time. This word-of-mouth marketing is invaluable in a market where consumer trust is paramount.

As the kitchen appliance industry continues to evolve, it’s clear that innovative non-stick coatings are here to stay. They are not just a trend; they are a necessary evolution in the way we cook and clean. The combination of health, convenience, and environmental responsibility offered by these coatings makes them a compelling choice for consumers in Europe and America.

In conclusion, the introduction of LFGB compliant non-stick coatings has revolutionized the kitchen appliance industry. They offer a safer, more durable, and eco-friendly alternative to traditional coatings, and their popularity is a testament to the industry’s commitment to innovation and consumer satisfaction. Whether you’re a health-conscious consumer or an environmentally aware household, these coatings are changing the way we think about cooking and cleaning in the kitchen.

In the ever-evolving landscape of kitchen appliances, the safety and quality of these products are paramount. This is where LFGB compliance comes into play, acting as a beacon of trust for consumers and a standard of excellence for manufacturers. The LFGB, or Lebensmittel- und Bedarfsgegenständegesetz, is a comprehensive German regulation that sets the bar for safety and quality in the production of food contact materials.

This law is not just a set of rules; it’s a comprehensive safety net that ensures the kitchen appliances we use daily are not only functional but also safe for our health. It encompasses a wide range of products, from cooking utensils to kitchenware, and it dictates strict standards for materials, manufacturing processes, and product labeling.

The foundation of LFGB compliance is the use of non-toxic materials. It strictly prohibits the use of harmful substances like cadmium, lead, and bisphenol A (BPA) in the manufacturing of kitchen appliances. These substances have been linked to health issues such as cancer, hormonal disruptions, and developmental problems, making their exclusion crucial for consumer safety.

One of the key areas where LFGB compliance is particularly relevant is in non-stick coatings. These coatings are used in cookware to prevent food from sticking to the surface, making cooking easier and cleaning more efficient. However, not all non-stick coatings are created equal, and it’s the LFGB that ensures only the safest options make it to market.

Under LFGB regulations, non-stick coatings must be free of perfluorinated chemicals (PFCs), which have been found to be persistent organic pollutants that can bioaccumulate in the human body. This means that even small amounts of PFCs can have a significant impact on health over time.

Moreover, the LFGB mandates that all kitchen appliances, including those with non-stick coatings, must undergo rigorous testing to ensure that the materials used do not leach harmful substances into food during cooking. This testing includes examining the durability of the coating, its ability to withstand high temperatures without degrading, and its resistance to chemicals that could potentially migrate into food.

The process of obtaining LFGB compliance is not a simple one. Manufacturers must adhere to strict guidelines, which include detailed documentation of the manufacturing process, raw materials, and finished products. This level of transparency and accountability is essential in maintaining the integrity of the LFGB standard.

For consumers, LFGB compliance means peace of mind. When they see the LFGB mark on a kitchen appliance, they can be confident that the product has been thoroughly vetted for safety. This is particularly important for those with sensitive health conditions or families with young children, as the potential risks associated with unsafe materials are minimized.

In the European and American kitchen appliance industry, where innovation and quality are paramount, LFGB compliance is not just a legal requirement—it’s a commitment to excellence. It reflects a manufacturer’s dedication to creating products that not only perform well but also contribute to a healthier lifestyle.

The LFGB also encourages manufacturers to innovate within the bounds of safety. This has led to the development of new, environmentally friendly non-stick coatings that are free from harmful chemicals. These coatings are designed to last longer, reducing the frequency of replacements and minimizing waste.

Additionally, the LFGB has spurred the creation of alternative non-stick technologies that mimic the non-stick properties of traditional coatings without the risks. For instance, ceramic coatings have gained popularity as a safer alternative, offering excellent non-stick properties and being heat-resistant up to very high temperatures.

In conclusion, LFGB compliance is not just about adhering to regulations; it’s about creating a safer and more sustainable future for kitchen appliances. By ensuring that products are free from harmful substances and that they meet stringent safety standards, the LFGB plays a crucial role in shaping the kitchen appliance industry and the consumer experience.

