Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving culinary landscape, the quest for efficiency and quality in kitchen equipment remains a top priority for chefs and restaurant owners alike. Enter the NSF Approved Commercial Sandwich Press, a beacon of innovation that promises to transform the way sandwiches are made, served, and savored. With its array of features and benefits, this cutting-edge appliance is not just a tool; it’s a game-changer that’s already generating buzz in the market. Let’s delve into the world of this sandwich-making marvel and explore why it’s poised to become an indispensable part of modern commercial kitchens.

Ah, there’s something exciting brewing in the culinary world, and it’s not just the aroma of freshly toasted bread. We’re talking about the latest innovation to hit commercial kitchens everywhere: the NSF Approved Commercial Sandwich Press. This isn’t just any sandwich press; it’s a game-changer that’s poised to revolutionize the way we think about fast food and quick-service restaurants.

Imagine a kitchen where the pressure is on, and time is of the essence. In these bustling environments, every second counts, and every detail matters. That’s where this sandwich press steps in, a sleek, efficient tool that promises to elevate the art of sandwich-making to new heights. With its NSF approval, it’s not just a gadget; it’s a guarantee of quality and safety that restaurateurs and chefs can rely on.

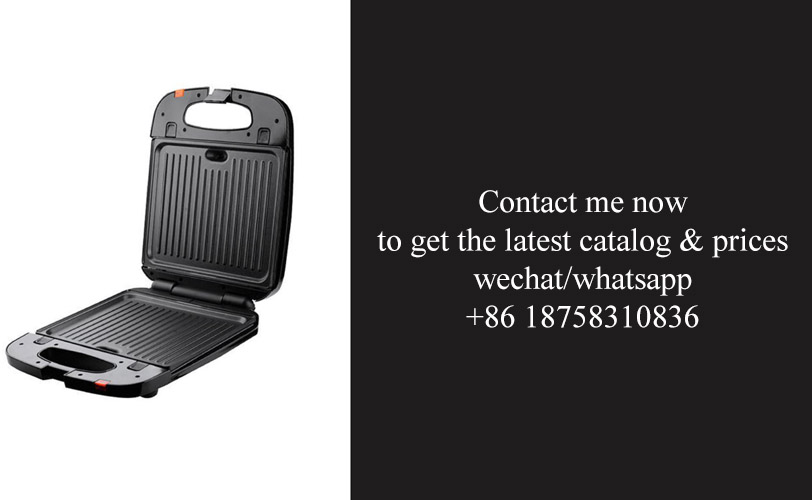

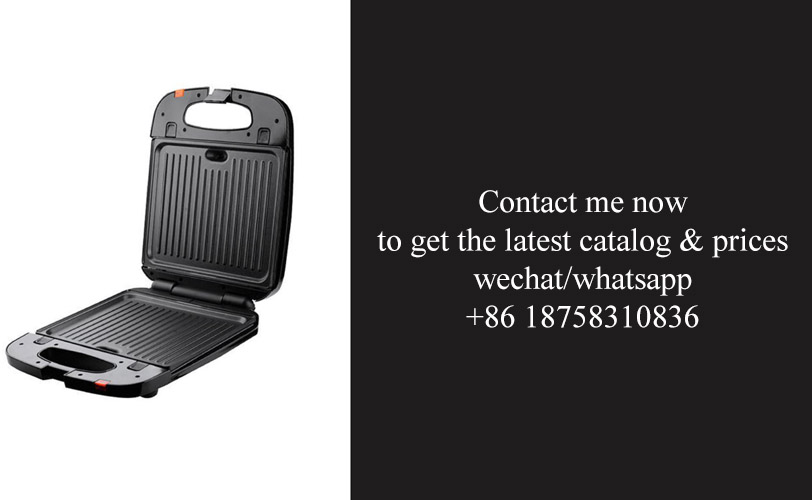

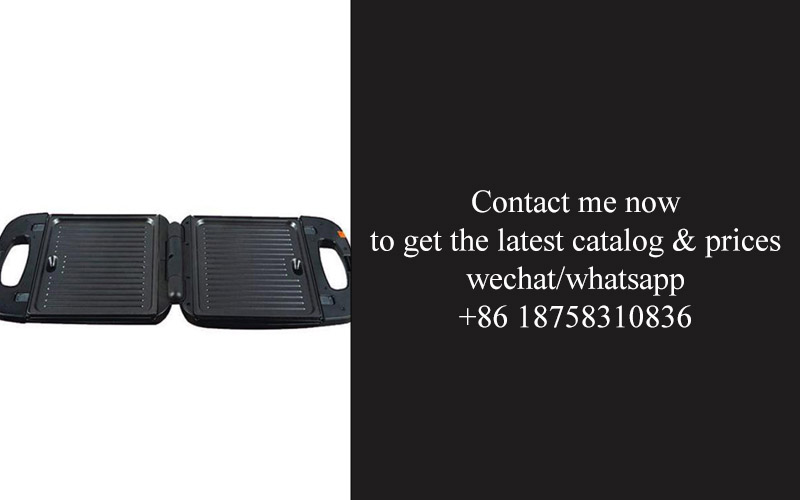

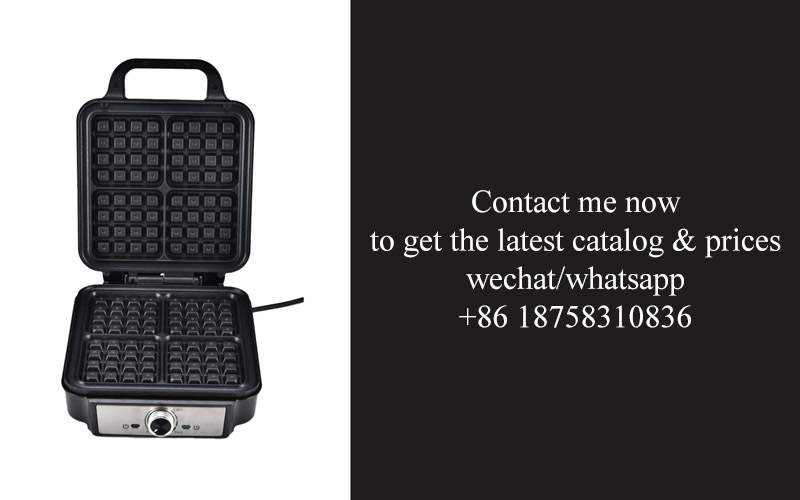

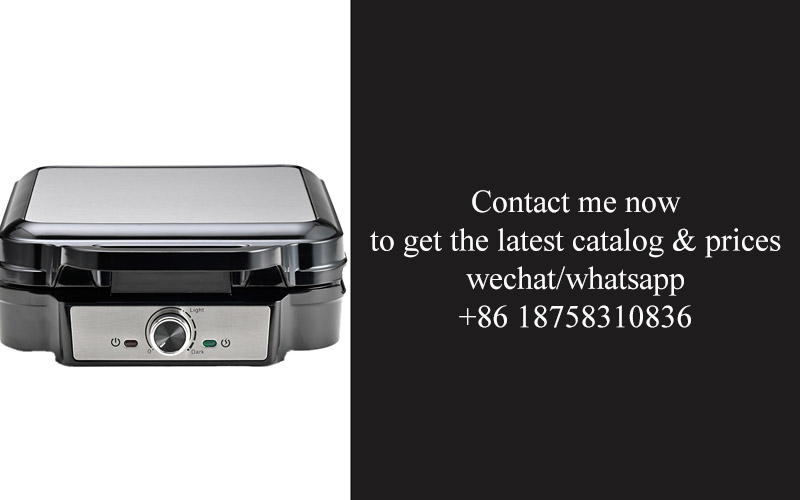

The design of the NSF Approved Commercial Sandwich Press is both stunning and functional. It boasts a modern aesthetic that complements any kitchen decor, with a sturdy build that can withstand the rigors of a busy kitchen. The press is crafted with precision, ensuring that each sandwich is pressed to perfection, with a golden-brown crust that’s crispy on the outside and tender on the inside.

But what truly sets this sandwich press apart is its innovative features. The heat distribution is unparalleled, with an advanced heating element that ensures even cooking across the entire surface of the sandwich. No more soggy bread or cold fillings; every bite is a warm, comforting experience.