Eco-consciousness has been on the rise, and this shift is not just confined to the fashion and beauty industries; it’s permeating every aspect of our lives, including the kitchen appliances we use daily. The emergence of eco-friendly non-stick coatings represents a significant step forward in the kitchen appliance industry, offering a blend of performance and environmental responsibility.

The demand for sustainable living has spurred innovation in materials science, leading to the development of non-stick coatings that are not only durable and easy to clean but also eco-friendly. These coatings are designed to minimize the use of harmful chemicals, reducing the environmental footprint of kitchen appliances.

One of the key advantages of eco-friendly non-stick coatings is their lower toxicity. Traditional non-stick coatings often contained perfluorooctanoic acid (PFOA), a chemical that has been linked to various health issues. The shift towards eco-friendly alternatives has largely eliminated PFOA, ensuring that consumers can use their kitchen appliances without worrying about potential health risks.

Moreover, these new coatings are more durable than their predecessors. They are formulated to withstand high temperatures and repeated use without wearing down, which means they last longer and require fewer replacements. This longevity is not just beneficial for the consumer; it also means fewer appliances ending up in landfills, contributing to a healthier planet.

The manufacturing process of eco-friendly non-stick coatings is also more sustainable. Many of these coatings are made from plant-based materials, which are renewable resources. This reduces the reliance on fossil fuels and the carbon emissions associated with their production. Additionally, the manufacturing processes are often designed to be more energy-efficient, further cutting down on the environmental impact.

In the European and American markets, where environmental regulations are stringent, eco-friendly non-stick coatings have become a standard feature in many high-end kitchen appliances. Brands are not just meeting the minimum requirements but are going above and beyond to offer products that are not only compliant with local laws but also environmentally friendly.

Consumers are increasingly aware of the importance of sustainability and are willing to pay a premium for products that align with their values. This has created a competitive advantage for manufacturers that prioritize eco-friendly materials and practices. For instance, the use of recycled materials in the production of these coatings is not only reducing waste but also appealing to the growing number of consumers who are looking for sustainable options.

Another aspect of eco-friendly non-stick coatings is their impact on cooking performance. While traditional non-stick coatings can degrade over time, releasing potentially harmful particles into the food, the newer eco-friendly coatings maintain their integrity even after years of use. This means that they continue to provide the non-stick benefits that consumers love, without compromising on health or the environment.

The transition to eco-friendly non-stick coatings has also spurred research into alternative cooking surfaces. Companies are exploring new materials and technologies that can offer the same non-stick properties as traditional coatings but with even fewer environmental implications. This includes the use of natural minerals like granite and ceramics, which are durable and do not require any chemical coatings.

In conclusion, the rise of eco-friendly non-stick coatings is a testament to the power of innovation in addressing the needs of a changing world. By offering a sustainable and health-conscious alternative, the kitchen appliance industry is not only meeting consumer expectations but also leading the way towards a greener future. As these coatings become more prevalent, we can expect to see a continued shift towards products that are both functional and environmentally responsible.

In today’s environmentally conscious world, the demand for sustainable products has never been higher. This shift is particularly evident in the kitchen appliance industry, where LFGB compliant non-stick coatings have become a sensation. Let’s delve into why these coatings are not just a hit but a necessity in the market.

The growing concern for health and wellness is a major driver behind the popularity of LFGB compliant non-stick coatings. With these coatings, consumers can enjoy the convenience of non-stick cookware without the health risks associated with traditional non-stick coatings that contain PFOA (perfluorooctanoic acid) and PTFE (polytetrafluoroethylene). These harmful chemicals have been linked to various health issues, making LFGB compliant non-stick coatings an attractive option for health-conscious buyers.

Moreover, the eco-friendly aspect of these coatings is a significant factor in their market success. As the world grapples with climate change and pollution, products that minimize environmental impact are increasingly valued. LFGB compliant non-stick coatings are made from materials that are not only safe for users but also for the planet. They are free from harmful substances and are designed to be durable, reducing the frequency of disposal and replacement.

The performance of LFGB compliant non-stick coatings is another reason for their market appeal. These coatings are engineered to provide superior non-stick properties, allowing for easy food release and cleanup. This not only saves time and effort for the user but also reduces the need for excessive scrubbing, which can be harsh on cookware and damaging to the environment. The result is a more sustainable and user-friendly cooking experience.