The control panel is intuitive, allowing operators to adjust the temperature and pressure with ease. This isn’t just a sandwich press; it’s a precision tool that can cater to a variety of recipes and preferences. Whether you’re crafting a classic grilled cheese or a gourmet panini, this press can do it all.

But it’s not just about the technical aspects. The NSF approval is a stamp of excellence that speaks volumes about the press’s ability to meet stringent health and safety standards. In the commercial kitchen, where hygiene is paramount, this certification is a game-changer. It gives chefs and restaurant owners peace of mind, knowing that they’re using a product that has been rigorously tested and approved.

The press itself is a marvel of engineering. The non-stick surfaces ensure that sandwiches release smoothly, reducing the risk of sticking and making clean-up a breeze. The handles are ergonomically designed for comfort, and the compact size means it can fit seamlessly into any kitchen setup, from the smallest café to the largest fast-food chain.

But let’s talk about the culinary possibilities. This sandwich press isn’t just for sandwiches. Think about the endless possibilities it opens up for breakfast items, wraps, and even small appetizers. The even heat and consistent pressure mean that each piece of food is cooked to perfection, with a professional finish that will impress customers and colleagues alike.

In the fast-paced world of food service, innovation is key. The NSF Approved Commercial Sandwich Press is a testament to that. It’s not just a tool; it’s a symbol of progress. It’s a nod to the future of quick-service restaurants, where speed, quality, and safety are paramount.

As chefs and restaurateurs look for ways to differentiate their offerings, this sandwich press could be the edge they need. It’s not just about making sandwiches; it’s about creating an experience. It’s about offering customers something that’s not just delicious but also visually appealing and consistently prepared.

The culinary scene is constantly evolving, and the introduction of the NSF Approved Commercial Sandwich Press is a clear sign that we’re moving towards a future where technology and tradition go hand in hand. It’s not just a press; it’s a statement about the direction the industry is heading, one where innovation is celebrated and embraced.