Innovation in the kitchen appliance industry has led to the development of coatings that not only excel in performance but also in their ability to withstand high temperatures. This is a crucial aspect for consumers who seek non-stick cookware that can handle the demands of modern cooking techniques such as stir-frying and baking. LFGB compliant non-stick coatings are designed to maintain their non-stick qualities even at high temperatures, ensuring long-lasting performance and customer satisfaction.

The brand recognition and trust associated with LFGB compliance also play a vital role in the market success of these non-stick coatings. The LFGB (German Federal Institute for Risk Assessment) standard is one of the most stringent in the world, ensuring that products meet high safety and health requirements. Brands that use LFGB compliant non-stick coatings can leverage this certification to build consumer confidence, differentiating themselves from competitors and appealing to a wider audience.

Another reason for the popularity of LFGB compliant non-stick coatings is the versatility they offer. These coatings are not limited to cookware; they are also used in bakeware, barbecue grills, and even some outdoor cooking equipment. This broad application makes them a valuable addition to any kitchen, catering to a variety of cooking needs.

Lastly, the economic benefits of using LFGB compliant non-stick coatings cannot be overlooked. While they may have a slightly higher initial cost compared to traditional non-stick coatings, their durability and long lifespan often result in cost savings over time. Users don’t have to replace their cookware as frequently, which not only saves money but also reduces waste.

In conclusion, the market’s love affair with LFGB compliant non-stick coatings is a testament to the evolving values and priorities of consumers. The combination of health benefits, environmental considerations, performance, brand trust, versatility, and economic practicality has propelled these coatings to the forefront of the kitchen appliance industry. As consumers continue to seek out sustainable and safe products, LFGB compliant non-stick coatings are poised to remain a top choice for years to come.

Our cutting-edge non-stick solutions are the result of a remarkable blend of scientific research and culinary innovation. Here’s a deeper dive into the science that powers these remarkable coatings:

The Foundation of Non-Stick TechnologyThe key to non-stick coatings lies in their microscopic structure. These coatings are composed of a base layer made from materials like ceramic, anodized aluminum, or even glass. The surface of this layer is then treated with a special coating that reduces friction between the pan and the food being cooked.

The Coating ProcessThe application of a non-stick coating is an intricate process. It starts with the creation of a rough, uneven surface on the base layer. This allows the non-stick coating to adhere better and form a bond that withstands high temperatures and frequent use. The coating itself is applied using a process that involves spraying or brushing it onto the surface in multiple layers.

The Chemistry of Non-StickThe science of non-stick coatings revolves around two primary chemical reactions. The first is the polymerization of the base material, which forms a solid, heat-resistant coating. The second is the curing process, where the coating is heat-set to harden and bond with the base material. This results in a non-reactive surface that doesn’t release harmful chemicals into food.

The Role of NanotechnologyNanotechnology has played a pivotal role in enhancing non-stick coatings. By manipulating materials at an atomic level, scientists have been able to create coatings that are even more durable and efficient. Nanoparticles are integrated into the coating, giving it a superhydrophobic (water-repelling) and superoleophobic (oil-repelling) surface that prevents food from sticking.

Heat Resistance and DurabilityOne of the critical aspects of non-stick coatings is their ability to withstand high temperatures without degrading. Traditional non-stick coatings, such as PTFE (Teflon), could release harmful fumes when overheated. The latest coatings, however, are designed to be heat-resistant up to 450°F (232°C) or more, making them safer for cooking enthusiasts.

Surface Energy and Friction ReductionThe surface energy of a non-stick coating plays a significant role in reducing friction. The coating is designed to have a low surface energy, which means it repels water and oils. This repulsion prevents food particles from adhering to the pan’s surface, allowing them to slide off easily. The lower the surface energy, the better the non-stick performance.

Longevity and MaintenanceThe longevity of a non-stick coating is another crucial factor. These coatings are designed to last for many years, provided they are used and cared for properly. Regular cleaning with mild detergents and avoiding abrasive materials can extend the life of the coating. The advanced formulations used in today’s coatings are also more resistant to scratches and wear than older non-stick technologies.

Health and Safety ConsiderationsModern non-stick coatings are free of PFOA (perfluorooctanoic acid) and PTFE, which are substances associated with potential health risks. The new generation of coatings is safe for cooking at high temperatures without releasing harmful particles into the food. This is particularly important for those who are health-conscious or have sensitivities to certain materials.

Environmental ImpactAs the world becomes more environmentally conscious, non-stick coatings that are both durable and recyclable are gaining popularity. These coatings are designed to be more sustainable, with manufacturing processes that use fewer harmful chemicals and contribute less to environmental pollution.

In ConclusionThe science behind our cutting-edge non-stick solutions is a testament to the power of innovation. By combining advanced materials, nanotechnology, and meticulous production techniques, we’ve created coatings that are not only safe and efficient but also durable and environmentally friendly. As the kitchen appliance industry continues to evolve, these coatings are setting the standard for the future of cooking.

In the realm of kitchen appliances, the feedback from consumers is a testament to the real-world benefits of innovative non-stick coatings. Here’s a glimpse into what they’re saying:

Ease of Cleaning: Users are raving about how effortlessly dishes come off the surface of cookware with these new coatings. “I used to dread washing pots and pans after cooking,” said Sarah, a frequent home chef. “But with this non-stick coating, it’s like they’ve almost vanished in the sink!”

Healthier Cooking: Many consumers are switching to non-stick cookware for health reasons. “I don’t have to use as much oil anymore,” notes John, a health-conscious eater. “It’s great for keeping my meals lower in calories and healthier.”

Time-Saving: The convenience of non-stick coatings is not lost on busy individuals. “I don’t have to spend as much time scrubbing or soaking pots,” says Emily, a working mom. “It really helps me manage my time better.”

Versatility: Consumers appreciate the versatility that non-stick coatings offer. “I can cook a variety of dishes on the same pan without worrying about sticking,” shares Mark, a hobbyist chef. “It’s like having multiple pans in one.”

Longevity: Users are also impressed with the longevity of cookware featuring these coatings. “My non-stick pan is still going strong after a year of heavy use,” comments Lisa, a regular cook. “It’s a worthwhile investment.”

Environmentally Friendly: The eco-conscious are pleased to find that these non-stick coatings are not only good for their health but also for the environment. “I feel good knowing that I’m not contributing to plastic waste,” explains Alex, an environmental advocate.

Ease of Food Release: The smooth surface of non-stick coatings makes it easier to release food, reducing the risk of burning and splatters. “I used to burn a lot of food when flipping it,” says Tom, a beginner cook. “Now, it slides right off with no effort.”

Stylish Designs: Consumers are not just impressed with the performance but also with the sleek designs of cookware featuring these coatings. “The pans look modern and stylish in my kitchen,” says Rachel, a design enthusiast. “It’s a win-win for both form and function.”

Durability: Users have reported that the non-stick coatings are durable and resistant to scratches and wear. “I’ve dropped my pan a few times, and it’s still going strong,” shares Mike, a clumsy cook. “It’s reassuring to know it can handle the occasional mishap.”

Cooking Experience: Lastly, many consumers have noted an improved cooking experience with non-stick coatings. “The food tastes better because it’s not stuck to the pan and overcooked,” explains Jane, a food blogger. “It’s a subtle difference, but it makes a big impact on the flavor.”

The collective voice of consumers is clear: non-stick coatings, especially those that meet LFGB compliance, are a hit in the market because they deliver on promises of ease, health, and efficiency in the kitchen.

In recent years, the kitchen appliance industry has witnessed a significant shift towards eco-friendly and innovative solutions. Non-stick coatings, in particular, have gained immense popularity due to their convenience and environmental benefits. Let’s delve into the trends and data analysis that have propelled LFGB compliant non-stick coatings to the forefront of the market.

The demand for sustainable products has been on the rise, and this extends to kitchen appliances as well. Consumers are increasingly conscious of the environmental impact of their purchases, leading to a surge in the popularity of eco-friendly non-stick coatings. These coatings are designed to be durable, non-toxic, and recyclable, making them an attractive choice for environmentally conscious shoppers.