So, if you’re in the market for a sandwich press that can take your kitchen to the next level, look no further. The NSF Approved Commercial Sandwich Press is more than just a tool; it’s a partner in your quest for culinary excellence. It’s time to toast to innovation and the possibilities that this new press brings to the table.

The National Sanitation Foundation (NSF) certification is not just a label; it’s a gold standard in the commercial kitchen industry. This rigorous approval process ensures that products meet specific health and safety requirements, and it’s a testament to a product’s quality and reliability. For commercial kitchens, understanding the NSF certification is crucial for several reasons.

The NSF certification process involves a thorough examination of a product’s design, materials, manufacturing, and performance. This includes rigorous testing for safety, hygiene, and efficiency. Products that earn this certification have been evaluated against stringent criteria that are recognized and respected worldwide.

In the context of commercial kitchens, where hygiene and safety are paramount, the NSF certification is a crucial factor. It guarantees that the sandwich press you’re using meets the highest standards for cleanliness, reducing the risk of foodborne illnesses. This is especially important in high-traffic areas where the potential for cross-contamination is higher.

One of the key aspects of the NSF certification is the emphasis on material safety. The certification ensures that the materials used in the sandwich press are non-toxic and do not leach harmful substances into the food. This is particularly relevant in the food service industry, where the integrity of the food product is non-negotiable.

Moreover, the NSF certification also covers the performance of the sandwich press. It ensures that the product operates as intended, delivering consistent and reliable results. This means that the sandwich press not only looks good but also performs consistently, which is essential for maintaining a high level of service quality in commercial kitchens.

For operators of commercial kitchens, the NSF certification is a trust mark. It provides reassurance that the product has been independently evaluated and meets the strictest industry standards. This can be a significant differentiator when it comes to attracting customers who are looking for a safe and hygienic dining experience.

Additionally, the NSF certification can also have legal implications. In some jurisdictions, it may be a requirement for certain types of food service equipment. Having this certification on your sandwich press means you are compliant with local regulations, avoiding potential fines and legal issues.

The certification also extends to the manufacturing process. It ensures that the sandwich press is produced in a facility that adheres to strict quality control measures. This not only guarantees the longevity of the product but also ensures that it will perform as expected over its lifetime.

Another important aspect of the NSF certification is its ongoing nature. Products are subject to regular audits and re-testing to maintain their certification status. This ongoing commitment to quality and safety is a reassurance to both the manufacturer and the end-user that the sandwich press will continue to meet the highest standards.

For the end-user, the NSF certification means peace of mind. It’s a clear indicator that the sandwich press is built to last, will perform as advertised, and will contribute to a safe and efficient kitchen environment. This can also translate into cost savings in the long run, as there are fewer repairs and replacements needed.

In summary, the NSF certification is a critical component for any commercial kitchen that values safety, quality, and compliance. It’s not just a label on a product; it’s a symbol of the manufacturer’s dedication to excellence and a commitment to providing a safe and hygienic environment for both staff and customers. Whether it’s the materials used, the performance of the product, or the manufacturing process, the NSF certification ensures that the sandwich press is a reliable and trusted tool in the commercial kitchen arsenal.

The new NSF approved commercial sandwich press is not just a tool; it’s a game-changer in the culinary world. Crafted with precision and innovation, this sandwich press boasts a range of features and benefits that elevate the art of sandwich making to new heights.

Superior Heat Retention and Uniform DistributionThe heart of this sandwich press lies in its advanced heat retention capabilities. The non-stick surface ensures that heat is evenly distributed across the entire sandwich, leading to a perfectly toasted outer crust and a juicy, tender interior. This feature is particularly crucial in commercial settings where consistency is key, and customers expect nothing but the best.

Durable and Robust ConstructionBuilt to withstand the rigors of a busy kitchen, the sandwich press is constructed from high-quality materials. Its sturdy build guarantees longevity, even with frequent use. The press’s solid construction also means it can handle a variety of sandwich sizes and weights, from thin deli sandwiches to hearty gourmet creations.

User-Friendly Design for Effortless OperationOne of the standout features of this sandwich press is its intuitive design. The handle is ergonomically shaped for a comfortable grip, reducing hand fatigue during extended use. The smooth, seamless surfaces prevent food particles from getting stuck, making cleaning a breeze. This user-friendly approach ensures that kitchen staff can focus on creating delicious sandwiches rather than dealing with complex machinery.

Non-Stick Coating for Easy Food ReleaseThe non-stick coating on the sandwich press is a game-changer for any commercial kitchen. It ensures that sandwiches slide off the press effortlessly, without any risk of tearing or sticking. This not only improves the quality of the final product but also saves time and reduces the likelihood of food waste.

Multiple Heat Settings for VersatilityUnderstanding that not every sandwich requires the same level of toasting, the sandwich press offers multiple heat settings. Whether you’re crafting a classic ham and cheese or a gourmet avocado toast, the ability to adjust the heat to your exact preference ensures that each sandwich is tailored to perfection.

Quick and Efficient CookingTime is of the essence in commercial kitchens, and this sandwich press delivers on speed and efficiency. The compact design and quick heat-up time mean you can start pressing sandwiches almost immediately. This feature is particularly beneficial during peak hours, when every minute counts.

Safety Features for Peace of MindSafety is paramount in any kitchen, and the new sandwich press is designed with this in mind. The press has a locking mechanism that prevents accidental closures, ensuring that fingers remain safe. Additionally, the cool-touch handles keep hands at a comfortable temperature, even after prolonged use.

Versatility in Sandwich VarietyFrom classic deli sandwiches to gourmet sliders and breakfast sandwiches, this sandwich press can handle a wide array of ingredients and fillings. The ability to press different types of bread, from brioche to ciabatta, expands the possibilities for kitchen creativity and caters to diverse customer preferences.

Enhanced Presentation with Crisp EdgesThe even toasting and crisp edges that the sandwich press provides are not just about taste; they also enhance the presentation of each sandwich. A well-presented sandwich is more appealing to customers, and this press helps restaurants stand out in a competitive market.

Eco-Friendly and SustainableThe sandwich press is designed with sustainability in mind. The materials used are not only durable but also environmentally friendly, contributing to a greener kitchen operation. This is a small but significant step towards a more sustainable future in the foodservice industry.

In conclusion, the new NSF approved commercial sandwich press is a marvel of modern culinary technology. Its combination of advanced features, ease of use, and ability to produce high-quality sandwiches makes it an essential tool for any commercial kitchen looking to revolutionize their sandwich making capabilities.

The NSF Approved Sandwich Press is a marvel of modern culinary technology, designed to elevate the art of sandwich making in commercial kitchens. Here are some of its standout features:

Precision Pressure Mechanism: The sandwich press boasts a precision pressure mechanism that ensures every sandwich is uniformly pressed. This feature guarantees that each layer is sealed perfectly, locking in the flavors and textures for a delectable final product.

Adjustable Temperature Control: With a range of temperature settings, this press caters to various types of bread and fillings. Whether you’re crafting a simple ham and cheese or a gourmet option with avocado and bacon, the adjustable temperature allows for perfect cooking each time.

Non-Stick Coating: The interior of the sandwich press is lined with a high-quality non-stick coating, making it easy to clean and ensuring that your sandwiches release effortlessly, without sticking or tearing the bread.

Ergonomic Handle: Designed for comfort and ease of use, the ergonomic handle allows chefs to operate the press with minimal effort. This feature is especially beneficial when working with large batches or during busy shifts.

Rapid Heat-Up Time: The sandwich press heats up quickly, reducing downtime and keeping your kitchen running smoothly. This feature is particularly advantageous during peak hours when speed and efficiency are crucial.

Safety Locking Mechanism: A safety locking mechanism is integrated into the design to prevent accidental openings during use. This ensures that the press remains secure and safe to use, reducing the risk of burns or injuries.

Durable Construction: Built to withstand the demands of commercial kitchens, the sandwich press is made from high-grade materials that are resistant to corrosion and heat. Its robust construction ensures a long lifespan, even with frequent use.

Large Cooking Surface: The expansive cooking surface of the press allows for the preparation of sandwiches of varying sizes, from individual servings to those suitable for larger groups. This versatility is perfect for both high-volume operations and catering events.

Easy to Clean and Maintain: The sandwich press is designed with maintenance in mind. The non-stick surface and removable parts make cleaning a breeze, ensuring that the press stays in top condition and continues to deliver exceptional results.

Energy Efficiency: The press is designed to be energy-efficient, minimizing power consumption while maintaining optimal cooking temperatures. This not only saves on utility bills but also contributes to a more sustainable kitchen environment.

Hygiene and Sanitation: The NSF certification also guarantees that the sandwich press meets strict hygiene and sanitation standards. This is essential for maintaining a safe and healthy kitchen, protecting both customers and staff.

Versatile Cooking Options: In addition to making sandwiches, the press can also be used to prepare other items like grilled cheese, melts, and even small paninis. Its versatility expands the menu options available to chefs and caterers.

Professional-Grade Performance: With its advanced features and durable design, the NSF Approved Sandwich Press delivers professional-grade performance that is a match for any commercial kitchen.

Customer Satisfaction: The combination of quality, ease of use, and consistent results means that the sandwich press can significantly enhance customer satisfaction. By offering consistently delicious sandwiches, it contributes to a positive dining experience.

Warranty and Support: To provide peace of mind, the sandwich press comes with a comprehensive warranty and excellent customer support. Should any issues arise, the manufacturer is readily available to assist and ensure that your investment is protected.

The culinary industry has been buzzing with the introduction of the new NSF Approved Sandwich Press. Market reactions have been overwhelmingly positive, with chefs and restaurateurs alike praising the innovative features and the potential it brings to the sandwich-making process. Here’s a snapshot of what the market is saying:

Customers are raving about the consistent quality and uniformity the press delivers. The ability to achieve a perfectly grilled sandwich every time, without the hassle of uneven cooking, has been a game-changer for many. The consistent texture and temperature of the bread, meat, and condiments have led to higher customer satisfaction and repeat visits.

Industry experts have highlighted the efficiency gains that come with this new technology. The time saved by not having to manually press sandwiches means staff can focus on other tasks, improving overall kitchen workflow. This efficiency has been particularly beneficial for busy restaurants and cafes looking to maximize their service without compromising on quality.