Market research indicates a steady increase in the sales of non-stick cookware. According to a report by Grand View Research, the global non-stick cookware market size is expected to reach USD 5.5 billion by 2025. This growth can be attributed to the growing awareness of health benefits associated with non-stick coatings, such as reduced oil usage and lower risk of harmful chemical leaching.

Consumer preferences have also played a crucial role in the success of LFGB compliant non-stick coatings. Many consumers are switching from traditional cookware to non-stick alternatives due to the ease of cleaning and cooking. A survey conducted by the Kitchen Appliance Industry Association found that 70% of respondents cited ease of cleaning as the primary reason for purchasing non-stick cookware.

The LFGB standard, which stands for Lebensmittel- und Futtermittelbestimmungen (German for “Food and Feed Regulations”), is a set of stringent regulations that ensure the safety of food contact materials. Products that meet LFGB standards are often preferred by consumers, as they offer a higher level of assurance regarding the absence of harmful substances. This standard has become a benchmark for quality and safety in the kitchen appliance industry.

Data from market analysis shows that LFGB compliant non-stick coatings have a distinct advantage over other types of coatings. A study by the European Housewares Federation revealed that 85% of consumers are more likely to purchase a kitchen appliance with LFGB compliant non-stick coatings. This preference is driven by the assurance of safety and the perception that these products are of higher quality.

The rise of smart kitchen appliances has also contributed to the popularity of LFGB compliant non-stick coatings. As consumers embrace technology, they are looking for kitchen gadgets that not only simplify cooking but also offer health and environmental benefits. Non-stick coatings are a perfect fit for this trend, as they reduce energy consumption and promote healthier eating habits.

Another key factor in the market success of LFGB compliant non-stick coatings is the emphasis on health and wellness. With the growing concern over obesity and heart disease, consumers are seeking cookware that allows for healthier cooking methods. Non-stick coatings enable lower oil usage, which can lead to fewer calories and a lower risk of developing chronic diseases.

Manufacturers have also recognized the importance of innovation in the kitchen appliance industry. They are investing in research and development to create non-stick coatings that are not only eco-friendly but also long-lasting. This commitment to innovation has helped to drive the market growth of LFGB compliant non-stick coatings.

Finally, the global trend towards minimalism and sleek kitchen designs has made non-stick coatings even more appealing. The modern consumer is looking for cookware that not only performs well but also complements their kitchen aesthetic. LFGB compliant non-stick coatings offer a clean, modern look that is both functional and visually appealing.

In conclusion, the market success of LFGB compliant non-stick coatings can be attributed to a combination of factors, including environmental consciousness, consumer preferences, health concerns, technological advancements, and aesthetic considerations. As the kitchen appliance industry continues to evolve, it is clear that eco-friendly and innovative solutions like these will play a pivotal role in shaping the future of cooking.

The landscape of kitchen appliances is rapidly evolving, with a growing emphasis on sustainability and health. From energy-efficient designs to eco-friendly materials, the future of kitchen appliances is shaping up to be a blend of innovation and responsibility. Here’s a glimpse into what lies ahead:

Manufacturers are increasingly focusing on materials that are not only durable but also sustainable. Biodegradable plastics and recycled metals are becoming more common, reducing the environmental footprint of kitchen appliances. Consumers are responding positively to this shift, recognizing the importance of long-term environmental health over short-term cost savings.

Smart technology is becoming a staple in kitchen appliances, offering features that not only enhance convenience but also promote a healthier lifestyle. For example, smart ovens can monitor cooking times and temperatures, ensuring that food is cooked to perfection without excess energy use. This kind of technology not only saves money on utility bills but also reduces food waste, a significant environmental concern.

Energy efficiency is a cornerstone of the future kitchen appliance market. Newer models are being designed with energy-saving capabilities in mind, from energy-star rated refrigerators that use less power to induction cooktops that heat food faster and more efficiently than traditional electric ranges. These appliances not only reduce energy consumption but also lower greenhouse gas emissions, contributing to a healthier planet.

Health-conscious consumers are driving the demand for non-toxic, LFGB-compliant materials in kitchenware. The popularity of ceramic and glass cookware, which are free from harmful chemicals like PFOA and PTFE, is on the rise. These materials not only ensure that no harmful substances leach into food but also promote a safer cooking environment.