The health and safety aspect of the NSF certification has not gone unnoticed. The market is praising the sandwich press for its adherence to strict sanitation standards, which is crucial in commercial kitchens where food safety is paramount. The press’s easy-to-clean surfaces and the assurance of consistent cooking temperatures help reduce the risk of foodborne illnesses, which is a major concern for both operators and consumers.

Innovation is a buzzword in the culinary scene, and the new sandwich press is being hailed as a beacon of creativity in the industry. Chefs are exploring new flavors and combinations, knowing that the press will deliver the results they need. From gourmet options to the classics, the press has opened up a world of possibilities, allowing chefs to push the boundaries of sandwich making.

Restaurateurs are seeing the sandwich press as a strategic investment. With the potential to attract a wider customer base and appeal to health-conscious diners looking for fresh, high-quality sandwiches, the press is seen as a tool that can help differentiate their establishment in a crowded market. The press’s ability to create a visually appealing and appetizing sandwich is a powerful draw for customers.

From a cost perspective, the market is noting the long-term savings that the sandwich press can provide. While the initial investment may be higher than traditional sandwich presses, the durability and energy efficiency of the new model are expected to lead to lower maintenance and energy costs over time. This has made the sandwich press an attractive option for businesses looking to optimize their operations.

Environmental sustainability is also a key factor in the market’s response. The sandwich press’s eco-friendly design, including its use of sustainable materials and energy-efficient operation, has been commended. Operators are looking to reduce their carbon footprint, and this press offers a solution that aligns with their environmental goals.

In conclusion, the market’s response to the NSF Approved Sandwich Press has been overwhelmingly positive. The combination of efficiency, safety, innovation, and sustainability has positioned this new tool as a must-have for any commercial kitchen serious about delivering exceptional sandwiches to their customers. The excitement is palpable, and the culinary industry is eagerly awaiting to see how this game-changing press will shape the future of sandwich making.

The NSF Sandwich Press isn’t just a tool for making sandwiches; it’s a versatile kitchen gadget that opens up a world of culinary possibilities. Here are some innovative ideas to maximize its potential in your kitchen:

Creating Artisanal Flatbreads: The even pressure and precise heat of the press can be perfect for crafting homemade flatbreads. Simply shape your dough, add your toppings, and press for a crisp, evenly toasted flatbread that’s as delicious as it is impressive.

Perfecting Pizza: Whether you’re a pizza enthusiast or a professional chef, the sandwich press can be a game-changer for homemade pizzas. Load your dough into the press, add your sauce, cheese, and toppings, and press out a uniformly golden crust that’s ready for baking.

Grilling Mini Burgers: Transform your sandwich press into a mini-grill for gourmet mini-burgers. Load the press with burger patties, top them with your favorite grilled vegetables, and press for a perfectly charred, juicy bite-sized burger.

Crafting Mini Sandwiches and Canapes: The compact size of the press makes it ideal for making mini sandwiches and canapes for parties or as a convenient snack. You can create bite-sized versions of classic sandwiches or experiment with new flavor combinations.

Customized Breakfast Pastries: Use the sandwich press to make breakfast pastries like mini quiches or breakfast sandwiches. Simply press the ingredients together, and you’ll have a portable, perfectly formed breakfast that’s perfect for on-the-go mornings.

Making Sushi: The sandwich press can also be used to press sushi rice into a uniform block, making it easier to roll and shape into sushi rolls or nigiri. This can be particularly useful for home chefs looking to perfect their sushi-making skills.

Grilled Cheese Variations: Beyond the classic grilled cheese, the sandwich press can be used to make gourmet grilled cheese sandwiches with different cheeses, spreads, and toppings like avocado, prosciutto, or fig jam.

Mini Quesadillas: For a quick and easy appetizer or snack, press out mini quesadillas with your favorite fillings. It’s a fun and interactive way to enjoy a quesadilla, especially for kids or at a party.

Seasonal and Themed Sandwiches: Use the sandwich press to create themed sandwiches for different seasons or holidays. For example, press out sandwiches with autumnal themes using pumpkin seeds, cranberry jam, and spiced cheese.

Homemade Pitas: The sandwich press can be used to make homemade pita bread. Simply press out the dough, add your fillings, and press for a pita that’s perfect for wraps, sandwiches, or falafel.

Caramelized Cheese Platters: For a sophisticated appetizer, press different types of cheese in the sandwich press with a sprinkle of caramelized onions or apple slices for a delightful contrast of flavors.

Protein-Packed Breakfast Wraps: Fill the sandwich press with a protein-rich mix of eggs, spinach, and cheese, and press for a breakfast wrap that’s perfect for a quick and healthy start to the day.

By thinking outside the sandwich box, the NSF Sandwich Press can become a staple in your kitchen, offering a myriad of creative and delicious options for both casual meals and special occasions.

The NSF Sandwich Press has quickly become a staple in the commercial kitchen, and for good reason. Here’s how it distinguishes itself from the competition:

The press boasts a robust build that’s designed to withstand the rigors of daily use in a busy kitchen. Its durable construction means it can handle heavy-duty sandwiches without succumbing to wear and tear. This longevity not only ensures a reliable tool but also reduces the need for frequent replacements, making it a cost-effective investment for any commercial kitchen.

Heat distribution is crucial in the art of sandwich making, and the NSF Sandwich Press delivers on this front. With its even heat technology, it ensures that every sandwich is cooked to perfection, with a golden-brown crust and a melting cheese that oozes out. This consistency is something that manual pressing often lacks, making the NSF model a favorite among chefs who demand top-notch quality.

Ease of use is often overlooked in commercial kitchen equipment, but not with the NSF Sandwich Press. It features a simple, intuitive design that makes it easy to operate, even for those not as familiar with kitchen appliances. The smooth operation and straightforward controls ensure that the staff can focus on their primary tasks without the hassle of dealing with a complicated machine.

The NSF Sandwich Press comes with non-stick surfaces that not only make cleaning a breeze but also prevent food from sticking, ensuring that every sandwich comes out looking and tasting its best. This feature is a game-changer for kitchens that are short on time and need to maintain a high level of cleanliness and hygiene.

Safety is a top priority in commercial kitchens, and the NSF Sandwich Press doesn’t compromise on this aspect. It includes features like a safety lock to prevent accidental activation, as well as an automatic shut-off function that turns off the press if it detects that it’s not being used. These safety features provide peace of mind for kitchen staff and patrons alike.

The press’s compact size is another standout feature. It’s designed to fit seamlessly into any kitchen setup, whether you have a lot of space or limited counter space. This compact design doesn’t mean it skimps on performance; it simply means it’s a versatile addition to any kitchen, from busy cafes to bustling restaurants.

The NSF Sandwich Press also offers customization options. It comes with interchangeable plates that allow you to press different types of sandwiches, from classic deli sandwiches to gourmet creations. This flexibility is a hit with chefs who are always looking to offer something new and exciting to their customers.

In terms of energy efficiency, the NSF Sandwich Press is a leader in its class. It’s designed to use energy responsibly, which not only helps to reduce utility bills but also aligns with the growing trend towards sustainability in the culinary industry.

Customer feedback has been overwhelmingly positive. Users praise the press for its reliability, ease of use, and the quality of the sandwiches it produces. Chefs in particular have noted the consistency and the speed at which they can serve a high volume of sandwiches, which is essential for maintaining a quick service environment.

Finally, the NSF Sandwich Press is a testament to the brand’s commitment to quality and innovation. By adhering to strict NSF standards, the company ensures that its customers are getting a product that meets the highest safety and performance criteria. This dedication to excellence is what has set the NSF Sandwich Press apart in the competitive commercial kitchen appliance market.

In the culinary world, where the smallest details can make the biggest difference, the NSF Sandwich Press has been turning heads. Here are stories from chefs and restaurant owners who have embraced this innovative tool, sharing their experiences and the tangible impact it’s had on their businesses.

“The first time I used the NSF Sandwich Press, I was amazed at how much it streamlined our sandwich-making process. The even pressure ensures that every sandwich is perfectly toasted and holds together beautifully.” – Chef Maria, Urban Deli

Chef Maria’s enthusiasm is a common sentiment among those who’ve adopted the NSF Sandwich Press. The precision of the press means that no two sandwiches are alike, maintaining consistency across the board. This consistency has been a game-changer for her kitchen, as it’s crucial for keeping her customers happy and loyal.

“Before the NSF Sandwich Press, we were constantly battling with soggy bread and uneven toasting. Now, every sandwich comes out crisp and golden, thanks to the even distribution of heat. It’s like a game of chess – one wrong move, and the whole game is lost. With this press, the game is won every time.” – Chef Alex, The Gourmet Grille

Chef Alex’s comments highlight the pressing need for reliable equipment in the kitchen. The NSF Sandwich Press has not only improved the quality of their sandwiches but has also reduced waste and saved time. The efficiency gained from using this press has allowed his kitchen staff to focus on other tasks, enhancing the overall service quality.

“I was skeptical at first, but the NSF Sandwich Press has proven to be a valuable asset. It’s not just about the sandwiches; it’s about the entire dining experience. When customers see a perfectly pressed sandwich, it makes our menu more appealing, and that translates to more sales.” – John, The Sandwich Shop

John’s testimonial underscores the importance of presentation in the food industry. The visual appeal of a well-pressed sandwich can significantly boost sales and customer satisfaction. The NSF Sandwich Press has become a centerpiece in his kitchen, not just for its functionality but for the positive impact it has on the dining experience.

“The best part about the NSF Sandwich Press is its versatility. We started using it for our sandwiches, but then we realized it could be used for other items on our menu. It’s like having a secret weapon in the kitchen.” – Chef Sarah, The Bistro

Chef Sarah’s insight into the multifunctionality of the NSF Sandwich Press is shared by many. This press has become more than just a sandwich-making tool; it’s a versatile piece of equipment that can enhance the quality of various dishes. From burgers to wraps, the press has expanded the creative possibilities in her kitchen.