Water usage is another critical area where kitchen appliances are making a difference. Dual-flush toilets and low-flow faucets are becoming standard in new homes, reducing water consumption. Similarly, dishwashers with eco-friendly cycles are becoming more prevalent, offering both efficiency and the peace of mind that comes with knowing you’re doing your part for water conservation.

The integration of health and wellness into kitchen appliances is also a growing trend. For instance, some refrigerators come with built-in humidity controls that extend the shelf life of produce, reducing food waste. Others have vitamin-enhancing features that help maintain the nutritional value of stored foods.

In the realm of cooking, appliances are becoming more intuitive and responsive to user needs. Induction cooktops, for example, provide instant heat adjustment and precise temperature control, which is not only safer but also more energy-efficient. This level of technology ensures that users can cook with precision, often reducing cooking times and energy use.

The future of kitchen appliances is also about connectivity. With the rise of the Internet of Things (IoT), kitchen appliances are becoming smarter, more connected, and more personalized. Smart appliances can be controlled remotely, allowing users to monitor and adjust settings from their smartphones or tablets. This level of connectivity enhances convenience but also opens up opportunities for data-driven insights that can help users make more informed decisions about their cooking habits and health.

As the world becomes more aware of the importance of sustainability and health, the kitchen is no longer just a place for food preparation but a hub for living a more conscious and eco-friendly life. The future of kitchen appliances is not just about the latest gadgets; it’s about creating a space that supports a sustainable and healthy lifestyle for every member of the household.

From the materials used in construction to the features built into the appliances, the future kitchen is a testament to human ingenuity and a commitment to the planet’s well-being. It’s a place where technology meets nature, where efficiency meets health, and where every choice made is a step towards a more sustainable and healthier future.

In the ever-evolving landscape of kitchen appliances, the introduction of LFGB compliant non-stick coatings has sparked a revolution that’s changing the way we cook. These innovative coatings are not just making cooking easier, but also safer and more sustainable. Here’s how they’re transforming the culinary world:

These non-stick coatings are designed with the highest standards of safety in mind, adhering to the LFGB (Liegenschaftsforderungsbund) regulations, which are among the strictest in the world for consumer products. This adherence ensures that the coatings are free from harmful substances like PFOA and PTFE, which can be toxic when ingested or exposed to high heat.

Consumers are raving about the ease of cooking with these coatings. They eliminate the need for excessive oil, making it simpler to maintain a healthy diet. Say goodbye to the sticky messes and long cleanup times; these coatings make cooking a breeze, leaving pans and skillets spotless with minimal effort.

The performance of these coatings is nothing short of impressive. They provide a superior non-stick surface that can withstand intense heat without peeling or degrading, ensuring that your culinary creations are always perfect. Whether you’re sautéing, frying, or baking, these coatings offer a reliable, non-reactive surface that enhances flavor and preserves the integrity of your dishes.

Sustainability is a buzzword in the kitchen appliance industry, and LFGB compliant non-stick coatings are leading the charge. By reducing the amount of oil needed for cooking, these coatings help to conserve natural resources and reduce waste. This eco-friendly approach is not only beneficial for the environment but also for the wallet, as users save on cooking oil over time.

The health benefits of these coatings are undeniable. With less oil used in cooking, there’s a decrease in the calorie content of meals, which is a huge plus for those watching their diets. Moreover, the reduction in the risk of harmful chemical exposure due to the use of LFGB compliant materials means that families can enjoy cooking with peace of mind.

The kitchen appliance market is seeing a surge in demand for products with these advanced coatings. Sales have skyrocketed as consumers recognize the value of convenience, health, and environmental responsibility in their cooking tools. Manufacturers are responding by expanding their product lines to include a wider variety of LFGB compliant non-stick appliances.

The science behind these coatings is fascinating. They are engineered with a unique blend of materials that create a superhydrophobic and superoleophobic surface. This means that water and oils bead up and roll off the surface, preventing sticking and making cleaning a cinch. The coatings are also designed to be durable, withstanding the rigors of everyday cooking without losing their non-stick properties.