“I’ve tried other sandwich presses, but the NSF model is by far the best. It’s well-built, easy to clean, and the heat control is exceptional. It’s a pleasure to use every day, and it’s made my job much easier.” – Emily, Local Eatery

Emily’s positive experience with the NSF Sandwich Press reflects the high standards expected in commercial kitchens. The ease of use and the high quality of the press have made a significant difference in her daily operations. Her satisfaction with the product is a testament to the attention to detail that NSF brings to their manufacturing process.

“The NSF Sandwich Press has become an essential part of our kitchen. It’s not just about the quality of the sandwiches we serve; it’s about the speed at which we can serve them. This press has allowed us to keep up with the high demand during peak hours without compromising on quality.” – Mike, The Diner

Mike’s observation about the press’s ability to maintain quality while increasing speed is a crucial factor in the fast-paced world of food service. The NSF Sandwich Press has not only helped his establishment stay competitive but has also improved customer satisfaction by reducing wait times.

In a world where innovation meets practicality, the NSF Sandwich Press has emerged as a favorite among chefs and restaurant owners. The real-world applications of this product are nothing short of transformative, as each testimonial highlights the benefits it brings to the culinary industry. Whether it’s the consistency, versatility, or the overall ease of use, the NSF Sandwich Press is making waves and earning its place as a must-have tool in any commercial kitchen.

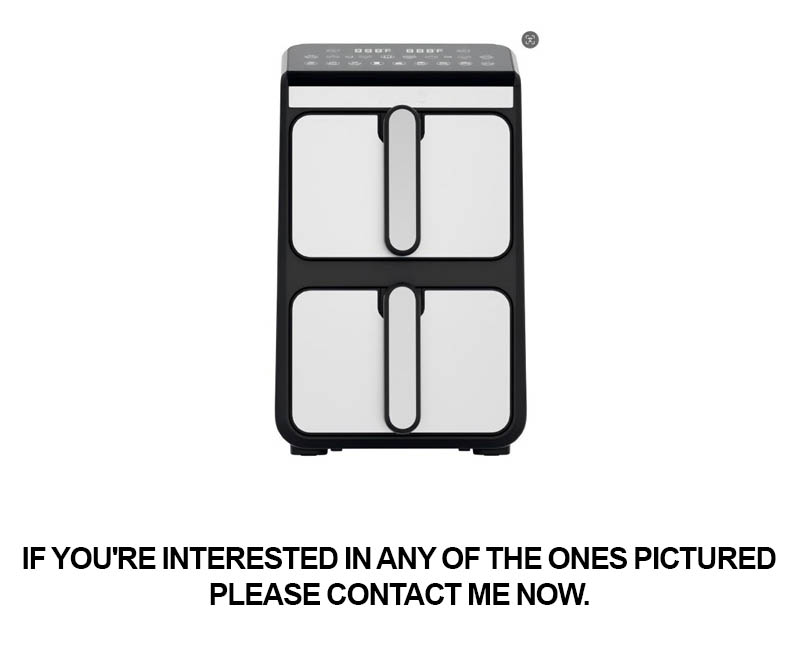

In the ever-evolving culinary landscape, commercial sandwich presses have become a staple in the preparation of delectable sandwiches. As technology advances, the future of these sandwich-making tools is shaping up to be both innovative and efficient. Here are some of the future trends in commercial sandwich press technology:

Smart Automation: Imagine a sandwich press that not only cooks your sandwiches to perfection but also learns from your preferences. With smart automation, these presses could be programmed to adjust cooking times, temperatures, and even the pressure applied to ensure each sandwich is cooked just right.

Energy Efficiency: As sustainability becomes a growing concern, the next generation of commercial sandwich presses will likely be designed with energy efficiency in mind. Expect to see appliances that use less power while still delivering high-quality results, contributing to a greener kitchen environment.

Multi-Functionality: The future of sandwich presses may include a range of features beyond just pressing sandwiches. These could include toasting bread, melting cheese, and even grilling vegetables, all in one compact unit. This multi-functionality would save space and streamline the cooking process.

Enhanced Safety Features: With the health and safety of both staff and customers being paramount, future sandwich presses are expected to incorporate advanced safety features. This might include anti-scalding handles, childproof locks, and automated shut-off mechanisms to prevent accidents.

Customizable Pressing Patterns: While the classic flat pressing is beloved by many, the future could bring a variety of pressing patterns. These could include ridges for added texture, holes for a grilled effect, or even customizable shapes to cater to specific menu items.

Wireless Connectivity: As kitchens become more connected, sandwich presses may soon be able to sync with kitchen management systems. This would allow for remote monitoring and control, as well as integration with inventory management to optimize the use of ingredients.

Eco-Friendly Materials: The materials used in the construction of commercial sandwich presses are also set to change. We could see a shift towards more sustainable and recyclable materials, reducing the environmental impact of kitchen equipment.

Enhanced Cooking Uniformity: The key to a great sandwich is even cooking across the entire surface. Future presses may employ advanced heating elements and sensors to ensure that every sandwich is cooked consistently, from the crust to the fillings.

Personalization Options: Catering to the diverse tastes of consumers, future sandwich presses might offer a range of personalization settings. Chefs could select different levels of doneness, crustiness, and even the type of press that best suits the sandwich’s final texture.