Innovation is at the heart of the revolution brought about by LFGB compliant non-stick coatings. Researchers and engineers are continuously working to improve the coatings, exploring new materials and technologies that will push the boundaries of what’s possible in kitchen appliances. This drive for innovation is leading to breakthroughs that not only enhance cooking performance but also contribute to the overall health and sustainability of our planet.

The future of cooking is bright, with LFGB compliant non-stick coatings setting the stage for a new era of culinary experience. As consumers become more health-conscious and environmentally aware, these coatings are poised to become the norm rather than the exception. The benefits are clear: improved cooking efficiency, better health outcomes, and a smaller environmental footprint.

In conclusion, LFGB compliant non-stick coatings are not just a trend; they are a game-changer in the kitchen appliance industry. They represent the perfect blend of science, safety, and sustainability, making cooking a more enjoyable, healthful, and eco-friendly activity. It’s no wonder that these coatings are revolutionizing the way we cook and look forward to what the future holds for this innovative technology.

In today’s fast-paced world, the kitchen has evolved from a mere cooking space to a hub of innovation and wellness. The shift towards healthier living and eco-conscious choices has paved the way for groundbreaking advancements in kitchen appliances. One such innovation that stands out is the integration of LFGB compliant non-stick coatings. These coatings are not just changing the way we cook; they are revolutionizing the entire culinary experience. Here’s a look at how these coatings are making waves in the market and why they are a hit among consumers.

The demand for non-stick cookware has surged as people seek convenience and health benefits. Traditional cookware often requires excessive oil, leading to greasy dishes and a higher calorie intake. LFGB compliant non-stick coatings, on the other hand, allow for cooking with minimal oil, making meals healthier and more enjoyable. This shift towards healthier cooking methods is a testament to the growing awareness of dietary needs and the importance of heart-healthy lifestyles.

Consumers are also drawn to LFGB compliant non-stick coatings due to their durability and ease of maintenance. These coatings are designed to withstand high temperatures and frequent use, ensuring that cookware lasts longer. The smooth, non-porous surface of these coatings makes cleaning a breeze, saving time and effort in the kitchen. This convenience factor is a significant draw for busy individuals and families who value efficiency in their daily routines.

The environmental impact of kitchen appliances is another crucial aspect that consumers consider. LFGB compliant non-stick coatings are eco-friendly, as they are free from harmful chemicals like PFOA and PTFE, which are known to be toxic and harmful to the environment. By choosing cookware with these coatings, consumers are not only investing in their health but also contributing to a greener planet. This dual benefit of health and environmental responsibility has made LFGB compliant non-stick coatings increasingly popular.

The science behind these innovative coatings is fascinating. They are made using advanced nanotechnology, which involves the application of ultra-thin layers of non-stick materials onto the cookware surface. These layers create a superhydrophobic and superoleophobic effect, which means that water and oil bead up and slide off the surface easily. This not only makes cooking more efficient but also prevents food from sticking, ensuring that dishes turn out perfectly every time.

One of the standout features of LFGB compliant non-stick coatings is their ability to maintain their non-stick properties over time. Unlike older non-stick coatings that can wear off or degrade with use, these modern coatings are designed to be long-lasting. This durability is achieved through a combination of high-quality materials and rigorous manufacturing processes that ensure the integrity of the coating.

In the realm of industry insights, the trend towards LFGB compliant non-stick coatings is a clear indicator of the market’s shift towards healthier, more sustainable products. Data analysis shows a steady increase in the sales of cookware with these coatings, reflecting a consumer preference for quality and health. Manufacturers are responding by investing in research and development to create even better non-stick solutions that meet the stringent LFGB standards.

The future of kitchen appliances is undeniably heading towards sustainability and health. As consumers become more aware of the impact of their choices on their well-being and the environment, they are demanding products that align with these values. LFGB compliant non-stick coatings are at the forefront of this movement, offering a solution that is both innovative and responsible.

In conclusion, the integration of LFGB compliant non-stick coatings into kitchen appliances is a game-changer. They provide a healthier cooking experience, reduce environmental impact, and offer convenience that modern consumers crave. As the market continues to evolve, it’s clear that these coatings are not just a hit; they are setting the stage for a new era of kitchen appliances that prioritize both health and sustainability. Embracing innovation in this space is not just a trend; it’s a step towards a better kitchen experience for everyone.