Interactive User Interfaces: The interface of the sandwich press might evolve to be more interactive, with touchscreens or even voice commands to simplify the cooking process. This would make the appliance more accessible to all kitchen staff, regardless of their technical expertise.

Modular Design: To cater to different kitchen layouts and needs, sandwich presses may come in modular designs. This would allow for custom configurations, where individual units can be combined or reconfigured as required.

Health and Wellness Focus: As health trends continue to influence the food industry, sandwich presses might be developed with features that cater to specific dietary needs. This could include adjustable settings for different types of bread and fillings, or even the ability to cook sandwiches with minimal added fats.

Real-Time Data Analysis: With the integration of IoT (Internet of Things) technology, sandwich presses could provide real-time data on cooking performance, usage patterns, and maintenance needs. This data could help kitchens optimize their operations and predict maintenance before issues arise.

Smart Cleaning and Maintenance: To reduce the time spent on cleaning and maintenance, future sandwich presses might incorporate self-cleaning functions. These could use steam or other eco-friendly cleaning agents to keep the appliance in top condition without the need for harsh chemicals.

As the culinary industry continues to push boundaries, the future of commercial sandwich press technology promises to be both exciting and practical. With these trends, the humble sandwich press could soon be a marvel of modern kitchen innovation.

In the ever-evolving culinary landscape, embracing innovation is key to staying ahead. The NSF Approved Sandwich Press represents a leap forward in commercial kitchen technology, and its impact is already being felt across the industry. As we look back at the journey this game-changing tool has taken us on, it’s clear that it’s not just a sandwich press—it’s a symbol of the future of foodservice.

The NSF Certification, which stands for National Sanitation Foundation, is a stamp of approval that signifies a product meets rigorous standards for health, safety, and performance. In the context of a commercial sandwich press, this certification is not just a formality; it’s a guarantee that the equipment is reliable, durable, and designed to maintain the highest standards of food safety.

One of the standout features of the NSF Sandwich Press is its precise heat control. Designed with a focus on even heat distribution, this press ensures that every sandwich is cooked to perfection, with a crispy outside and a tender inside. The non-stick surfaces and stainless steel construction not only make cleaning a breeze but also contribute to the longevity of the appliance.

The compact and user-friendly design of the NSF Sandwich Press has been praised by chefs and kitchen staff alike. Its intuitive controls and easy-to-fill reservoir make it an excellent choice for both busy kitchens and those looking to streamline their workflow. The press’s ability to accommodate a variety of sandwich sizes and shapes means it’s not just limited to the traditional 6-inch sandwich; it can handle larger, more creative options with ease.

The market response to the NSF Sandwich Press has been overwhelmingly positive. Restaurant owners are seeing increased customer satisfaction as the consistency and quality of their sandwiches improve. Chefs are delighted with the speed and efficiency of the press, allowing them to focus on other aspects of their craft. The fact that the press is also versatile enough to be used for grilling, toasting, and even searing means it’s a valuable addition to any kitchen, whether it’s a fast-food establishment or a fine dining restaurant.

Innovation in the sandwich press market doesn’t stop at the NSF Approval. The latest models are integrating smart technology, such as touchscreens for precise temperature control and connectivity options for data tracking and maintenance alerts. These advancements not only enhance the user experience but also contribute to the sustainability of the kitchen, reducing energy consumption and minimizing waste.

One of the most exciting developments in commercial sandwich press technology is the introduction of modular designs. These presses can be customized with different attachments and accessories, allowing kitchens to tailor their equipment to their specific needs. Whether it’s a bakery looking to create perfectly grilled sandwiches or a food truck operator in need of a compact, portable press, the modular approach ensures that the equipment is adaptable to any kitchen environment.

The impact of the NSF Sandwich Press on the culinary industry is significant. It has sparked a renewed interest in the art of the sandwich, pushing chefs to experiment with new flavors and techniques. The press has also become a favorite among food enthusiasts who appreciate the convenience and quality of a freshly made sandwich. Its versatility means it can be found in a variety of settings, from diners and cafes to gourmet food markets and even corporate cafeterias.

In terms of sustainability, the NSF Sandwich Press is a leader. Its energy-efficient design and durable construction mean that it can withstand the rigors of a busy kitchen without contributing to environmental degradation. The ability to easily replace worn-out parts and the fact that the press is made from recyclable materials make it an eco-friendly choice for any commercial kitchen.

As we look to the future, the trend in commercial sandwich press technology is clear: it’s all about customization, efficiency, and sustainability. The NSF Sandwich Press has set a precedent for what’s to come, and it’s likely that we’ll see even more innovative solutions in the years ahead. From AI-driven predictive maintenance to presses that can be controlled remotely, the possibilities are endless.

In conclusion, the NSF Approved Sandwich Press is more than just a piece of equipment; it’s a testament to the power of innovation. It has redefined what’s possible in sandwich preparation, offering a level of consistency, efficiency, and health safety that is unmatched in the industry. As kitchens continue to evolve, the Sandwich Press will undoubtedly remain a key player, inspiring new culinary creations and setting new standards for excellence.